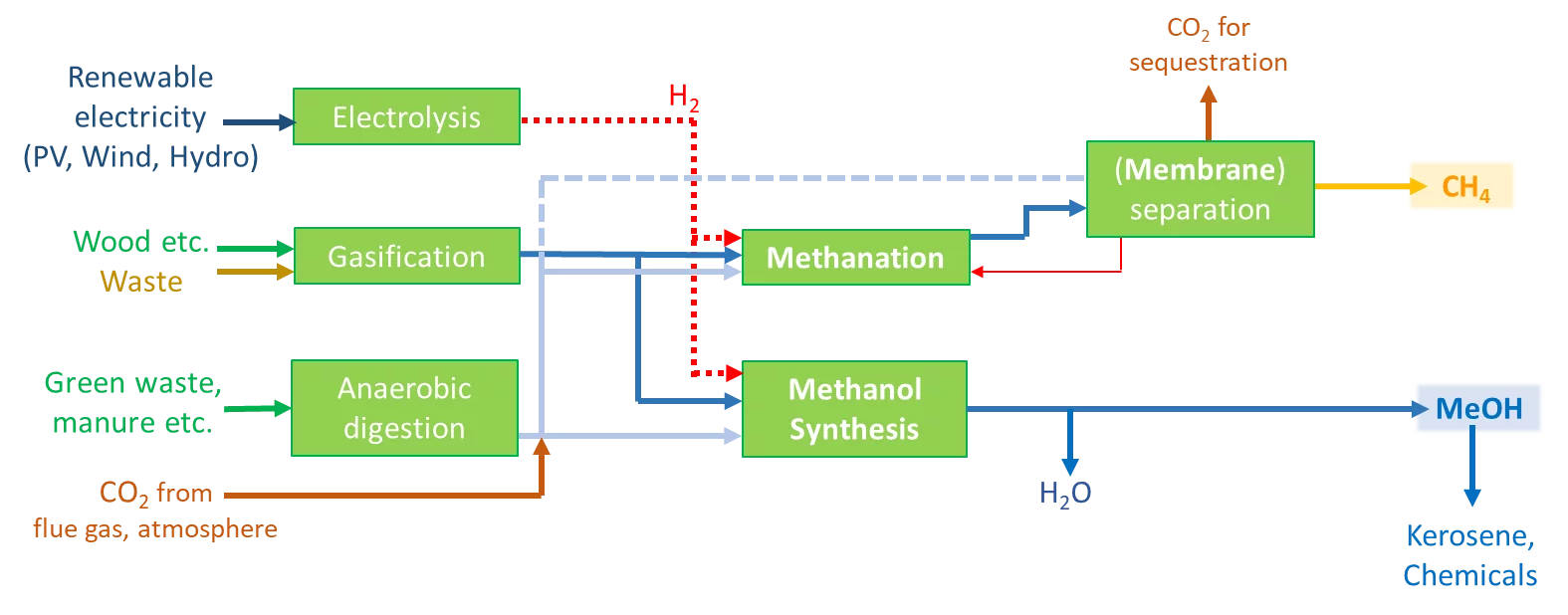

Renewable methane is considered to be a versatile energy carrier which can be used efficiently in different sectors, e.g. for industrial high temperature heat, for combined heat and electricity production (CHP) and in liquified form as fuel for long-distance transport and ships. Moreover, the already existing natural gas grid allows both energy storage and distribution, and thereby complements the electricity grid. Therefore, the synthesis of methane from renewable sources (also referred to as Renewable Natural Gas, Bio-SNG or bio-methane) is an important research focus. Besides conversion of producer gas from wood gasification, methanation of hydrogen from renewable electricity and from gas streams containing carbon oxides (Power-to-Gas, using biogas or CO2 from flue gas) is also investigated.

The central process step, methanation in a catalytic fluidised bed reactor, is studied with respect to fluid dynamic phenomena and the kinetics of the involved chemical reactions. The detailed understanding of the interaction between chemistry and heat/mass transfer allows process optimization for any of the mentioned applications and safe scale-up.

