CAMEA upgrade of secondary instrument

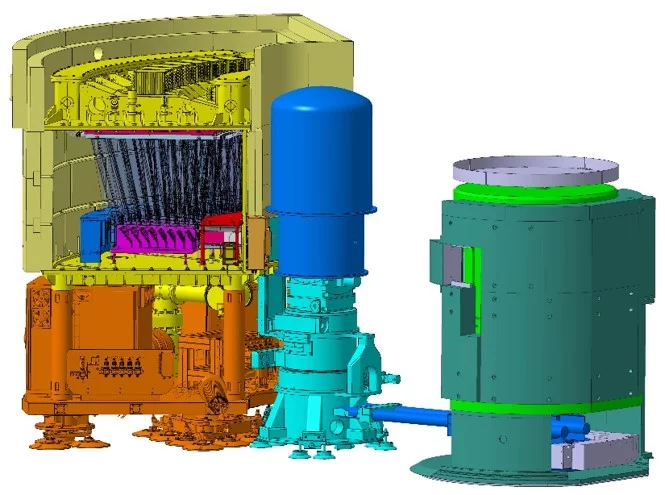

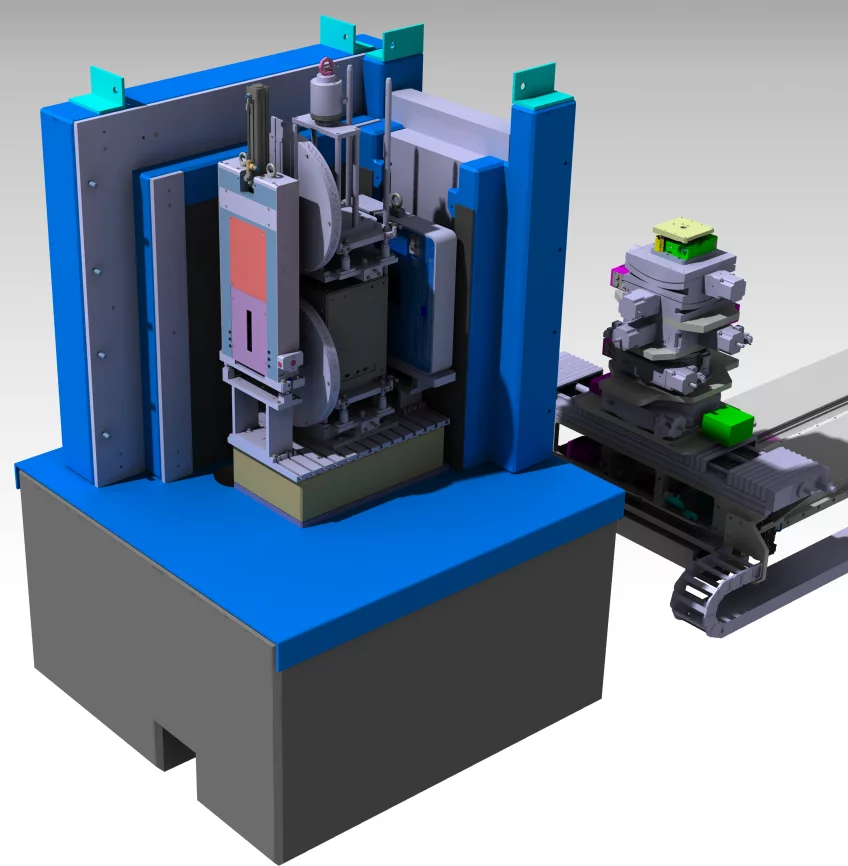

Upgrade

- Old triple axis Rita-II transferred to the multianalyser-box CAMEA

- Sample table reinforced to allow the movement of the heavier analyzer/detector box

