Lasers can be used to directly structure a wide range of materials, if the right wavelength and power-density is used. Due to the high cost of laser photons, it might be more effective to use a combination of laser structuring and alternative methods (e.g. reactive ion etching). If the target materials is transparent for the selected wavelength, indirect structuring methods (such as laser induced backside wet etching) have to be used.

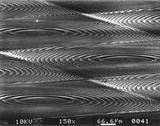

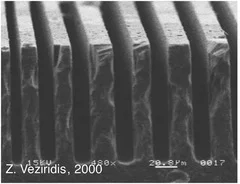

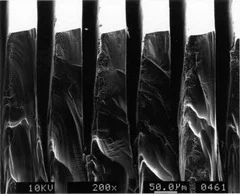

Direct laser ablation: Polymers

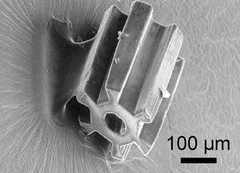

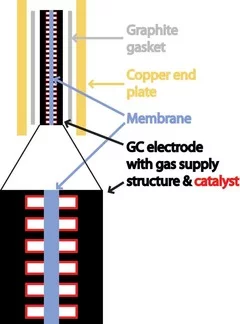

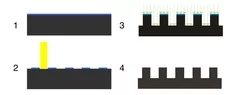

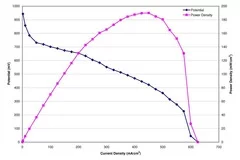

Fabrication of Electrodes for Micro Fuel Cells

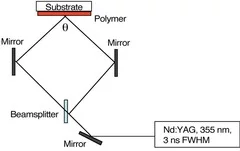

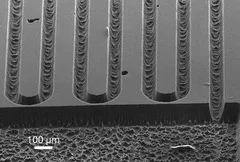

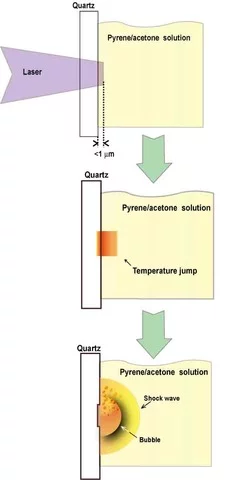

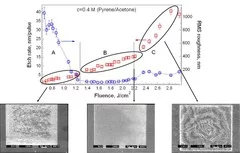

Laser Induced Backside Wet Etching (LIBWE)

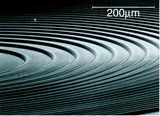

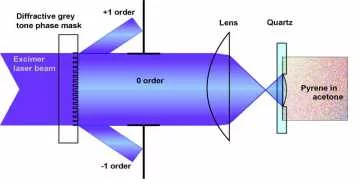

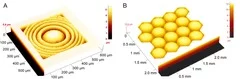

Fabrication of microoptical elements in UV transparent materials by LIBWE and projection of DGTPM

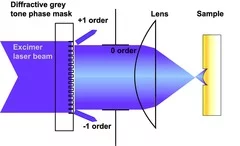

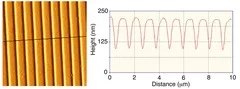

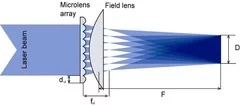

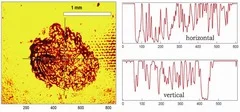

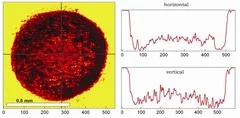

The diffractive gray tone phase masks are used to modulate the laser beam intensity. They are fabricated by e-beam lithography and reactive ion etching. The modulation of the laser light intensity, which is projected onto the sample is obtained by changing the line width in the DGTPM.

The diffractive gray tone phase masks are used to modulate the laser beam intensity. They are fabricated by e-beam lithography and reactive ion etching. The modulation of the laser light intensity, which is projected onto the sample is obtained by changing the line width in the DGTPM.