POLDI is a so-called neutron Time-Of-Flight (TOF) diffractometer. Thermal and cold neutrons have such a low velocity that their energy can be determined by the accurate measurement of the time needed to travel a given distance. This allows using the full neutron energy spectrum combined with a neutron detector at a fixed diffraction angle.

For strain scanning experiments TOF diffractometers have important advantages compared to constant wave length diffractometers. However, SINQ is a continuous neutron source so therefore a chopper is needed to create a pulsed neutron beam. Conventional TOF-diffractometers usually have choppers with a low duty cycle because of the restriction that fast neutrons from a given neutron pulse may not catch up with slow neutrons from previous pulses (pulse overlap). In this case a constant wavelength diffractometers would provide better performance.

POLDI concept

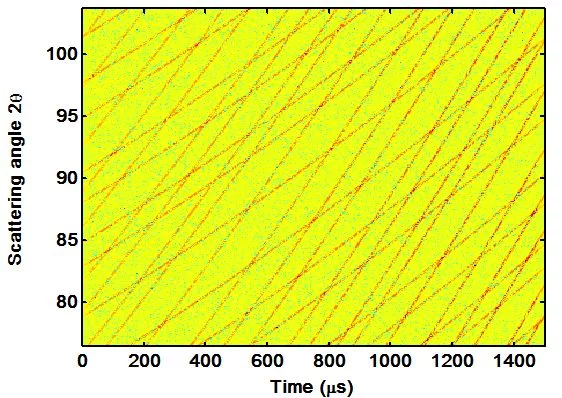

The principal idea of the POLDI concept is that the restriction that fast neutrons may not catch up slower neutrons of previous pulses is dropped and that the angular dependence of the TOF is used as additional parameter for data analysis. The arrival time of the neutrons are measured in dependence of the scattering angle. In a plot of intensity vs. arrival time and scattering angle each Bragg reflection is represented by a Bragg line (see figure 1).

The slopes of these Bragg lines are given by:

$\frac{\mathrm{d}t}{\mathrm{d}\theta} = t_{flight} \cdot \left(\cot\theta + \frac{1}{s_{tot}}\frac{\mathrm{d}s_{tot}}{\mathrm{d}\theta}\right)$

Therefore, the slope of the Bragg lines alone give information about the flight time of the neutrons. This information allows to trace the slit of the chopper the neutron came from. Since the exact time when this slit opened the neutron beam and the arrival time of the neutron at the detector is known it is now possible to determine the exact time-of-flight of the neutrons, and therefore also the lattice spacing, with the same accuracy as with a conventional time-of-flight diffractometer.

Main advantages of the POLDI concept

The quantities intensity and resolution are decoupled:

- The intensity is given by the duty cycle of the chopper but the resolution by the chopper speed.

- High intensity and good resolution can be achieved simultaneous.