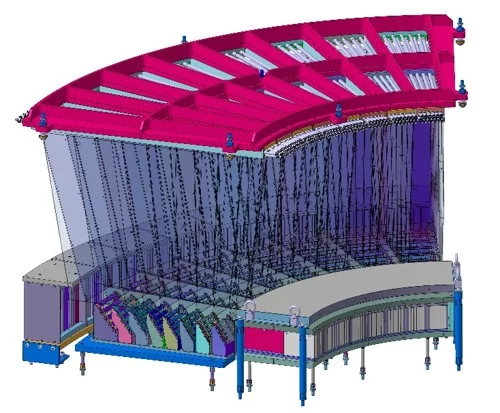

Basic set-up

- Total weight of secondary instrument without sample table ~10 tons

- Shielding polyethylene and borated aluminum

- Vacuum-vessel stainless steel

- Neutron window aluminum

- Be-filter cooled to 77°K

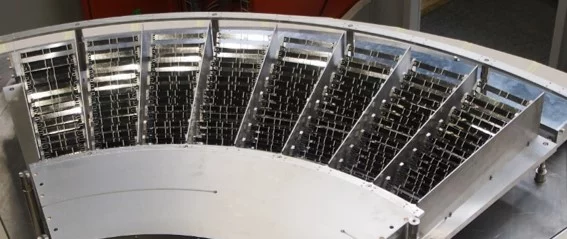

- Radial collimator 1°

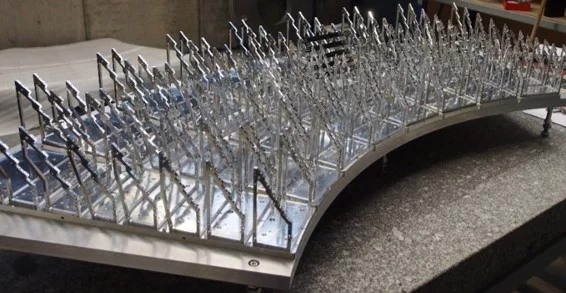

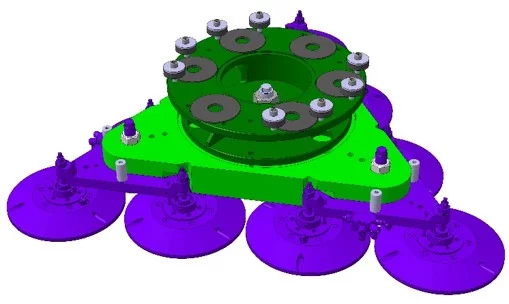

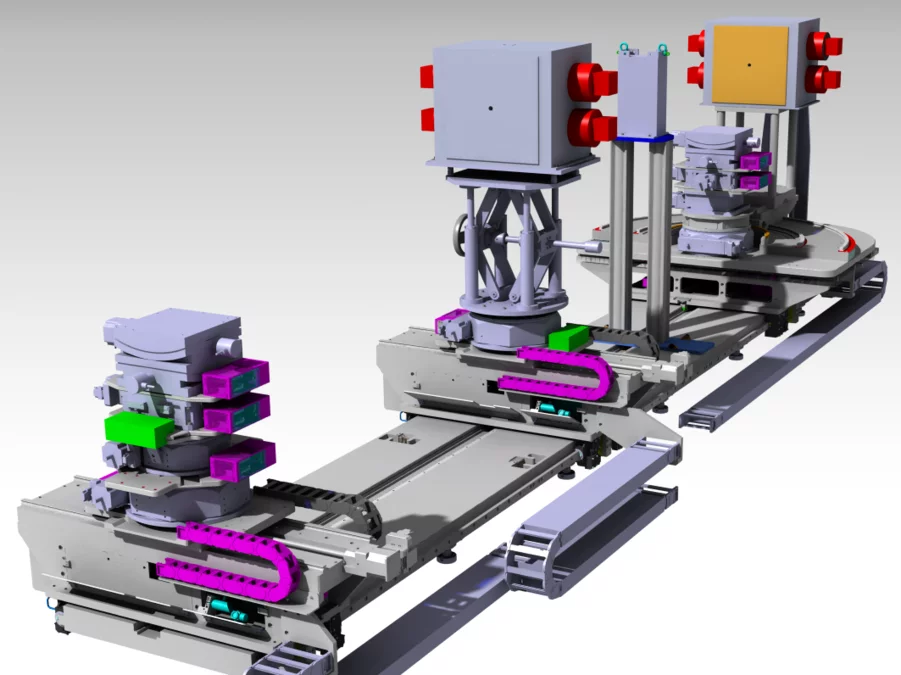

Air cushion assembly

- 15 air cushion pads

- Air cushion lifting stroke 0.06 mm

- Maximal load per pad 800 kg

- Vibration-insulating between instrument components and air cushion assembly

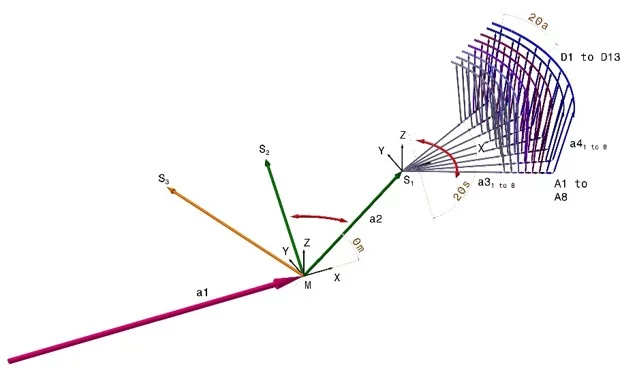

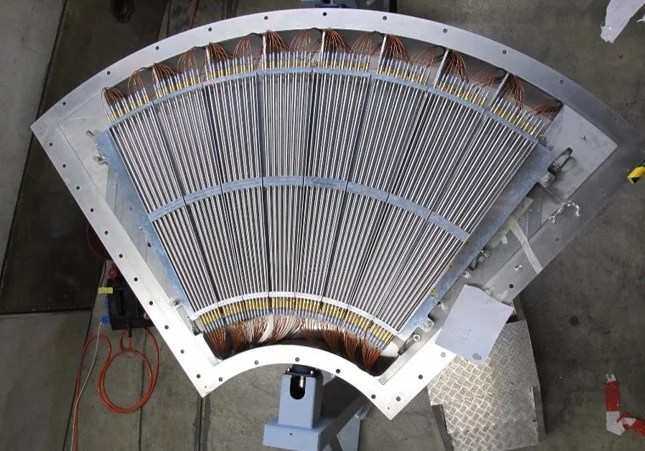

