Installation of the first two front ends for the SLS2.0 completed

At the Swiss Light Source SLS of the Paul Scherrer Institute, another important step has been taken towards the completion of the SLS 2.0 upgrade project.

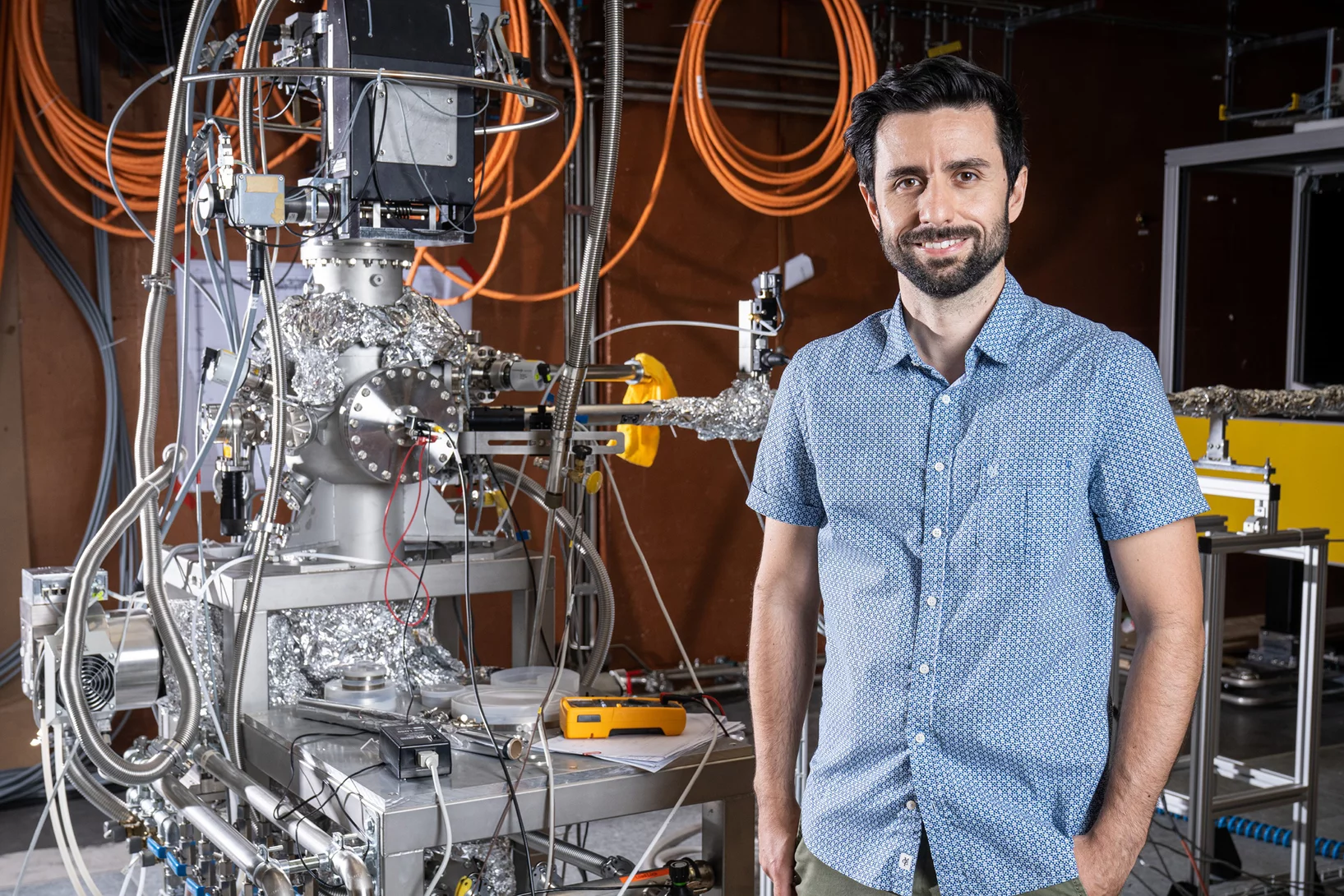

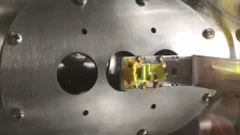

A compact gas attenuator for the SwissFEL ATHOS beamline realized using additive manufacturing

Gas attenuators are important devices providing accurate variation of photon intensity for soft X-ray beamlines. In the SwissFEL ATHOS beamline front-end the space is very limited and an innovative approach has been taken to provide attenuation of three orders of magnitude up to an energy of 1200 eV. Additive manufacturing of a differential pumping system vacuum manifold allowed a triple pumping stage to be realized in a space of less than half a meter. Measurements have shown that the response of the device is as expected from theoretical calculations.

