High-temperature gas-cooled reactors using pebble-bed cores have been proposed because of their distinct safety advantages when compared to other reactor technologies. However, safety issues were identified in prototype reactor experiments, such as the release of fission products from coated particles due to local high temperatures, graphite dust formation, and the transport and release of radionuclides with the dust.

Graphite dust formation is one of the important issues recognized for the HTR operation and safety, especially in pebble bed type reactors. Dust is generated in HTRs by several mechanisms, one of the most significant ones being the abrasion of graphite when graphite parts move relative to each other, or relative to metal parts in the reactor or abrasion by high gas velocities. The amount or characteristics of the dust are not known. The generated dust may become contaminated by the leakage of radioactive compounds from the fuel particles.

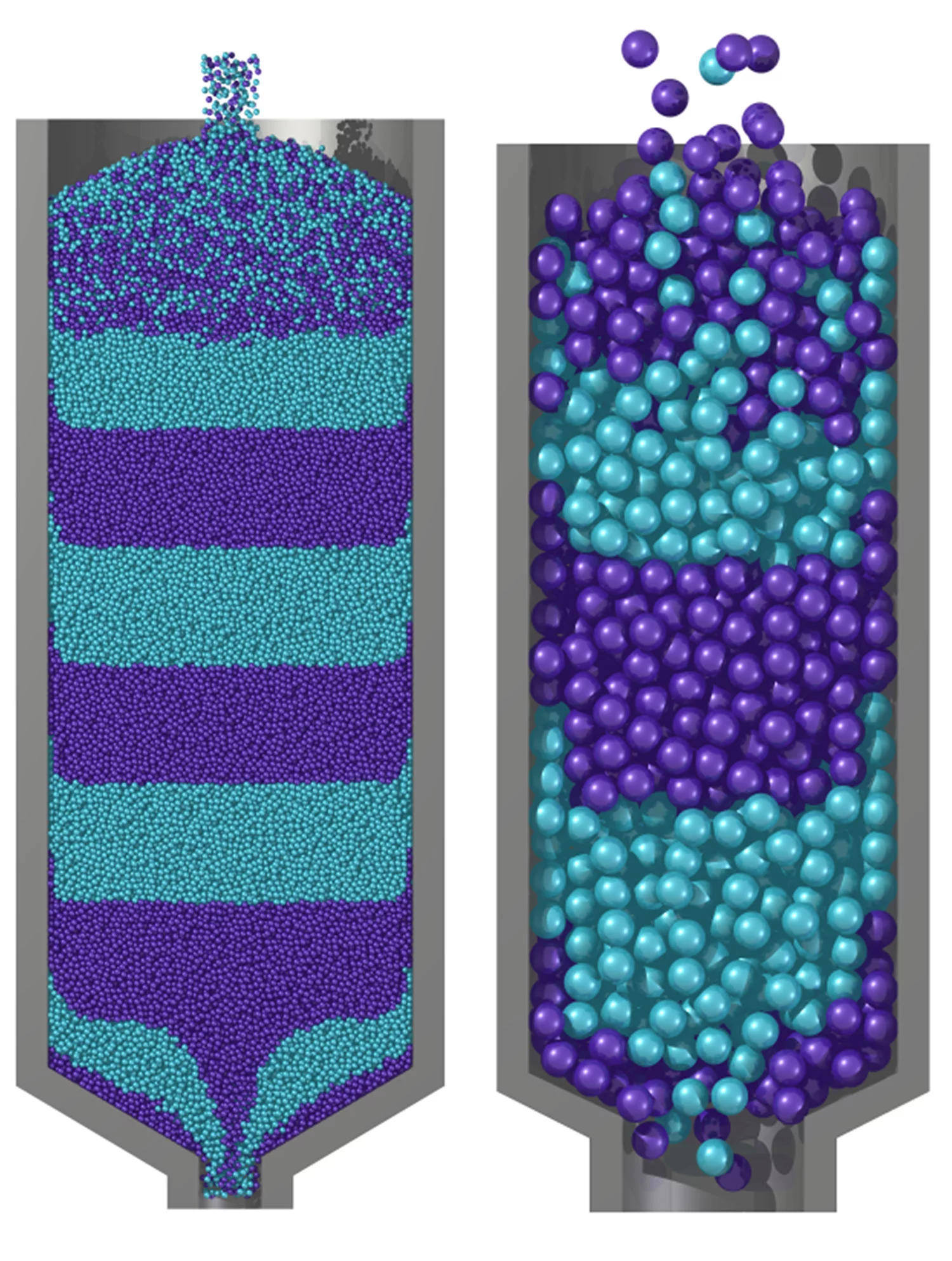

At the high temperatures and pressures in these reactors, little data is available to understand the frictional properties of the pebble surfaces and the subsequent dust formation tendency. To investigate the dust formation, simulations of granular flow in pebble bed reactors using the discrete-element method (DEM) have been performed. Simulations in the full geometry (using 440,000 pebbles) are compared to those in geometries scaled down by 3:1 and 6:1. The simulations show complex behavior due to discrete pebble packing effects, meaning that pebble flow and dust generation in a scaled-down facility may be significantly different from the real-scale reactor. The differences between velocity profiles, packing geometry, and pebble wear between the different scales have been documented. The results can aid the design of the prototypical facility to more accurately reproduce the flow in a full-size reactor.

Video

Graphite dust formation is one of the important issues recognized for the HTR operation and safety, especially in pebble bed type reactors. Dust is generated in HTRs by several mechanisms, one of the most significant ones being the abrasion of graphite when graphite parts move relative to each other, or relative to metal parts in the reactor or abrasion by high gas velocities. The amount or characteristics of the dust are not known. The generated dust may become contaminated by the leakage of radioactive compounds from the fuel particles.

At the high temperatures and pressures in these reactors, little data is available to understand the frictional properties of the pebble surfaces and the subsequent dust formation tendency. To investigate the dust formation, simulations of granular flow in pebble bed reactors using the discrete-element method (DEM) have been performed. Simulations in the full geometry (using 440,000 pebbles) are compared to those in geometries scaled down by 3:1 and 6:1. The simulations show complex behavior due to discrete pebble packing effects, meaning that pebble flow and dust generation in a scaled-down facility may be significantly different from the real-scale reactor. The differences between velocity profiles, packing geometry, and pebble wear between the different scales have been documented. The results can aid the design of the prototypical facility to more accurately reproduce the flow in a full-size reactor.

Video

Reference

Granular Flow in pebble-bed nuclear reactors: Scaling, Dust Generation, and Stress

Rycroft C., Dehbi A., Lind T.M., Guentay S.

Nuclear Engineering and Design, 265, 69-84, 2013

DOI: Paper

Rycroft C., Dehbi A., Lind T.M., Guentay S.

Nuclear Engineering and Design, 265, 69-84, 2013

DOI: Paper