Detector tubes

- 8 x 13 tubes

- Compact construction (sub - ½ inch) for plug and adapter (in-house development)

- Coaxial design

- Detector tubes inside vacuum (tested up to 1e-8 mbar)

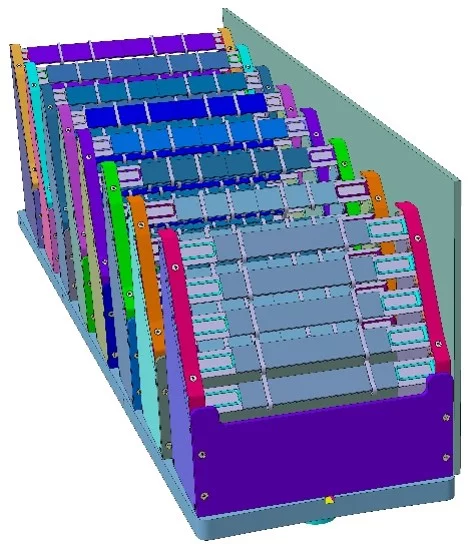

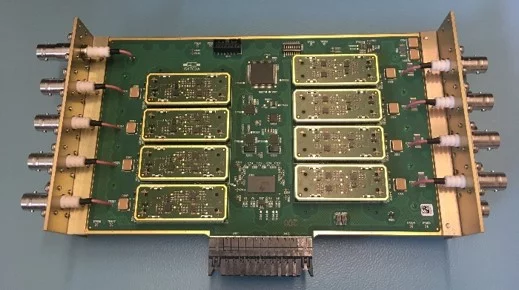

Detector electronics

- Position sensitive data streaming

- Modular design of amplifier stages of the PSD detectors

- Remote service and monitoring possible

- Integration of 2nd generation data acquisition (in-house development)

Other electronics

- Renewal of the complete motion control and PLC system

- Inside "high radiation" use of resolver encoders

- Improved resolver-electronics (in-house development)