Experimental determination of kinetic parameters at the laboratory scale (Technical Readiness Level: TRL 2-3) is combined with long duration tests (TRL 5) and pilot scale investigations (TRL 6) to obtain a validated rate-based model of the methanation reactor. This reactor model is integrated in simulations of complete process chains to determine optimal process concepts with respect to energy efficiency and economics.

Pilot scale experiments, the validated model and the collaboration within the European Union project HyFuelUp to build a 500 kW methanation plant support the transfer of the knowhow to our industrial partner, the Swiss SME AlphaSYNT GmbH.

Recently, research started to use the acquired knowhow for the development of an efficient small scale methanol synthesis with continuous addition and removal of sorbents.

These activities contribute to the Energy System Integration platform at PSI (ESI).

(Field) campaigns

- Use of the TRL 6 pilot scale plant GanyMeth (>200 kW) to support the scale-up of the technology for a demonstration plant (500 kW) in Portugal within the European Union project HyFuelUp (https://hyfuelup.eu/)

- Successful long duration test at 10 kW scale (container based demo plant COSYMA at TRL 5) converting raw biogas from the 6 MW biogas plant in Zürich Werdhölzli in collaboration with energie360°. More than 1100 hours of stable operation without catalyst deactivation and with only very little catalyst attrition (spring/summer 2017).

Watt d’Or 2018 awarded by the Swiss Federal Office for Energy for the project team “Direct Methanation of Biogas” - Supporting scale-up of the wood-to-SNG process to 1 MWSNG scale within the EU-project Bio-SNG and commissioning of the Pilot & Demonstration Unit, several measurement campaigns (2006-2009).

Watt d’Or 2009 awarded by the Swiss Federal Office for Energy and Schweighofer Prize 2009 for the project team “Methane from Wood” - Successful long duration test at 10 kW scale (Container based demo plant COSYMA at TRL 5) converting producer gas from the commercial wood gasifier in Güssing/Austria to Synthetic Natural gas (SNG). More than 1000h of stable operation without catalyst deactivation (spring/summer 2007).

Key findings

- Methanation, gas cleaning and gas upgrading are the key technology steps to store surplus electricity (Power-to-Gas) and biomass in the natural gas grid for later use in mobility or by combined heat and power production

- Catalytic fluidised bed methanation is robust and allows the conversion of feed gas from all pathways including biogas, CO2/H2 mixtures and producer gas from gasification/pyrolysis containing significant amounts of olefins and aromatics, as shown by several long duration tests

- Thermo-economic analyses showed that the flexibility of fluidised bed methanation allows simplifications in the process chain, especially with respect to gas cleaning, and therefore has significant advantages over competing technologies

- Extended experience in research of process fundamentals, but also in real applications and scale-up including pilot-scale supports better understanding of the interactions between chemical reactions and hydrodynamic phenomena such as mass and heat transfer in the reactors

- The kinetics of the main reactions (methanation and water gas shift) and of the mechanisms of hydrogenation/hydrogenolysis of ethylene could be determined.

- By means of optical sensors, pressure fluctuation measurements and X-ray tomography (in collaboration with TU Delft), detailed knowhow on the hydrodynamic phenomena in fluidised beds were obtained

- The results from the kinetic and hydrodynamic studies are incorporated into a rate based reactor model that will be validated by experiments at pilot scale

Funding

SERI/European Union, SCCER Biosweet (Innosuisse), Energy System Integration platform (ESI), Swiss Federal Office for Energy (SFOE), Swiss National Science Foundation (SNSF), Competence Center for Energy and Mobility (CCEM), swisselectric research, Swiss Gas Association (FOGA), energie360°

Publications

Book and Book chapters

T.J. Schildhauer, F. Schillinger, Reaktoren für Fluid-Feststoff-Reaktionen: Wirbelschichtreaktoren. In: Handbuch Chemische Reaktoren, W. Reschetilowski (Ed.), Springer New York (2019)

T.J. Schildhauer

Biosynthetic Natural Gas (Bio-SNG). In: Meyers R. (eds) Encyclopedia of Sustainability Science and Technology. Springer, New York, NY (2018)

T.J. Schildhauer, S.M.A. Biollaz (Eds.)