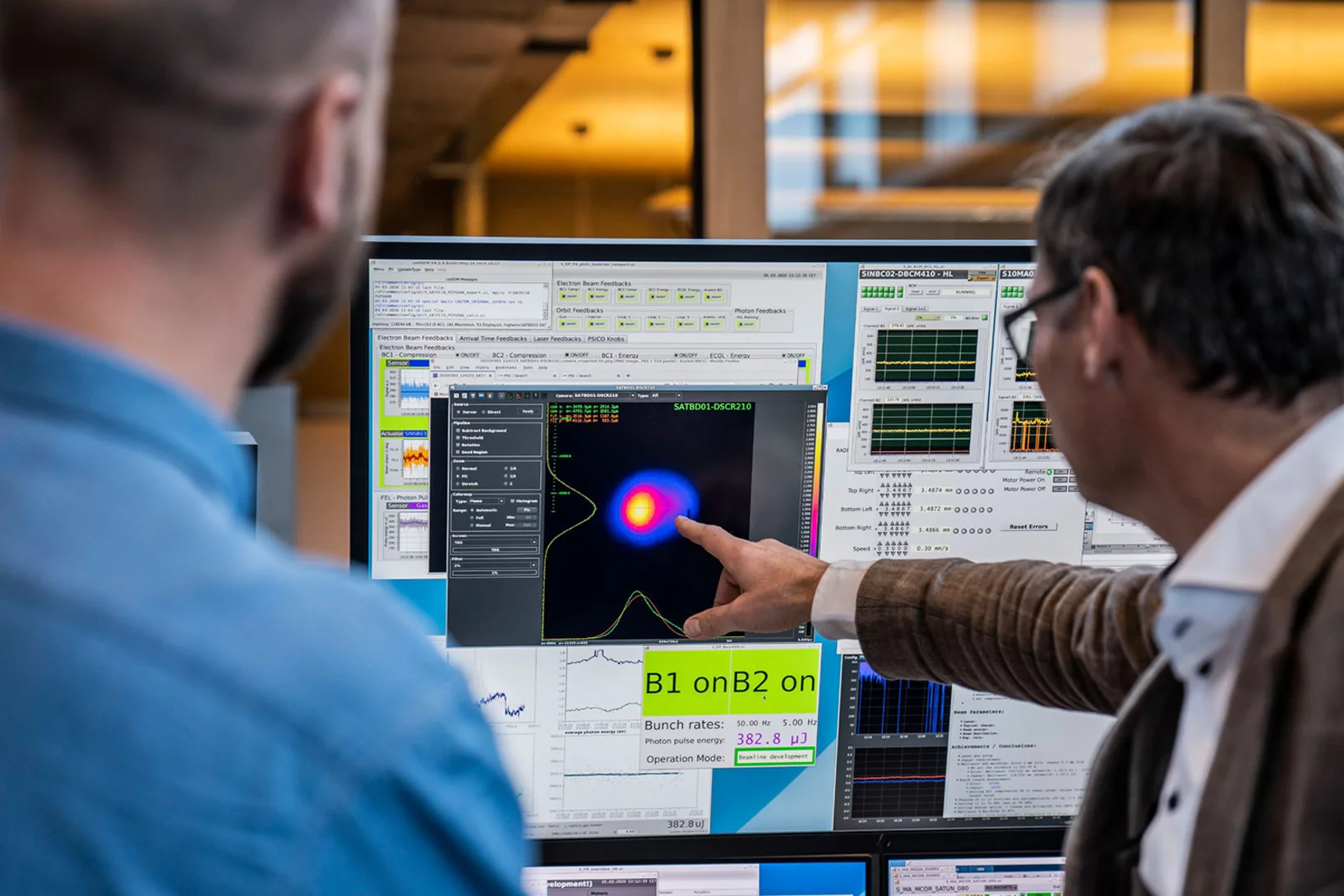

Erstes Licht an Furka: Die Experimente können beginnen

Der Weg zu weltweit einzigartigen Experimenten ist frei.

First light in the SwissFEL Maloja endstation

The first endstation at the SwissFEL Athos soft X-ray branch is rapidly developing and on track for first experiments in 2021.

SwissFEL: «Athos» macht grosse Fortschritte

Die neue Strahllinie am Freie-Elektronen-Röntgenlaser SwissFEL des PSI ist schon bald einsatzbereit. Im Dezember lieferte «Athos» das erste Mal Laserlicht − zur Freude der Forschenden, die mit dem Aufbau betreut sind, sogar früher als erwartet.