- Fully remote controllable

- PLC-integration of the entire vacuum-technics

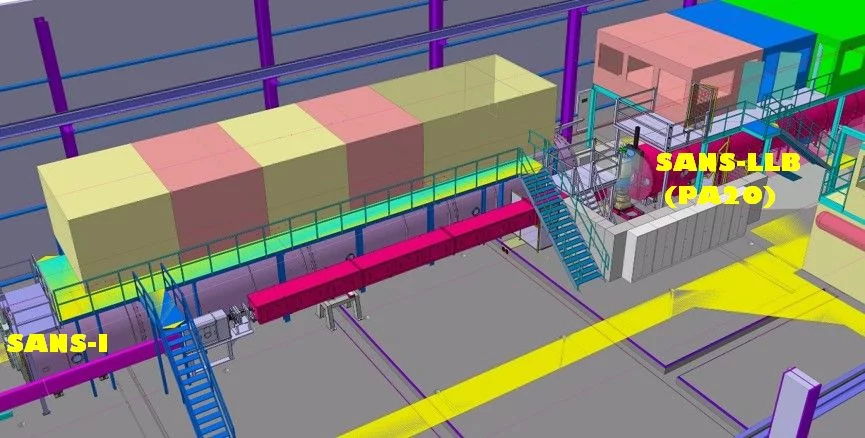

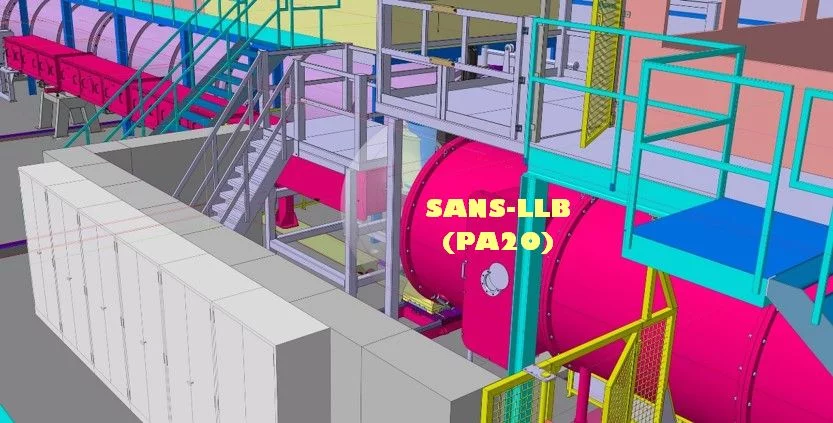

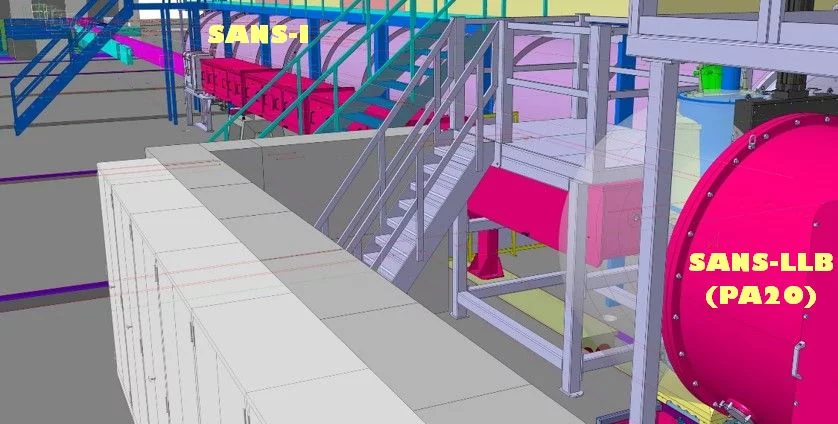

SANS-PA20 LLB Instrument transfer and adaption

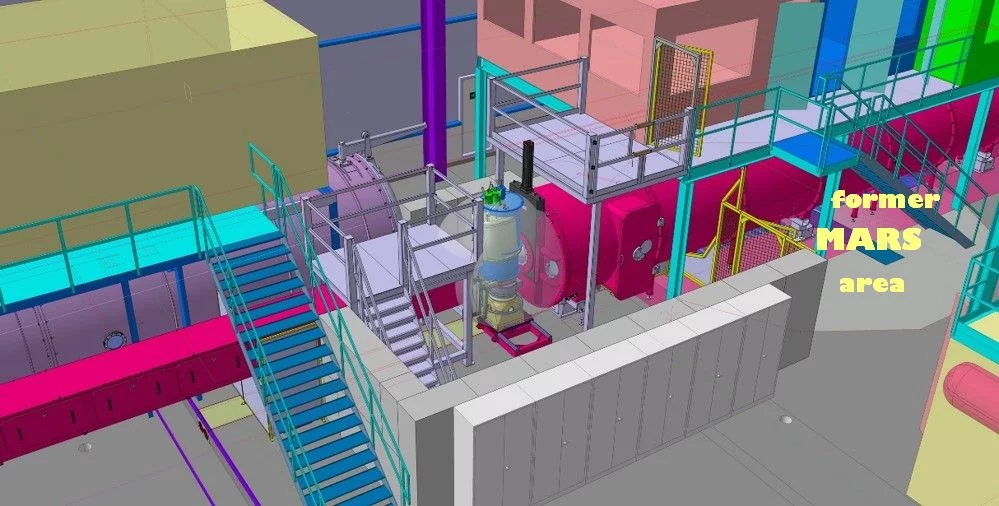

MARS-removal

- Instrument dismantling

- Plasma cutting of aluminum vessel

- Grouting of floor-pit

- Modification of infrastructure (adaption of PA20)

PA20

- 16m collimation

- 19m detector tank

- 2 sets of 3He detectors

Sample table (old table from former SANS-II)

- Adaption of existing SANS-II table

- Built for use with 15 T-magnet (vertical)

