Overview

The Laboratory of Atmospheric Chemistry (LAC) at the Paul Scherrer Institute (PSI) is host to the PSI Atmospheric Simulation Chambers and Reactors (PACS) facilities, the largest atmospheric simulation chamber and reactor facility in Switzerland. This cutting-edge combination of atmospheric simulation chambers and flow tube reactors can be used to investigate real-world atmospheric processes under highly controlled conditions. Our research at LAC is centered on using PACS for the study of atmospheric aerosol including their characterization as part of complex real-world emissions, and their formation and aging, through oxidation mechanism studies of gaseous pollutants and secondary organic aerosol (SOA).

Specific questions our research aims to address include:

- Investigation of oligomer formation in SOA

- Determination of SOA yields from various biogenic and anthropogenic precursor compounds

- Molecular and bulk composition investigation of organic aerosol, including the impact on aerosol volatility

- Evaluation of photochemical mechanisms

- Characterization of complex emissions (e.g. residential burning of wood, coal, plastic, and cow-dung, open biomass burning, and fossil fuel burning)

- Investigation of SOA formation from single precursors and complex real-world emissions

- Investigation of condensed phase processes and their impacts on aerosol chemical and physical properties

- Investigation of organic and inorganic phase interactions in aerosols

- Investigation of aqueous phase processes in atmospheric clouds

- Understanding the oxidative potential of various fresh and aged emissions

- Intercomparison of instruments

The PACS facilities are an integral part of the Aerosol, Clouds and Trace Gases Research Infrastructure (ACTRIS), and as such focus on producing high-quality data and information on short-lived atmospheric constituents related to aerosol, and on the processes leading to their variability, in controlled atmospheres. We also provide transnational access to PACs for partners from the industrial and academic sectors. The combination of stationary and mobile smog chambers and flow reactors, the emission facility and state-of-the-art instrumentations makes the PACs a unique facility worldwide.

Technical Description

PSI Smog chamber

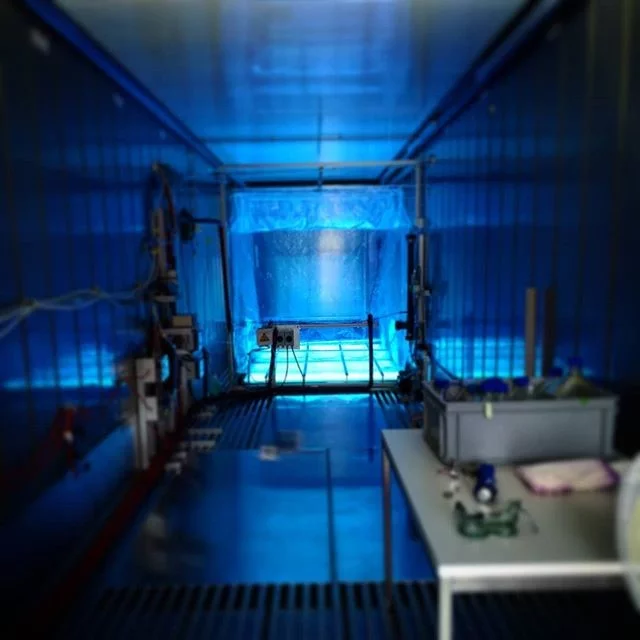

The smog chamber is a ~9 m³ (2 × 2 × 2.25 m) flexible chamber made of a Teflon® fluorocarbon film. The chamber is housed in a temperature controlled container, allowing for experiments to be conducted between -10 – 30°C, and within a temperature range of ±1 °C. The chamber is equipped with a series of 40 UV lights (λ ~350 nm) to initiate photochemistry within the solar actinic region, mimicking atmospheric conditions. The Teflon bag is suspended on rails, allowing it to expand or contract as air is injected into or sampled from the bag.

Purified air is supplied by an AADCO (737-250 series, AADCO Instruments, Inc., USA) pure air generation system up to 50 lpm . The humidity inside the chamber can be controlled with an ultrapure water bubbler system to obtain a relative humidity up to 100%. The chamber is equipped with a number of ports, allowing for delivery of gaseous components (such as NO, NO2, and gaseous organic compounds) to the smog chamber. The chamber is also equipped with ozone and HONO generators which can provide oxidants to the chamber in mixing ratios up to ppm levels. A particle generation system is also available for seed particle experiments. Finally, one of the heated ports is used to inject complex real-world emissions, including from our emission facility. A mobile version of the same chamber is also available for studying complex emissions outside PSI.

