The INTEGER research program (https://www.psi.ch/lnm/materials-ageing-and-structural-integrity) of the Laboratory for Nuclear Materials (https://www.psi.ch/lnm/about-lnm) is dealing with the material ageing in pressure boundary components and reactor internals of light water reactors and its impact on integrity, safety and lifetime (extension). During service, these components are subjected to a variety of different potential ageing and degradation mechanism that can lead to the formation and growth of cracks (e.g., stress corrosion cracking, fatigue) and/or a reduction of the material toughness/ductility and resistance against catastrophic mechanical failure (e.g., irradiation embrittlement, thermal ageing).

In this context, the EMF in combination with other facilities (https://www.psi.ch/lnm/experimental-facilities) plays an important role for

- the experimental characterization of critical ageing mechanism for the safe long-term operation (e.g., micro-mechanical & -structural characterization of radiation damage) and the validation of their potential mitigation actions (e.g., SCC mitigation by OLNC)

- the identification of the underlying degradation mechanism (e.g., micro-plastic damage evolution in fatigue) that is essential for the mechanistic modeling of the damage evolution and reliable lifetime prediction.

Micro-mechanical & -structural characterization of radiation damage

The radiation embrittlement of the reactor pressure vessel and reactor internals or the irradiation-assisted stress corrosion cracking of reactor internals are critical for safety and lifetime of nuclear reactors. The targeted and efficient sub-size sample preparation of radioactive materials for micro-chemical, -microstructural, & -mechanical characterizations at specific locations (e.g, grain and phase boundaries, oxide film-metal or inclusion-metal interfaces, crack-tips, fracture surface, ...) is a cruical element for the identification of the underlying damage mechanism.

FIB for micro-mechanical testing:

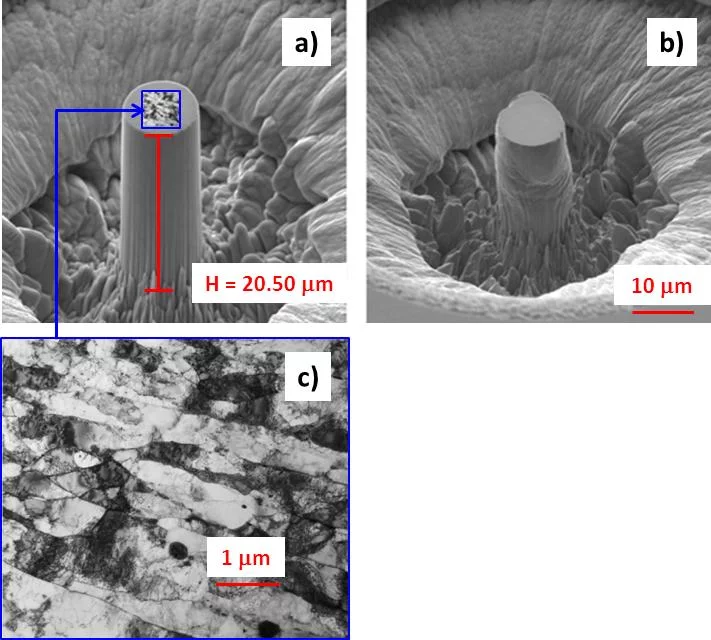

As a general rule, the number irradiated specimens to investiagte the mechanical properties following a given irradiation condition is small and limited by the available irradiation volume. So it is highly desirable to determine those mechanical properties with small specimens to increase the number data from a given amount of materials. In addition, testing small specimens has the advantage of decreasing the residual dose rate and radiological exposition to personnel, and offers the possibitliy to assess the properties at a local scale. Testing micro-pillars in compression (Fig. 1) has become a common technique to investigate mechanical properties of a variety of materials, which we used to follow the evolution of the plastic flow properties with neutron-irradiation. Micro-pillars of the high-chromium tempered martensitic steel Eurofer97 were prepared by FIBing and deformed with a G200 nanoindenter equipped with a flat indenter. The deformation curves were supplemented by finite element simulations to determine the true stress/strain curve by applying a so-called inverse method. [1]

Reference:

[1] N. Ilchuk, P. Spätig, H.-P. Seifert, "Analytical determination of the constitutive behavior from micro-pillar testing, Application to a tempered martensitic steel." AIP Advances 4, (2014) 047126.