Synthetic Natural Gas from Coal, Dry Biomass, and Power-to-Gas Applications

Wiley & Sons, New York, ISBN 9781118541814 (2016)

S. Heyne1, M Seemann1, T.J. Schildhauer, Coal and Biomass Gasification for SNG Production, in Synthetic Natural Gas from Coal, Dry Biomass, and Power-to-Gas Applications, T.J. Schildhauer, S.M.A. Biollaz (Eds.), Wiley & Sons, New York, 5-40 (2016)

1 Chalmers University, Gothenburg, Sweden

T.J. Schildhauer, Methanation for SNG production – Chemical reaction engineering aspects, in Synthetic Natural Gas from Coal, Dry Biomass, and Power-to-Gas Applications, T.J. Schildhauer, S.M.A. Biollaz (Eds.), Wiley & Sons, New York, 77-159 (2016)

T.J. Schildhauer, S.M.A. Biollaz, Fluidised bed methanation for SNG production – process development at the Paul-Scherrer Institut, in Synthetic Natural Gas from Coal, Dry Biomass, and Power-to-Gas Applications, T.J. Schildhauer, S.M.A. Biollaz (Eds.), Wiley & Sons, New York, 221-229 (2016)

C.F.J. König, M. Nachtegaal, T.J. Schildhauer, Integrated desulfurization and methanation concepts for SNG production, in Synthetic Natural Gas from Coal, Dry Biomass, and Power-to-Gas Applications, T.J. Schildhauer, S.M.A. Biollaz (Eds.), Wiley & Sons, New York, 293-306 (2016)

M. Rüdisüli, T.J. Schildhauer, S.M.A. Biollaz, J.R. van Ommen, Measurement, monitoring and control of fluidized bed combustion and gasification, chapter in F. Scala (Ed.), Fluidized bed technologies for near-zero emission combustion and gasification, Woodhead (2013)

Completed PhD

- Philipp Riechmann, Cross-verified independent measurements of correlated bubble property distributions as part of the scale-up of a catalytic bubbling fluidized bed reactor (Thèse EPF Lausanne n° 9873, 2018-2022)

- Andreas Gantenbein, Flexibilisation of Biogas-based Power-to-Gas Processes: A Techno-economic and Experimental Assessment (Thèse EPF Lausanne n° 10032, 2018-2022

- J. Witte, Experimental and modelling study of methanation reactors for production of SNG in Power-to-Gas applications (Diss. ETH Zürich No. 25345, 2014 – 2018)

- F. Schillinger, Hydrodynamic studies in pilot scale fluidised bed reactors (Diss. ETH Zürich No. 25346, 2014 – 2018)

- V. Tschedanoff, Predicting the complex coupling of chemistry and hydrodynamics in fluidised bed methanation reactors for SNG-production from wood (Diss. ETH Zürich No. 23869, 2016)

- S. Maurer, Hydrodynamic characterisation and scale-up of bubbling fluidised beds for catalytic conversion (Diss. ETH Zürich No. 22722, 2015)

- J. Zarfl, Entwicklung und Verwendung von DRIFTS Methoden für die Charakterisierung und Verbesserung von Katalysatoren in Wirbelschicht-Reaktoren (ETH Zürich No. 22183, 2015, in collaboration with CPE group of BCL)

- S. Teske, Methanation in the B-IGFC process chain (Thèse EPF Lausanne n° 6302, 2014)

- M. Rüdisüli, Synthetic natural gas by pressurized methanation of producer gas from biomass gasification (Diss. ETH Zürich No. 20209, 2012)

- J. Kopyscinski, Production of synthetic natural gas in a fluidised bed reactor - Understanding the hydrodynamic, mass transfer and kinetic effects, (Diss. ETH Zürich No. 18800, 2009)

- M.C. Seemann, Methanation of biosyngas in a fluidized bed reactor (Diss. ETH Zürich No. 16754, 2006)