- Maximum load 700 kg

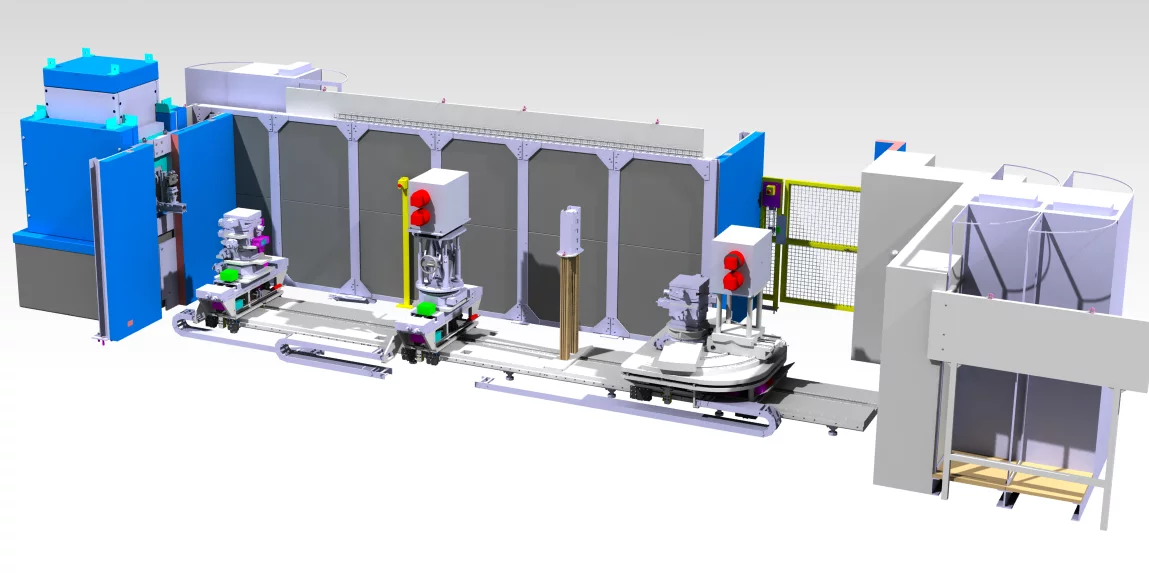

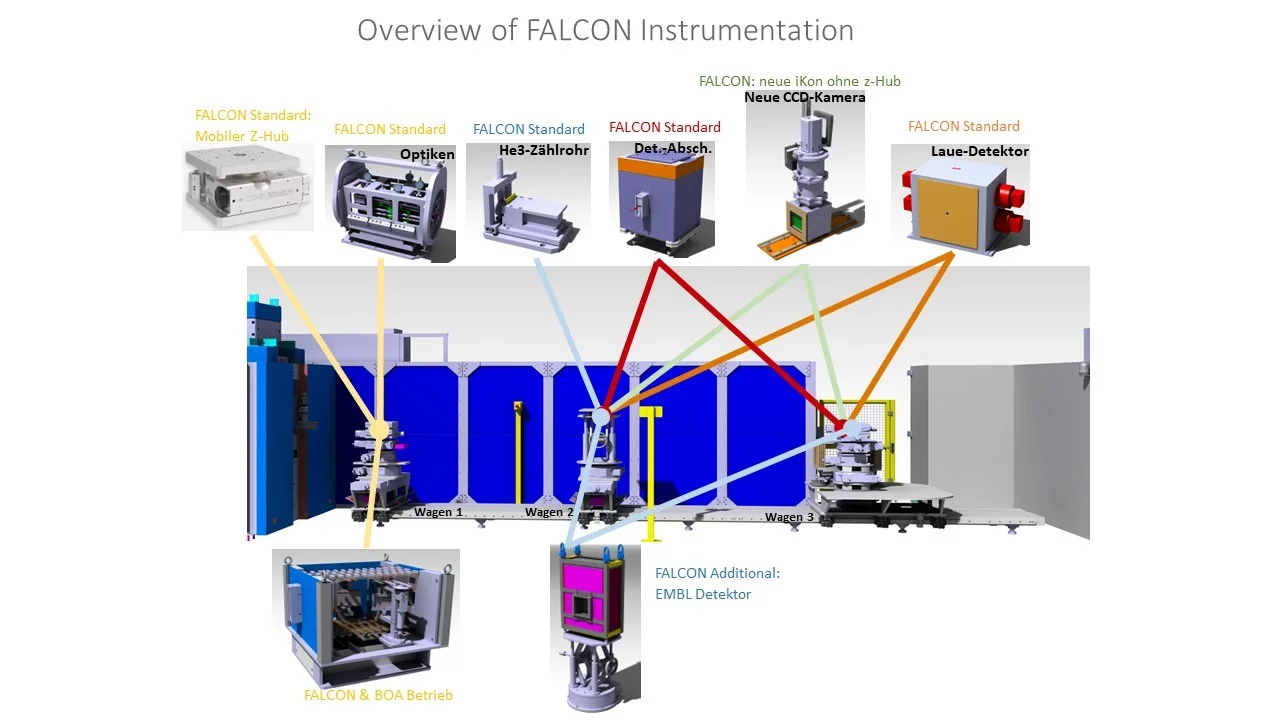

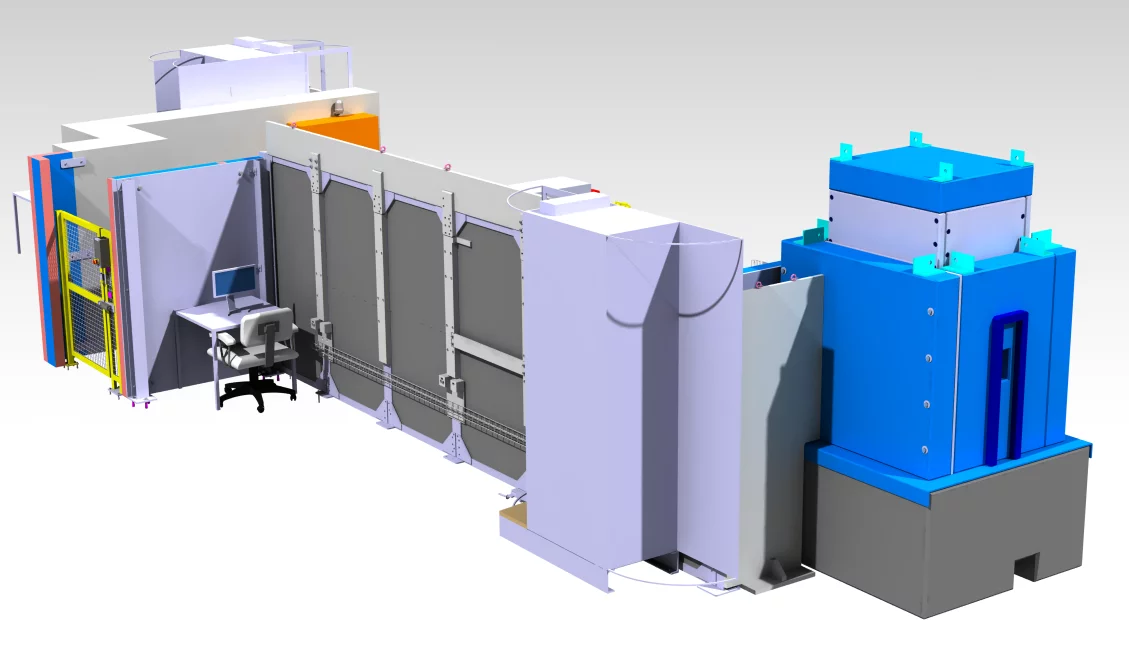

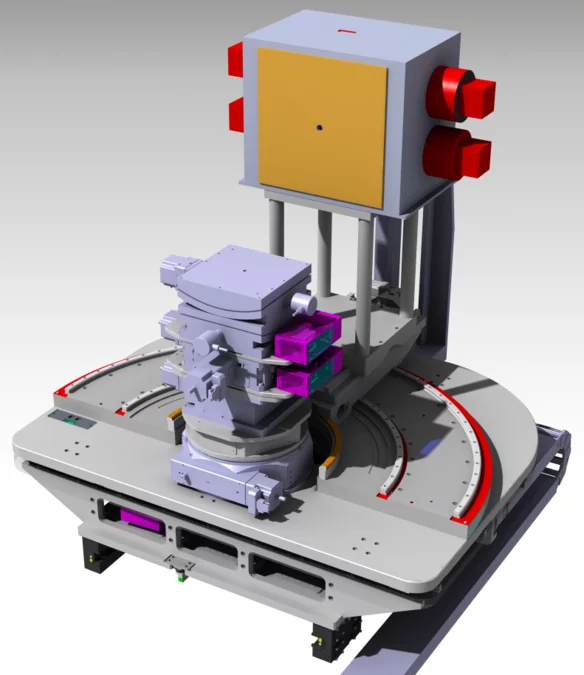

FALCON – a new instrument at SINQ RNR 12 is coming up

Early 2020, an agreement between the Helmholtz-Zentrum Berlin and Paul Scherrer Institut has been signed, according to which the recently commissioned Laue Diffractometer Falcon (E11) would be transferred from HZB to PSI. The purpose of this agreement was to make state-of-the-art equipment from the recently closed research reactor BER-II at HZB work for scientific community at SINQ. German users will have a possibility to continue using the instrument at SINQ.

Area of future Falcon instrument in the SINQ neutron guide hall, at the end of the neutron guide RNR12, is already built.

A Laue camera allowing for fast orientation of single crystals has been missing at SINQ since the beginning. Using the detectors of the original E11 diffractometer from HZB, we will build a modern and versatile instrument at SINQ. FALCON, standing for Fast Acquisition Laue Camera for Neutrons, will allow to quickly assess the quality of single crystals at SINQ, and to align them in specific directions, thus saving a lot of beamtime and work effort at other instruments. The idea is to be able to use the Falcon instrument setup also for different optical applications, and as a test station for components of the future fundamental neutron physics instrument at the ESS.

At the moment, the instrument is being under construction, with a plan to finish the construction in august 2024. Parts of the 3 mobile linear tables and some motion setup is already ordered and will be delivered in the 1st semester 2024. By mid-2024 pre-assembly and partial commissioning work will start. As time progresses, further components will be ordered, assembled, and put into commissioning step by step. We are confident to go in operation with the whole instrument in 2025.