FIB for TEM lamella preparation:

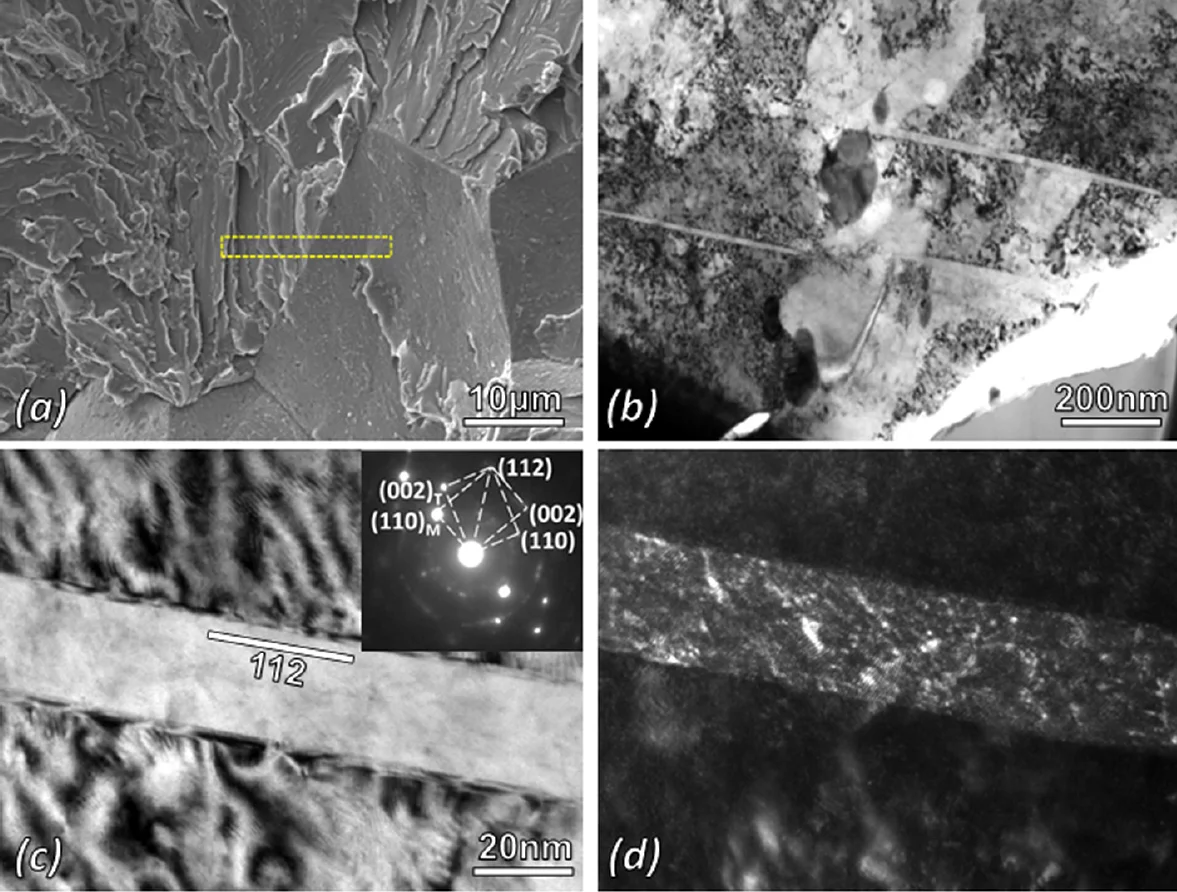

FIBing is also extensively used to prepare electron transparent thin lamellas with a thickness from 120 to 150 nm. As another example we show in Fig 2 how the FIB was used as an innovative technique to perform microstructural characterization under the fracture surfaces of Eurofer97 tensile specimens irradiated at high dose in the Swiss spallation neutron source SINQ at PSI. In Fig 2, we show: (a) the area on fracture surface of the specimen where a TEM lamella extracted; (b) an edge-on view of deformation twins in the lamella; (c) and (d) a closed view of a twin in bright and dark field imaging conditions. [2]

Reference:

[2] K. Wang, Y. Dai, P. Spätig, "Microstructure and fracture behavior of F82H steel under different irradiation and tensile test conditions", Journal of Nuclear Materials 468 (2016) pp. 246-254.

