Multiaxial and Multiscale Plasticity in Metals

In this ERC funded project, our ambition is to probe the influence of non-proportional multiaxial straining on the multiscale aspects of metal plasticity with focus on three deformation mechanisms: dislocation plasticity, mechanical twinning, and martensitic phase transformation. The objective is gain ground-breaking insight on how a second strain path, a change in strain path with or without prior unloading affects the operation of the deformation mechanism and the microstructure evolution. (More)

Origin of the internal stress in 18 cts gold alloys

The goal of this project is to establish a link between internal stresses in 3N and 5N 18 cts gold alloys at various stage of their processing steps in order to determine understand its origin and suggest paths to reduce residual stresses during manufacturing. (More)

Additive Manufacturing and Metallic Microstructures (AM3)

The aim of the AM3 challenge is to address the fundamental materials science problems that underlie the transition from traditional manufacturing techniques to additive manufacturing (AM), with a specific focus on metallic alloys, and the relation between process, microstructure and properties. (More)

Characterization of defects by advanced X-ray diffraction techniques to evaluate deformation stages in micro-crystals

This project aims at gaining a detailed understanding of the mechanics of small scale objects by the implementation of a combination of in situ coherent X-ray diffraction, in situ micro-Laue diffraction, post-mortem Bragg ptychography and ptychographic topography. (More)

Creep resistant nanocrystalline materials

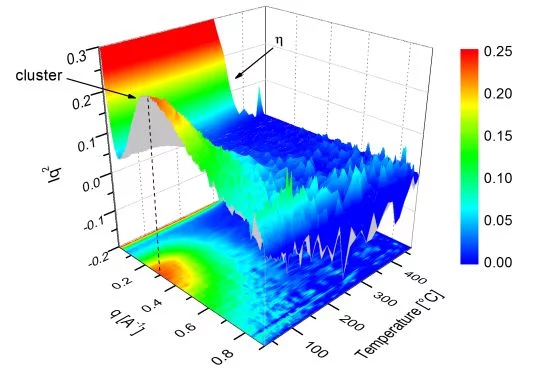

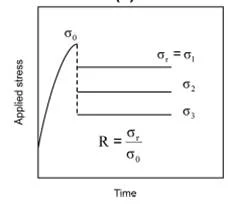

The goal of this project is to develop a creep resistant material for the fabrication of micromechanical LiGA-based springs. The strategy followed in this project is inspired by the results of the PhD research of Mrs. Zhen Sun, where stress-drop experiments carried out insitu during xray diffraction demonstrated the competition between dislocation and grain boundary relaxation based mechanisms. (More)

Improving the Bendability of 6000 series Al Alloys by Microstructural Optimisation

The aim is to improve the bendability of Al alloys which are used in car body panels. In order to do so, the formation and evolution of the secondary phases of Al alloys during casting and homogenisation will be studied, as the presence of the secondary phases strongly influences the deformation mechanism of the Al alloy. (More)

Strategic Focus Area Advanced Manufacturing

Within this program PEM participates in 3 projects financed within the Precision Free-Form Manufacturing - TFA 1 : PREAMPA, FUORCLAM and CERAMIC X.0 by developing new insitu experiments and using the advanced characterization techniques available at the Swiss Light Source (SLS) and the Swiss Neutron Spallation Source (SINQ). (More)

Finished research projects

| Project | Description |

|---|---|

| Mechanical properties of nanocrystalline metals | Nanocrystalline metals exhibit remarkable mechanical properties compared to their coarse-grained counterparts. The underlying mechanisms are still under debate, especially for the smallest grain sizes. In this project in-situ mechanical testing during x-ray diffraction is employed to investigate the evolving microstructure. More |

| Deformation mechanisms in bcc single crystals | A unique combination of micro-compression of single crystal micro-pillars and Laue micro-diffraction is employed to investigate the active slip systems in various body centered cubic metals. More |

| Heat treatable Al alloys | Measurements and modelling of residual stresses during quenching of thick heat treatable aluminium components in relation to their microstructure. More |

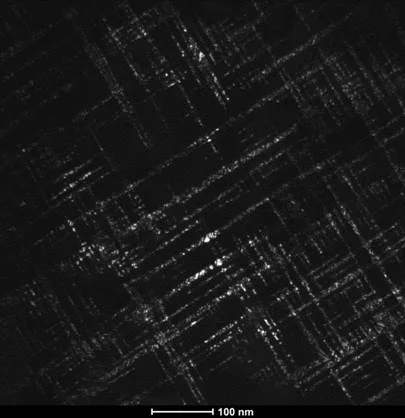

| Nano-silver as bonding material | Investigate the microstructure and thermo-mechanical properties of nano porous sintered polycrystalline Ag layers using various techniques including in-situ x-ray diffraction, nano-tomography, ptychography and electron microscopy. A 3D microstructure based simulation is applied to allow a better correlation between the porous morphology and mechanical behavior. The outcome of these experiments will be used to generate a lifetime prediction model for sintered die-attachments. |

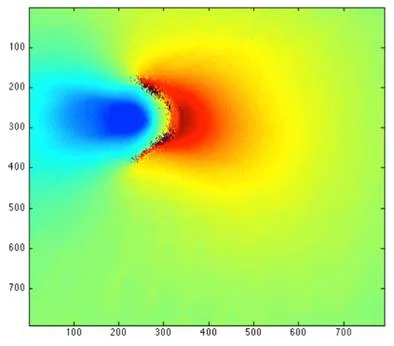

| Cyclic plasticity in shear | Understand the evolution of dislocation patterning occurring in the earlier phases of fatigue before the saturation stage is reached. Crystal rotation caused by the emerging dislocation structures and GND density distribution are analyzed in fcc single crystals. This is done with Laue diffraction during in-situ reversed-shear deformation at the microXAS beamline of the Swiss Light Source. For achieving this purpose a new miniaturized shear device and designed suitable sample geometry have been developed. The project is part of a collaborative project titled “Constitutive modelling and microstructural validation for crystal plasticity finite element (CPFE) computation of cyclic plasticity in fatigue” (SNF – 138240). |

| POLDI detector upgrade | Development of a ZnS/6LiF scintillation detector for simultaneous measurement of axial and transverse strain in collaboration with the detectors group and the electronics and measuring systems group. More |

| Bottom-up Laue diffraction | Calculation of Laue diffraction spots from dislocation ensembles simulated by dislocation dynamics. More |

| Development of residual strain in bainitic steel | The accumulation of residual strain during room temperature and high temperature deformation of a 1%CrMoV steel is studied by advanced in-situ x-ray and neutron diffraction techniques. |

| Microstructure of single crystal Ni-based superalloys | The aim of this project is to obtain profound understanding on the influence of plastic deformation on the microstructural changes observed in single crystal Ni-based superalloys using diffraction techniques. |

| The color of Gold | With an ever-growing interest in the luxury industry for innovations, the development of new colors in precious alloys has become of strategic importance as a major differentiating factor for brands. However, the development of innovative alloys, featuring new colors by addition of non-classical alloying elements is tedious and expensive if large empirical screenings of compositions have to be executed. This project addresses this issue by ab initio modeling effort for color prediction More |

| Atomistic simulations of nanocrystalline metals | The investigation of the influence of the triple junctions and the accommodation processes in the surrounding GBs on coupled grain boundary motion More |