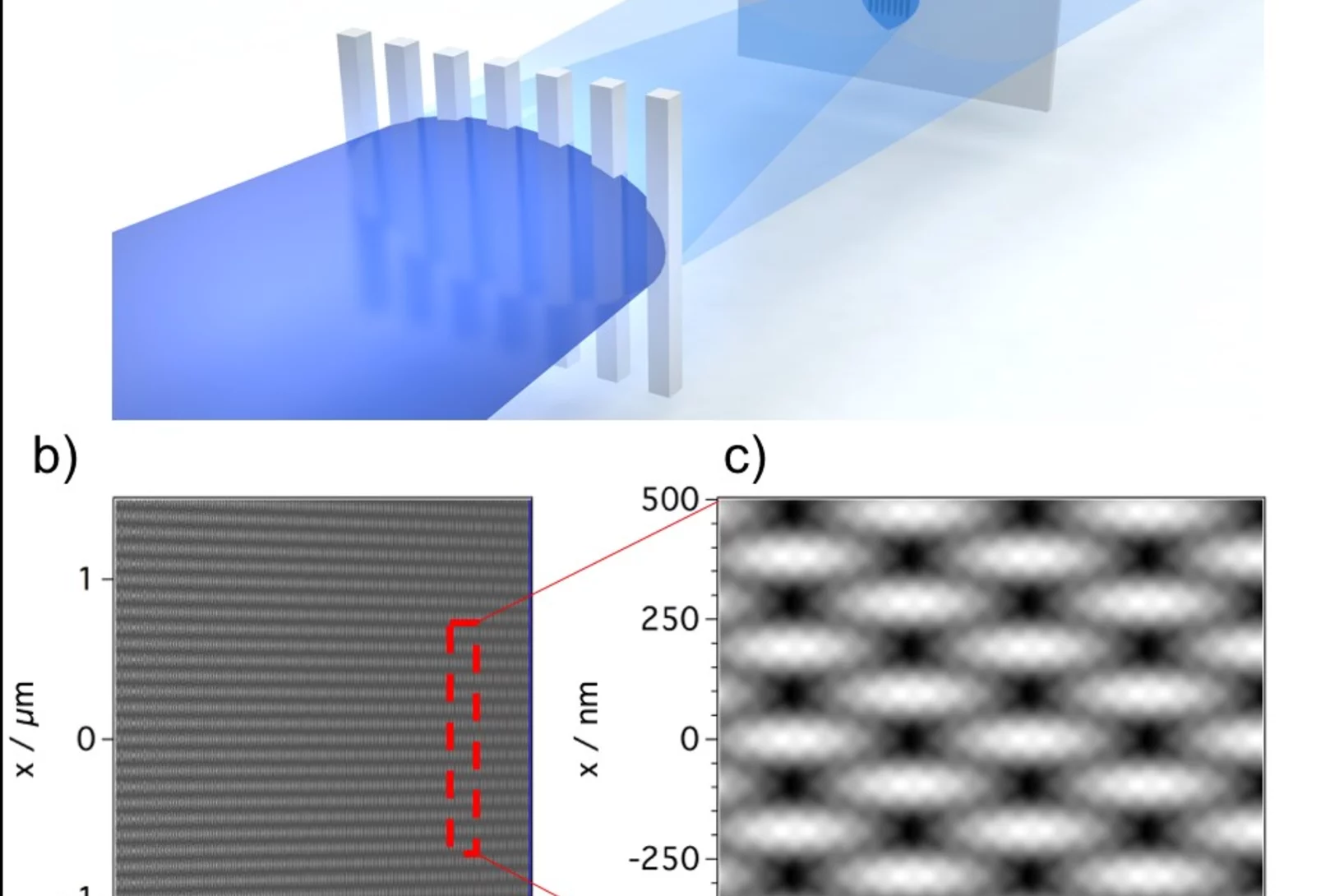

Towards X-ray Transient Grating Spectroscopy at SwissFEL

The high brilliance of new X-ray sources such as X-ray Free Electron Laser opens the way to non-linear spectroscopies. These techniques can probe ultrafast matter dynamics that would otherwise be inaccessible. One of these techniques, Transient Grating, involves the creation of a transient excitation grating by crossing X-ray beams on the sample. Scientists at PSI have realized a demonstration of such crossing by using an innovative approach well suited for the hard X-ray regime.

Erstes Experiment am SwissFEL erfolgreich durchgeführt

Die Jahre des sorgsamen Planens und Aufbauens haben sich ausgezahlt: An der neuesten Grossforschungsanlage des Paul Scherrer Instituts PSI – dem Freie-Elektronen-Röntgenlaser SwissFEL – wurde das erste Experiment erfolgreich durchgeführt. Damit wurden zwei Ziele erreicht: Erstens gibt es schon gleich ein neues wissenschaftliches Ergebnis. Zweitens wird damit das Zusammenspiel der vielen Einzelkomponenten der hochkomplexen Anlage optimiert.