SCC mitigation by OLNC:

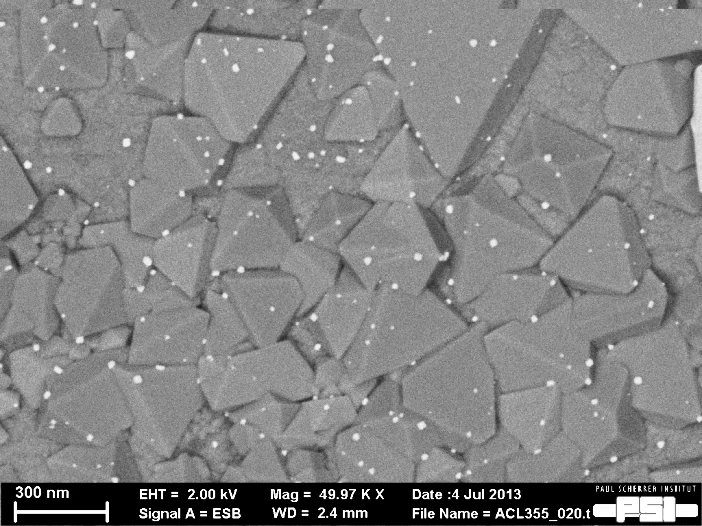

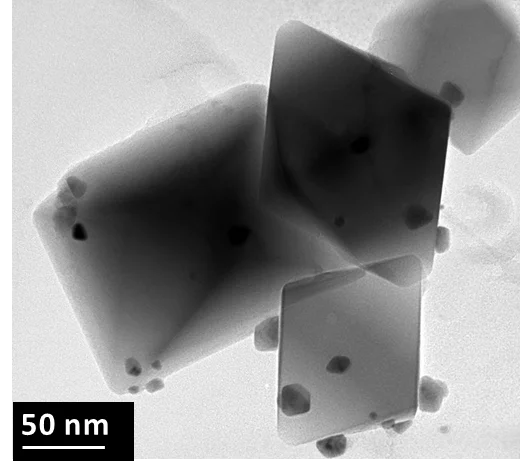

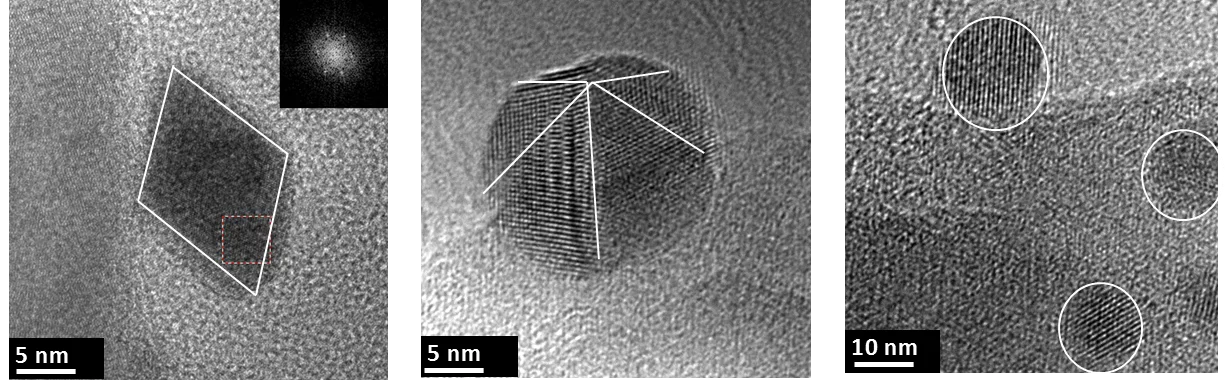

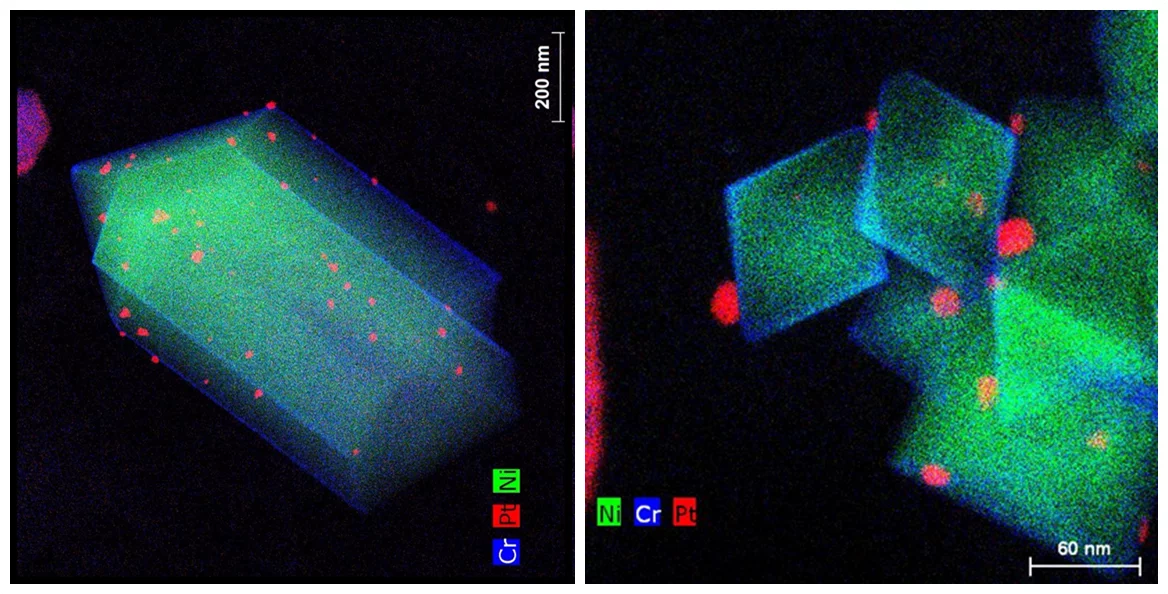

Stress corrosion cracking in reactor internals and recirculation pipes is one of the major degradation issues in boiling water reactors (BWRs). On-Line NobleChemTM is a technology for mitigating this cracking by efficient reduction of the electrochemical corrosion potential, without the negative side-effects of classical hydrogen water chemistry. To achieve this reduction, platinum is injected into the feed water during power operation and is claimed to deposit as metallic nanoparticles on all water-wetted surfaces, and staying electrocatalytic over long periods. To validate and improve the efficiency of this mitigation technology, the deposition and distribution behaviour of platinum in BWRs is studied at PSI. The main objective of this project is the detailed investigation of the distribution, size and shape of the Pt particles and its local concentration on surfaces of primary pressure boundary materials in simulated and real BWR environments. High-resolution studies of the platinum particles by electron microscopy (FEG-SEM and TEM, Figs 3 & 4) is one of the key techniques to get new insights and to better understand the catalytic behaviour and the bonding of the Pt particles to the oxide film. The