The Materials Science team operates the Powder Diffraction and the Surface Diffraction stations at the SLS and is active in research utilizing hard x-ray scattering and diffraction for structural and dynamical investigations of crystalline materials.

Surface diffraction

Atoms at or near the surface of a crystalline material in general experience different electrostatic forces than atoms located deeper down in the bulk of the material, primarily because some of the electrons that would, for "bulk" atoms, be involved in forming a bond with neighbouring atoms are now left "dangling" at the surface. They inevitably reconfigure their distribution in order to minimize the surface energy, which leads to the surface atoms rearranging themselves. The physical properties of the surface (defined as the region down to which atomic positions differ "significantly" from bulk values) can therefore be quite distinct from the same material's bulk properties. On the one hand, this can limit the minimum thickness of a material, below which its bulk properties no longer apply, or conversely, the surface of a crystal may have new and unexpected properties that can be exploited in nanostructural design. At the SD station of the Materials Science beamline, we are especially interested in investigating the surface structure of complex metal oxides, in particular the perovskites, as these are known to change their properties radically as a result of subtle structural modifications.

Materials Science Research

In-situ kinetic studies of complex metal-oxide thin film growth

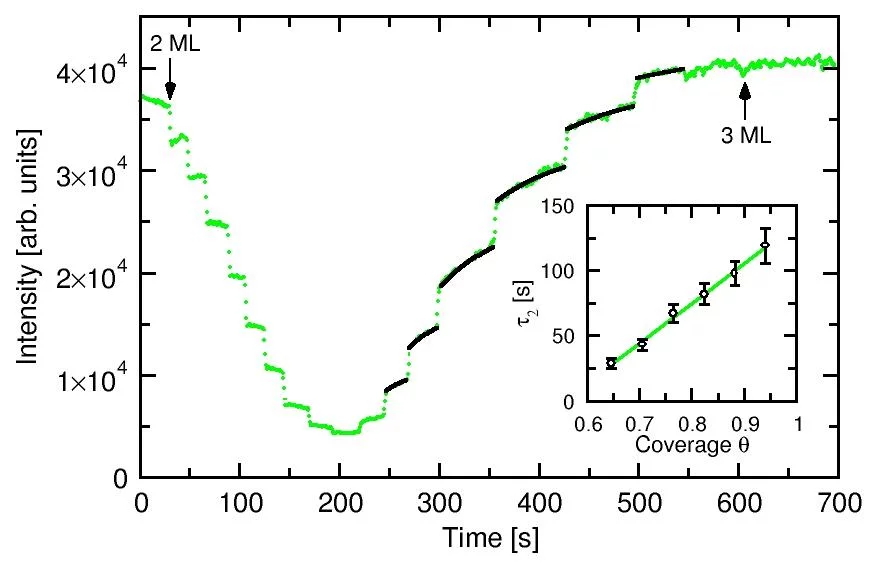

The surface diffusion dynamics of complex metal-oxide thin film growth by pulsed laser deposition was investigated by monitoring the x-ray reflectivity (XRR) at the (0 0 1/2) position on the specular rod. Film growth proceeded by 2-dimensional island coalescence. It was seen that during the first half of any given monolayer (ML) growth, any temporal change in the XRR signal in between laser shots was too fast to be monitored using the available time resolution. After 50% coverage, however, it was observed that the signal relaxed exponentially with a time constant proportional to the amount of coverage above 50%. This behaviour can be explained by small 2-D islands nucleating in the first half of ML-growth, which are then broken up by any energetic PLD particle impinging on top of them. Above 50% coverage, the islnads coalesce, which shuts down the island breakup mechanism, due to the increased mass of material which must be laterally shifted to cause island breakup.

The complex surface structure of strontium titanate

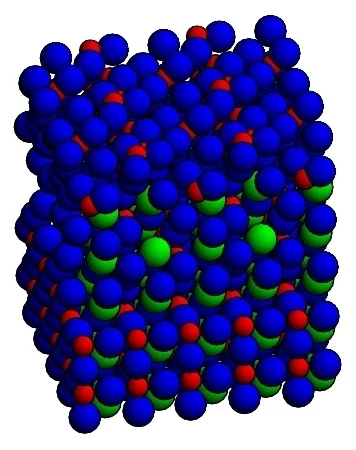

SrTiO3 (STO) is the prototypical substrate type for the thin film growth of perovskites, and as such is widely used by materials scientists and physicists alike. Despite this, little is known or agreed upon regarding its surface structure. A large data set, consisting of over 1800 individual data points, of the surface of STO was recorded using surface x-ray diffraction. It was found that the surface of STO consists of three different structures, which evolve from the common bulk structure. Analysis has shown that these structures and their relative contributions are mediated by the formation of a double surface layer of TiO2, and the rearrangement of the titanium atoms on the uppermost atomic layer. All three structures show significant shifts from the bulk atomic positions down to 3 monolayers, which may have important consequences on unknown surface properties. For example, theoretical studies have suggested that STO may be ferroelectric at the surface, and indeed our own recent results provide circumstantial evidence that regularly sized surface domains of a possibly ferroelectric nature may indeed exist. The above results could only be performed in typical times allocated for beamtime by the implementation of the PILATUS II pixel detector, designed and manufactured at PSI