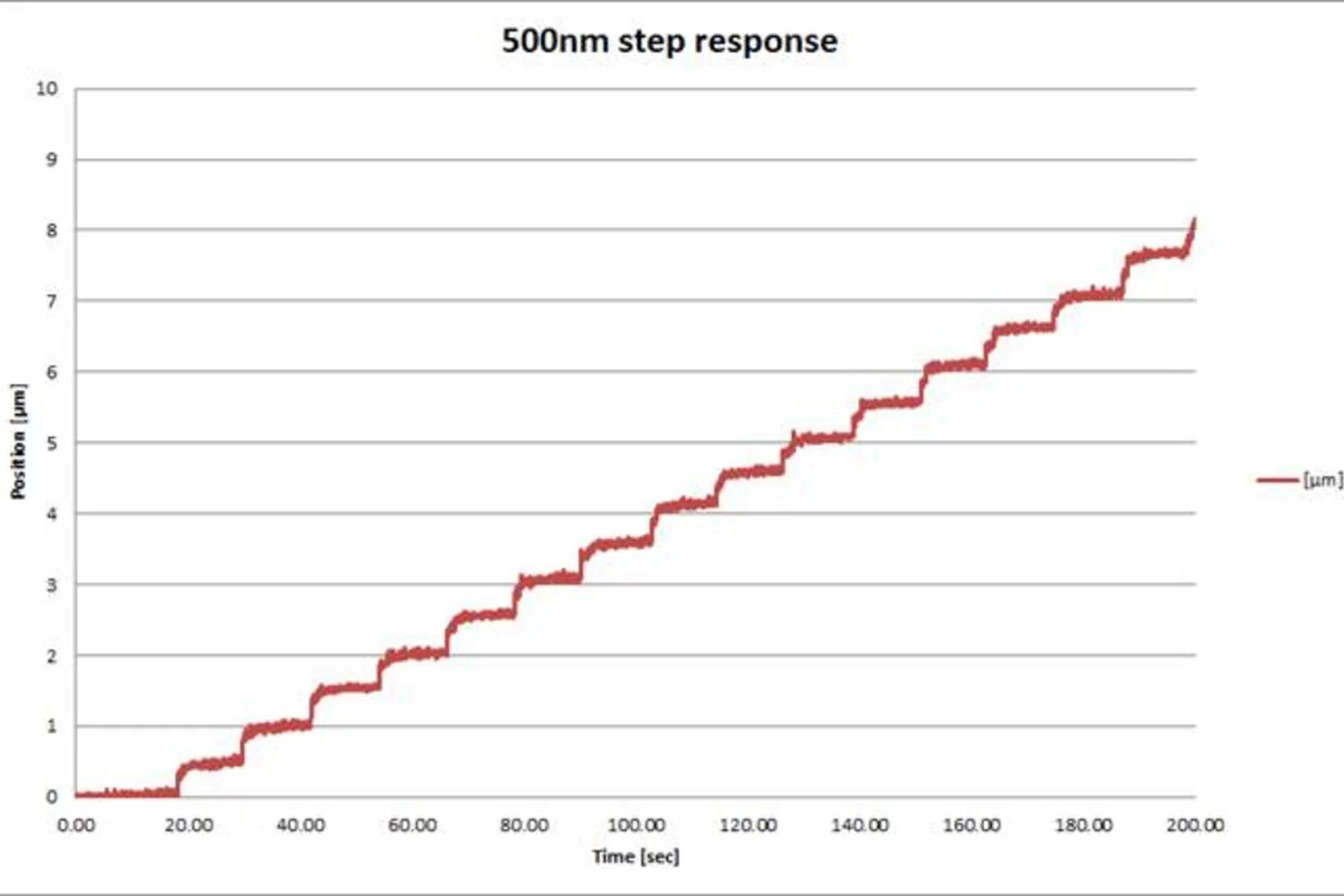

High-Precision Vertical Linear Translation for Offset Mirrors

The horizontal and vertical offset mirrors are key optical elements for the SwissFEL ARAMIS Beamline. The offset mirrors for example, are used to deflect and steer the x-ray beam into one of the end stations. As the sample position is about 60m from the mirror, very high demands are put on the mirror positioning system in order to deflect the x-ray beam on to the sample with a micro-meter precision. Therefore precise positioning of the mirrors is required, with specifications to move a load of up to 200kg by steps as small as 0.3µm. Not just the positioning must be precise, but also the stability for short term vibrations and long term drifts must be superior.