morphology and microstructure & chemistry of single Pt nanoparticles is studied by TEM/HRTEM and STEM techniques, including EDS (Figs 5 & 6). TEM specimens are prepared by using a replica technique, allowing the removal of Pt particles together with some of oxide crystals from the outer part of the oxide layer. [3-9]

References:

[3] S. Ritter, P.V. Grundler, L. Veleva, and W. Kaufmann, "Effect of Pt Pre-Treatment of Fresh Stainless Steel Surfaces on the 60co Build-up During BWR Power Operation", in: Nuclear Plant Chemistry (NPC) Conference, Paper No. 104 (CD-ROM), Brighton, UK, October 2-7, 2016.

[4] H.F. Gu, B. Niceno, P.V. Grundler, M. Sharabi, L. Veleva, and S. Ritter, "Computational Study of Platinum Nanoparticle Deposition on the Surfaces of Crevices", Nuclear Engineering and Design, 2016, 304, pp. 84-99.

[5] P.V. Grundler, S. Ritter, L. Veleva, L. Oliver, B. Helmerson, S. Allner, and G. Ledergerber, "Influence of Pt Deposition on the Behaviour of Zircaloy Cladding under Boiling Conditions in Simulated BWR Environment ", in: Nuclear Plant Chemistry (NPC) Conference, Paper No. 30, Brighton, UK, October 2-7, 2016.

[6] S. Ritter, P.V. Grundler, L. Veleva, and G. Ledergerber, "Platinum Deposition Behaviour on Stainless Steel Surfaces in a Boiling Water Reactor Plant", in: EUROCORR 2015, European Federation of Corrosion, Paper No. 870 (CD-ROM), Graz, Austria, September 6-10, 2015.