For a detailed description see:

-

Platt SM, El Haddad I, Zardini AA, Clairotte M, Astorga C, Wolf R, et al.

Secondary organic aerosol formation from gasoline vehicle emissions in a new mobile environmental reaction chamber

Atmospheric Chemistry and Physics. 2013; 13(18): 9141-9158. https://doi.org/10.5194/acp-13-9141-2013

DORA PSI

PSI oxidation flow reactor (OFR)

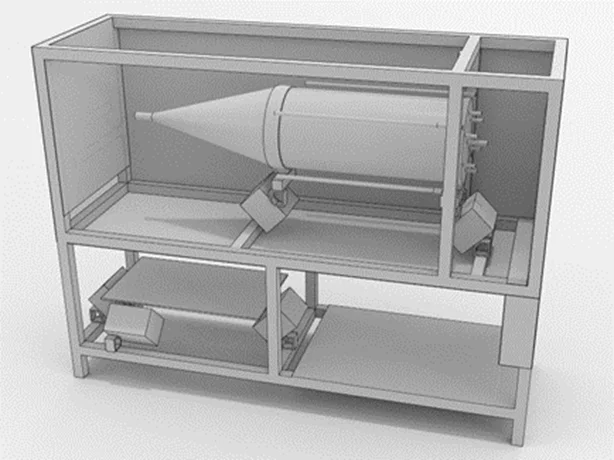

In addition to the “cool chamber” which enables studying aerosol aging on longer time frames, PACS also includes several flow reactors. The oxidation flow reactor (OFR) is used to simulate in few minutes atmospheric oxidation processes under controllable atmospheric exposure conditions, ranging from a day to 2 weeks. It comprises a sample injector, diffuser inlet, oxidation reactor, and outlet. The sample injection system can be coupled to the OFR for investigating single component or complex combustion sources, such as wood burning emissions.

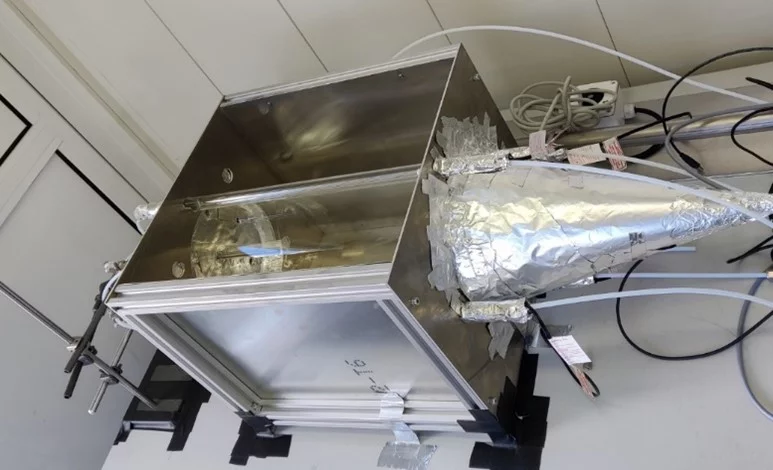

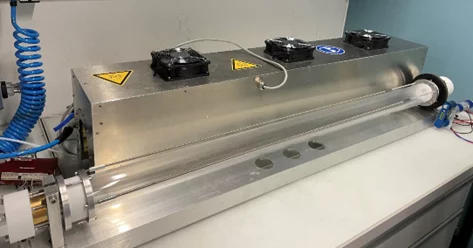

The conical diffuser inlet is 35.6 cm in length, with a full cone angle of 30˚ designed to minimize the impact of fluid jetting and recirculation. The main oxidation reactor is a 50.8 cm × 20.3 cm (inner diameter) fused quartz cylindrical tube, surrounded by 5 UV lamps (λ=254 nm) to photolyze ozone, and generate OH radicals with water vapor. To reduce the loss of gases and particles during sampling, the exhaust output is split into six openings, evenly spaced by 2.5 cm. The stainless-steel output port is located 12.7 cm inside of the reactor to avoid the influence of any potential turbulent eddies caused by the walls. The entire reactor is housed in a polished stainless-steel enclosure to ensure even and maximum photolysis. Similar to the smog-chamber the OFR can be operated at temperatures ranging between -10 and 30˚ C. A mobile version of the same OFR is also available for studying complex emissions outside PSI.

