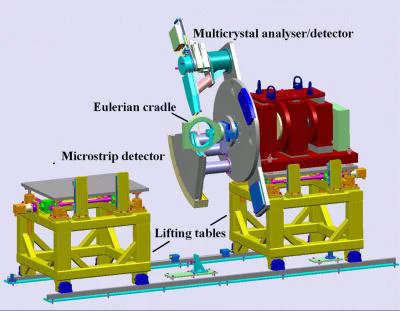

The MS Powder diffractometer is situated in the first experimental hutch of the MS beamline and has three coaxial independent angular degrees of freedom with a mechanical angular accuracy of ± 1 arcsec and a vertical diffraction plane (Fig.1). The central rotation stage (ω-axis) hosts the sample or sample environment. The other two rotation stages carry independent detector systems (see Detectors section for more details):

1. A fivefold Si(111) crystal-analyzer/scintillator detector based on the design invented by Hodeau and co-workers in 1997 that allows parallel detection with a nominal 2o 2θ separation between adjacent channels and a maximum counting rate of the order of 1 MHz

2. A unique solid-state silicon single-photon counting "microstrip detector", called MYTHEN detector. The second generation microstrip detector, MYTHEN II, consists of 30,720 Si-detector elements (50 micron strips, each subtending 4 x 10-3degrees). The total subtended angle is 120o.

The inner stage provides the ω-movement of the sample, which can either be mounted on a spinner (for good statistical averaging), or on a Eulerian cradle, for single-crystal, textured, or strained samples. One outer stage performs the 2θ- movements of 5 high-resolution crystal-analyzer detectors and the other the 2θ-movement of the microstrip detector. These and other aspects are detailed in an overview of the PD station here.

- Spinner for Capillaries

- Spinner for Flat Plates

- Eulerian Cradle

- Janis Cryostat (only capillaries, 4.5-300 K)

- OXFORD Cryojet (90-500 K)

- Heat Gun (300 - 1300 K)

- STOE Furnace (only capillaries, 300 - 1700 K)

- Membrane and screw driven Diamond Anvil Cell (0.5 mm culets, 0.1-20 GPa, for experiments at high pressure please contact well in time Nicola Casati)

- In situ ball mill, own design

- PD hutch webcam

- Support precision table

Simultaneous SAXS-WAXS XRPD experiments can be carried out at the MS-PD Station. A small MYTHEN II unit including only 3 modules (3840 channels) can be placed on a motored support within the powder hutch, from 2 m up to ca. 5 m downstream from the sample, covering 2.2 to 5.5 deg (depending on the distance). Acquisition is then synchronized with the larger MYTHEN II detector encased in a circular sector shaped box centered on the sample position. A transparent window in the large detector box reduces the dead region between the two detectors to practically zero, limited only by the cross section of the primary beam. The setup is under commissioning but accessible to expert users. It is being actively developed, with a planned flight tube for reducing the background signal. Also planned is the use of a Pilatus 2M (available in the detector pool from 2015) in alternative to the small Mythen II unit, for recording 2-D scattering patterns.

- Sample Preparation

Sample preparation is generally rather simple, consisting in filling the appropriate capillaries with the sample. It is generally the responsibility of the users to do this. The same holds of course for special sample containers belonging to user-provided equipment. We provide simple instruments for filling capillaries, including access (on request) to a glove box, and common glass or quartz capillaries of various diameters. Special capillaries - like sapphire capillaries for high temperature - must be brought by the users. Also for more complex preparations - like filling the sample in the DAC - we are endowed with the necessary equipment (microscope, etc.).

- Choice of detector

See this page for general considerations. The appropriate thing is always to discuss your choice with the beamline scientists.

- Choice of working photon energy

The MYTHEN II has inbuilt capability to discard photons below a given threshold. This enables one to avoid the nasty fluorescence background. To be effective, the threshold must be set at least 3 keV above the energy of the photons to be discarded (i.e. the highest excited emission line), and, in order not to lose efficiency on the elastically scattered photons, at least 3 keV below the beam energy. Therefore, the beam energy sometimes must be chosen with this in mind, given the sample composition. Absorption lines can be evaluated e.g. at this NIST webpage and emission lines from this document.