[7] P.V. Grundler, L. Veleva, A. Ramar, and S. Ritter, "Effect of Flow Conditions on the Deposition of Platinum Nanoparticles on Stainless Steel Surfaces", Corrosion, 2015, 71(1), pp. 101-113.

[8] P.V. Grundler, L. Veleva, and S. Ritter, "Pt: Key to Improved SCC Mitigation", Nuclear Engineering International, 2014, 59(725), pp. 33-35.

[9] P.V. Grundler and S. Ritter, "Noble Metal Chemical Addition for Mitigation of Stress Corrosion Cracking: Theoretical Insights and Applications", PowerPlant Chemistry, 2014, 16(2), pp. 76-93.

-plastic damage evolution in fatigue:

Fatigue is an important ageing mechanism in light-water reactors and has to be carefully evaluated and monitored, in particular with increasing plant age in the context of safe long-term operation or anticipated increasing load following due to the "Energiewende". In the last decades, several thermo-mechanical fatigue (TMF) cracking incidents have occurred in fatigue-desigend pressure-boundary components, which were caused by (non-anticipated) complex thermal-hydraulic phenomena (turbulent mixing, thermal stratification and striping, etc.), that were not included in the original design and are only partially covered by current fatigue design and evaluation codes. Several of these incidents involved leakage of primary water inside the containment and challenged the integrity of LWRs, fortunately without the release of radioactivity outside the containment. Some of these incidents were potentially aggravated by corrosive high-temperature water effects. Within various projects, we are currently investigating the environmentally-assisted fatigue (EAF) initiation process in high-temperature water and TMF initiation process in air under multi-axial loading conditions. The underlying initiation mechanisms and local micro-plasticity evolution during fatigue are studied by advanced characterization techniques (TEM, EBSD/SEM, DIC and FIB), from which the gathered insights will be used to improve, calibrate and validate the corresponding mechanistic fatigue models. [10-14] Investigation of dislocation microstructures of fatigue

specimens:

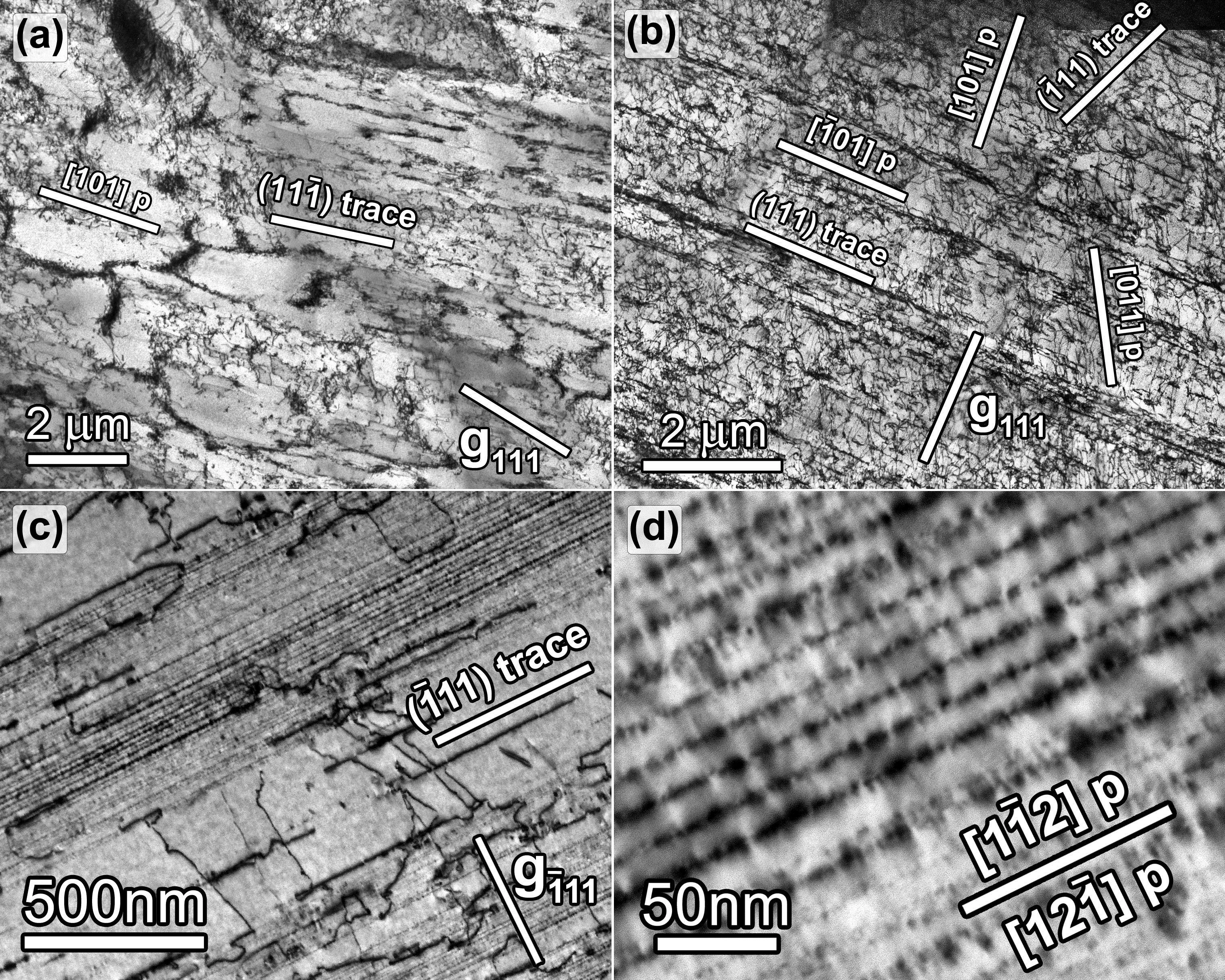

To better understand the effect of mean stress on fatigue life of 316L austenitic stainless steel at the temperature of 288°C in air and in high-temperature water, the corresponding cyclic hardeing/softening response in stress- and strain-controlled fatigue experiments at various stress/strain amplitudes and mean stress levels is correlated with the evolution of disloctaion structures revealed by TEM investigations. It was found that there are no significant differences in dislocation structures and arrangements between samples tested in air and water environment. At high stress amplitude (190 MPa), the observed dislocation structures are in a good correlation with findings in literature. Several slip systems are activated leading along with cross-slip mechanisms to vein-like structures and subsequently to onset of wall/channel arrangements formation. Material shows cyclic softening response during this period. Cyclic plastic strain is localized into persistent slip bands (PSBs) present in the form of ladder-like structure (Fig 7a). The application of a mean stress of 50 MPa at high stress amplitude results in a completely different dislocation arrangement where no spatial 3D low energy dislocation structures are found (Fig 7b). Presence of corduroy structure was also observed and put in relation to secondary cyclic hardening. (Fig. 7c and Fig 7d). Such structures are composed of lines of small point defect clusters and regular alignments of faulted dislocation loops in {111} planes along direction. [10, 11]

References:

[10] M. Heczko, P. Spätig, H. P. Seifert T. Kruml, "Correlation between Dislocation Structures and Mechanical Fatigue Response of 316L Austenitic Steel Loaded with and without Mean Stress at High Temperature in Air and Water Environment" to appear in Key Engineering Materials.

[11] P. Spätig, H.-P. Seifert, M. Heczko, T. Kruml, "Mean Stress Effect on Fatigue Life and Dislocation Microstructures of 316L Austenitic Steel at High Temperature in Air and Water Environment", Paper No 43 of the Proceedings of the Fourth International Conference on Fatigue of Nuclear Reactor Components 28th September – 1st October 2015, Seville, Spain, to be published in NEA webpage in 2016.

[12] G. Facheris, M.-S. Pham, K.G.F. Janssens, S.R. Holdsworth, “Microscopic analysis of the influence of ratcheting on the evolution of dislocation structures observed in AISI 316L stainless steel during low cycle fatigue”, Materials Science and Engineering: A 587 (2013) 1–11.

[13] M.S. Pham, C. Solenthaler, K.G.F. Janssens, S.R. Holdsworth, “Dislocation structure evolution and its effects on cyclic deformation response of AISI 316L stainless steel”, Materials Science and Engineering: A 528 (2011) 3261–3269.

[14] M.S. Pham, S.R. Holdsworth, K.G.F. Janssens, E. Mazza, “Cyclic deformation response of AISI 316L at room temperature: Mechanical behaviour, microstructural evolution, physically-based evolutionary constitutive modelling”, International Journal of Plasticity 47 (2013) 143–164.