For a detailed description see:

Li K, Liggio J, Lee P, Han C, Liu Q and Li S-M; Secondary organic aerosol formation from α-pinene, alkanes, and oil-sands-related precursors in a new oxidation flow reactor, Atmospheric Chemistry and Physics. 2019; 19(15): 9715-9731. doi: 10.5194/acp-19-9715-2019

PSI wetted wall flow reactor (WFR)

The PSI wetted wall flow reactor (WFR) can be used to investigate aqueous-phase chemistry under relevant atmospheric cloud conditions. The WFR consists of a quartz glass cylinder (length: 125 cm, internal diameter: 6 cm), water injection system, Xe-excimer laser, and humidifier. The inner surface is sandblasted to increase the wettability of the glass, ensuring an evenly coated surface. At the end of the WFR, there is a water injection system, consisting of a tube connecting the quartz glass cylinder to the injector .The cylinder rotates at a speed of 15 rotations per minute, resulting in a water microlayer ranging from 35-250 µm thick. A stir bar (length: 123 cm, diameter: 3 mm) located at the bottom of the cylinder, facilitates the wetting of the wall surface, and the microfilm maintenance . The Xe-excimer laser (7.2 eV, 172 nm) is used to induce photolysis of H2O and O2, resulting in the formation of OH radicals, as well as O3 and HO2. To maintain a constant relative humidity (RH), an ultrapure dry air stream is passed through a porous PTFE Gore-Tex tube (Gore™) immersed in ultrapure water to keep a constant RH between 95% - 100%. RH is monitored with a hydroclip probe (Rotronic HygroClip). The temperature of the WFR is measured with two type K thermocouples, with one positioned at the inlet and the second at the outlet.

The study of the gas-phase dynamics in the WFR allows the quantification of the production rates of different oxidation products and their solubility in the water film (Henri's law constants). At the end of every reaction, the water film can be nebulized to analyze the bulk and the molecular composition of the secondary organic aerosol formed in the aqueous phase (aqSOA) and to quantify its yields. Product solubility and aqSOA yields are parameterized and implemented in global models to quantify the burden of SOA formed in clouds from different precursors.

For a detailed description see:

-

Lamkaddam H, Dommen J, Ranjithkumar A, Gordon H, Wehrle G, Krechmer J, et al.

Large contribution to secondary organic aerosol from isoprene cloud chemistry

Science Advances. 2021; 7(13): eabe2952 (10 pp.). https://doi.org/10.1126/sciadv.abe2952

DORA PSI

PSI mobile atmospheric simulation facilities

Traditional smog chambers and flow reactors are often used to probe model systems, which can be an oversimplification of ambient emissions and conditions. Furthermore, they often lack portability, which make it challenging to bridge the gap between controlled laboratory experiments and real-world emission sources. The mobile smog chamber and mobile flow reactor have been constructed to overcome these limitations: we take these facilities to the emissions. These facilities can be used for elucidating secondary aerosol formation potential under various ambient conditions and for different emission sources such as fossil fuel combustion (from vehicles, aircraft, and shipping), wood burning, as well as other emission sources.

PSI emission facility

In addition to studying secondary organic aerosol formation from specific precursors, the PACs is coupled with PSI emission facility, allowing the characterization of real world emissions and their atmospheric aging with different oxidants (OH, O3 and NO3) and with light. Generated emissions are sampled through heated silco-style lines using one or two Dekati® Diluter DI-1000 systems, which provides a dilution ratio of ten or hundred, respectively. Sampled emissions can be injected into the PSI smog chamber or a stainless steel holding chamber. The latter allows overcoming the limitation of the high emission variability, providing the possibility to obtain an average representative sample of complex emissions, which can be subsequently studied for several hours using the different flow reactors. The facility provides the possibility of measuring the consumption rate of burning fuels and the burning temperature.

Sources generated using this facility include residential wood and coal burning emissions, plastic burning emissions, cow dung burning emissions, open agricultural burning and wildfires, cooking and barbeque emissions and idling car emissions. Furthermore, the mobile smog chamber and OFR were deployed at external emission facilities to study biomass smoke from industrial boilers, vehicular emissions including from passenger cars, mopeds, and heavy duty trucks, jet engines and ship engines.

Transnational Access

The PSI Atmospheric Simulation Chambers and Reactors (PACS) are part of the ATMO-ACCESS program. This program supports researchers in accessing state-of-the-art atmospheric simulation chamber facilities in Europe, including the PACS facilities at PSI. The ATMO-ACCESS program offers opportunities for researchers to bring their instruments and expertise to various simulation chambers for measurement campaigns and instrument testing. Further details on this "Transnational Access" program, including on how to apply for facility access, can be found here.

Publications

More than 80 papers have been published from smog chamber experiments at PSI: see Publication list