- 2008 PSI-AIC-SSCr International School on "Structural Determination from Powder Diffraction Data

- 2010 PSI-AIC-SSCr International School on "Diffraction at the Nanoscale: Nanoscrystals, Defective & Amorphous Materials"

- 2012 PSI Powder Diffraction School on "Structure and Microstructure"

- 2014 PSI Powder Diffraction School on "Modern synchrotron methods"

- 2016 PSI Powder Diffraction School on "Modern synchrotron methods"

- SR-XRPD applied to nano- and non- crystallyne materials: Total Scattering methods

Total scattering methods are relatively young. They avoid the traditional Bragg method, that assumes a basically periodic structure. In fact, the Bragg method is a very useful simplification when considering diffraction from a basically periodic structure, but diffraction can be evaluated without this assumption. A brief idea of how to do it is given in this document: Diffraction Basics

Total Scattering methods have been mostly used in connection with powder diffraction. It is evident that the smaller data volume (being a powder diffraction pattern fundamentally one-dimensional) is a crucial advantage in this case. Nevertheless, rare single crystal applications have been successful (see e.g. P. Schaub, T. Weber, W. Steurer, J. Appl. Cryst. (2011) 44, 134-149). However, here we will focus on Total Scattering methods for powder diffraction.

Total Scattering implies considering the whole diffraction pattern as a source of information. Two methods of extracting information have been devised. The first method (also historically) - the PDF (Pair Distribution Function) method - relies on a specialized Fourier transform applied directly on the data. This puts strong constraints on the data quality. Firstly, in order to minimize truncation errors, powder pattern must extend to high momentum transfer - and this in turn means measuring also at high angles with high statistics and using short wavelengths (high energies). Furthermore, all sources of background have to be separately measured (always with high momentum transfer and high statistics) and thereafter subtracted from the data. The subtraction process is not trivial when absorption must be considered. Moreover, the density and chemical composition of the sample must be known. The up side is that many interatomic distances between the atoms constituting the sample can be directly observed, especially in the range below a few nanometers where there is not much overlap. The interatomic distances are very illuminating when trying to solve or to see a change within the atomic structure.

A second method - the DFA (Debye Function Analysis) method - is much more friendly from the experimental point of view, while a bit more computationally intensive. It relies on modelling of the atomic structure - via the evaluation and transform of the interatomic distances - in order to try to match the experimental data. A high maximum transferred momentum is not important in this case; it is enough that the main scattering features be included in the experimental range. Background subtraction is still desirable, although the pattern matching algorithm can include some heuristic background function (usually Chebyshev polynomials of small-medium degree) to take into account some weakly varying background.

For a short explaination of how PDF and DFA work, see the attached PDF vs DFA. Software for evaluating the PDF is freely available on the net (see e.g. PDFGETX2 and DISCUS). As well, the program suite Debussy dedicated to refining powder patterns using the DFA, coauthored by Antonio Cervellino and A. Guagliardi (Dip.to di Scienze Chimiche ed Ambientali, Insubria University, 22100 Como, Italy and Istituto di Cristallografia, CNR, 70126 Bari, Italy), is freely available under GPL license (download binaries for Mac OSX and Linux, source code in f95). Debussy - as decribed in this paper - is especially valuable for extracting information relevant to mixtures of nanocrystals containing different phases and where each phase may have a complex size/shape distribution. It can also refine some global parameters (e.g. phase fractions, background), some parameters for each phase (size/shape distribution parameters) and also parameters that depend on the phase and have also a dependence on the size/shape of the individual crystallite (site occupancy, thermal vibration amplitude, lattice expansion).

- Modelling of MYTHEN Instrumental Resolution Function

The line profile contribution coming from the sample extension for the case of a spinning glass capillary - mounted sample in Debye-Scherrer geometry and with a detector without angular analyzer has been thoroughly investigated and modeled analytically and numerically. For more information see this paper.

N. Casati, reviewed on Sep 8, 2016