The alkali-silica reaction (ASR) is a severe deterioration mechanism, which can severely limit the service life of outdoor concrete structures such as dams and bridges. In the ASR, the alkaline pore solution of concrete reacts with silica present in rocks used as concrete aggregates. With ASR, the basic ingredients in the concrete are actually the problem: cement – the main component of concrete – contains alkali metals such as sodium and potassium. Any moisture infiltrating the concrete – for example stemming from rainwater – dissolves these alkali metals, leading to an alkaline solution. The second main ingredients in concrete are sand and gravel, which in turn are composed of minerals, such as quartz or feldspar. The interaction of the latter minerals with alkaline solution triggers the ASR and results in the formation of the ASR product. The latter is able to accumulate water and to swell, consequently generating stress and cracks. The cracks are initially only tiny and invisible to the naked eye, however, over the course of three or four decades, the cracks widen significantly and eventually jeopardise the durability of the entire concrete structure. As the reaction proceeds very slowly, the first damages are usually observed only after decades after the concrete structures have been built. Substantial damages have been observed worldwide. In Switzerland, several hundreds of structures, including bridges and dams, are affected, causing substantial costs due to repair or replacement. Although the first cases of ASR were reported in the 1940's, to date scientific understanding of the process knowledge is still poor.

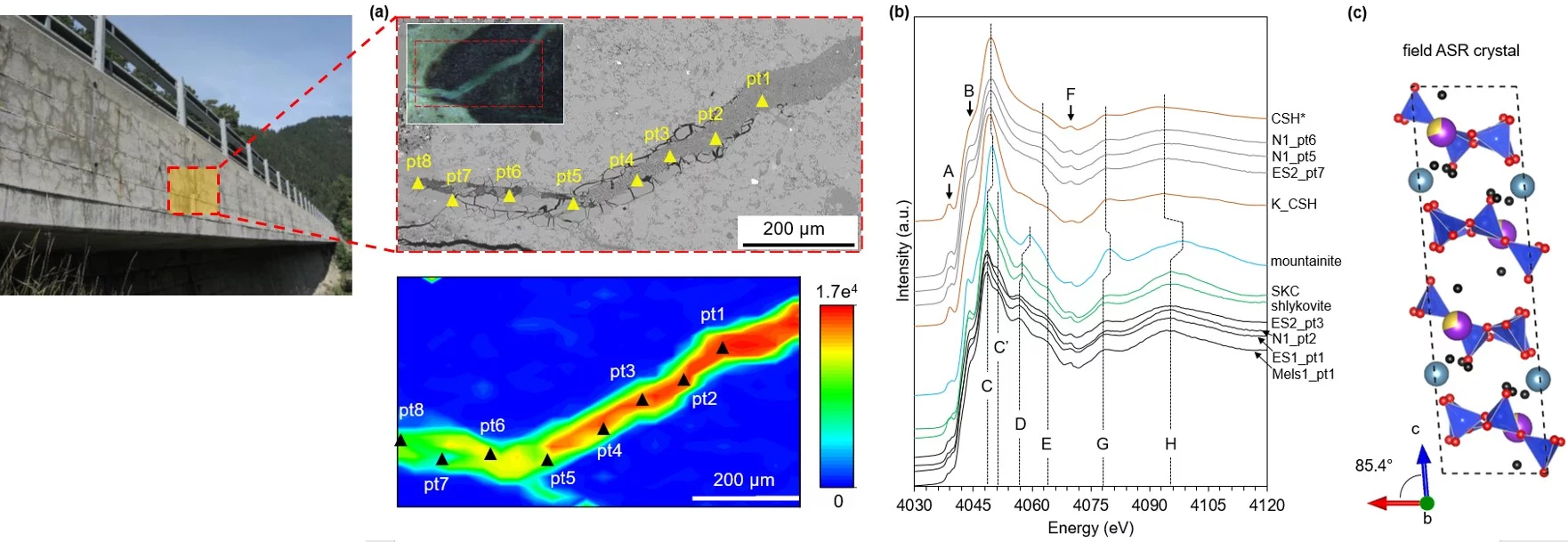

Here we explored the crystallinity and structure of the ASR product in the veins of an in situ altered aggregate grain of an ASR-affected bridge with micro-scale resolution. X-ray absorption micro-spectroscopy at the PHOENIX beamline of the Swiss Light Source (SLS) provided insight into the crystallinity and structure of ASR products. Concrete samples with ASR damage demonstrate a universal micro-morphology of reaction product veins running from inside the aggregate to the cementitious paste, as shown by the SEM image (Fig. 1a). The product inside the aggregate is often crystalline with nano-platy morphology, while the product in the cementitious paste is often amorphous. Ca, K and Na K-edge XANES spectra were collected at spots within both crystalline and amorphous regions of the product vein (Fig. 1b), according to the florescence map of the microstructure. Examples of Ca K-edge XANES are displayed. They were compared with reference phases. The results indicate that the crystalline ASR products exhibit an identical chemical environment, despite their distinct sources and exposure conditions. Similarly, the amorphous ASR products from different field specimens are also identical. Furthermore, the crystalline ASR products resemble the structure of shlykovite, which is a layer silicate with Ca layers between silicate sheets and K/Na imbedded within the sheets (Fig. 1c). The amorphous ASR products highly resemble the structure of C-S-H (calcium silicate hydrate) phases, although they seem to have different nano-morphology. For the first time we confirm the molecular configuration of the ASR products, and establish a linkage between them and the lab-synthesized ASR samples. This improved understanding of the ASR structure and crystallinity is essential for studying the thermodynamic and kinetic aspects of the ASR product formation under various boundary conditions. It paves the way to mitigation and management of affected structures and to develop repair strategies.

Contact

Prof. Dr. Guoqing Geng

Department of Civil and Environmental Engineering,

National University of Singapore

Telephone: +65 6601 6197

E-mail: ceegg@nus.edu.sg

Dr. Rainer Dähn

Laboratory for Waste Management

Paul Scherrer Institut

Telephon: +41 56 310 2175

E-mail: rainer.daehn@psi.ch

Dr. Erich Wieland

Laboratory for Waste Management

Paul Scherrer Institut

Telephone: +41 56 310 2291

E-mail: erich.wieland@psi.ch

Dr. Thomas Huthwelker

Swiss Light Source

Paul Scherrer Institut

Telephone: +41 56 310 5314

E-mail: thomas.huthwelker@psi.ch

Original Publication

Atomistic structure of alkali-silica reaction products refined from X-ray diffraction and micro X-ray absorption data

G. Geng, Z.L. Shi, C. Borca, T. Huthwelker, K. Glazyrin, I.V. Pekov, S. Churakov, B. Lothenbach, R. Dähn, E. Wieland

Cement and Concrete Research, 2020, 129, 105958

DOI: 10.1016/j.cemconres.2019.105958