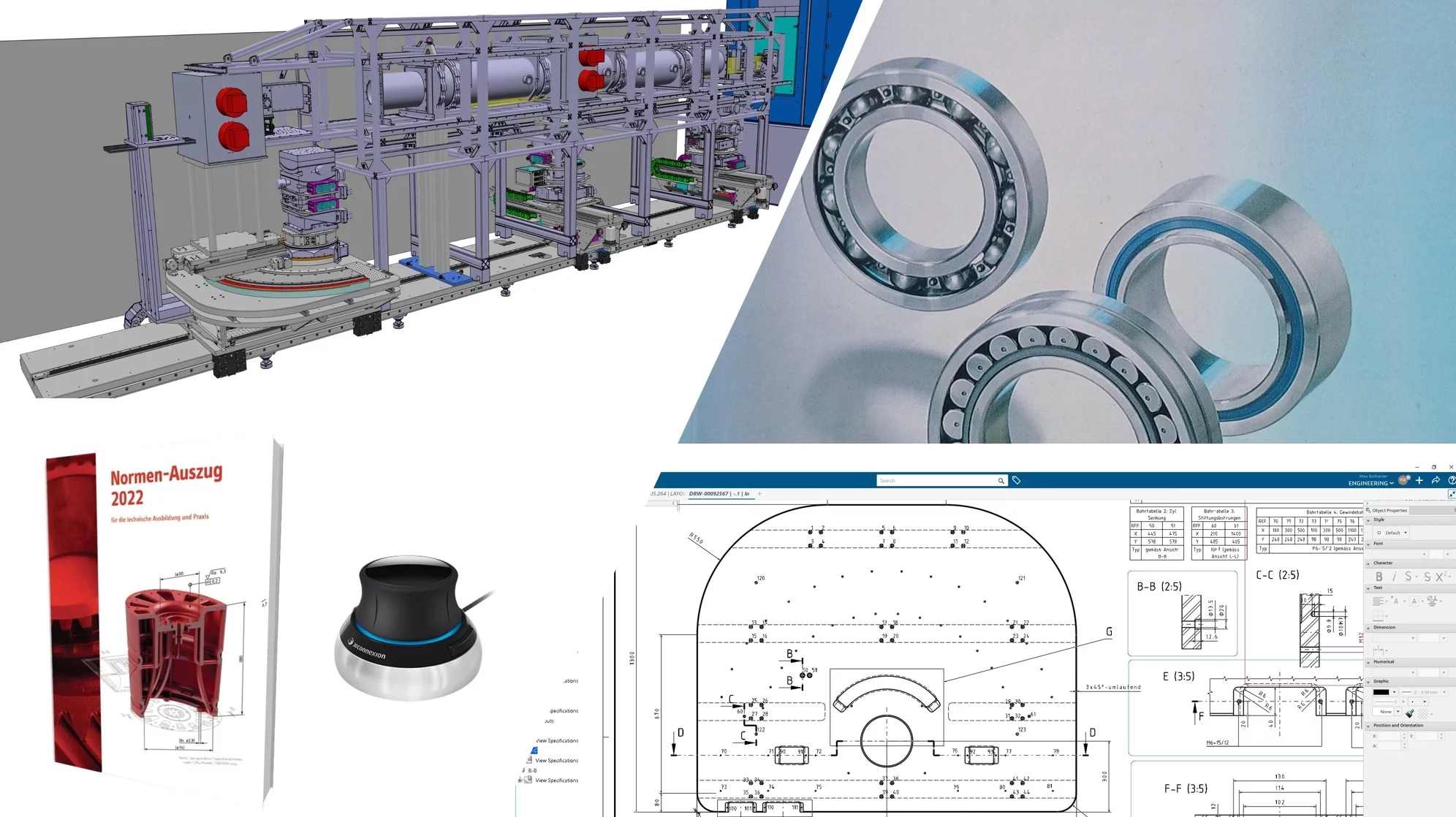

Design

We have a long experience in design of neutron instruments. Along with the scientists we start the projects from early beginning up to the first experiments.

Continuous support and maintenance belongs to our tasks as well as Instrument upgrades or development of new sample equipment.

We also offer project management and are the contact partner for any kind of part manufacturing.

During the years we collected a huge amount of knowledge in different design topics: Neutrons- and muons-instruments, neutron-optics, focusing mechanism, neutron-shielding, gamma-shielding, magnetically-shielding, detector-shielding, unmagnetisable mechanics, vacuum, cryogenic, glass, silicon, ceramic, plastic and concrete.

Calculations

Some of our components and assemblys will be exposed to high magnetic fields, high pressure, vacuum or Cryogenic temperatures.

Calculations with COMSOL Multiphysics® or Ansys help finding suitable solutions for our engineering tasks.

Developments and studies

Next to our engineering activities we are also involved with different developments and studies.

The purpose is to learn about the feasibility of new designs or to gain knowledge about new production techniques.

Production and assembly

Our small production-workshop is located inside the SINQ-building. Since it is in the same hall as the neutron-instruments it allows us to support running experiments fast and very close with the requested items, sample holders or other needs.

This workshop is equipped with standard tool-machines like: Milling, turning and drilling. We also do TIG welding there. Our specialized knowledge refers to fine mechanics, thin lead turning-pieces and casting of neutron absorber-pieces. We also have access to a well-equipped central workshop at PSI.

We also assemble various scientific equipment such as collimators, monochromators, apertures, vacuum flight tubes or positioning devices.

Maintenance and repair

We maintain complete instruments and equipment such as: Positioning systems, focusing mechanism, vacuum systems, choppers or velocity selectors.

If mechanical spare parts for service or repair are not commercially available, we frequently manufacture them ourselves in the workshop.