Introduction

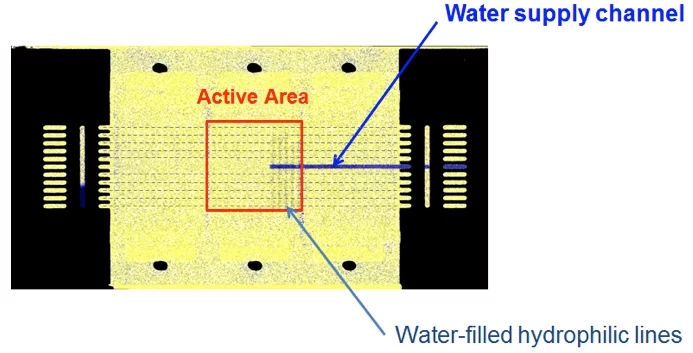

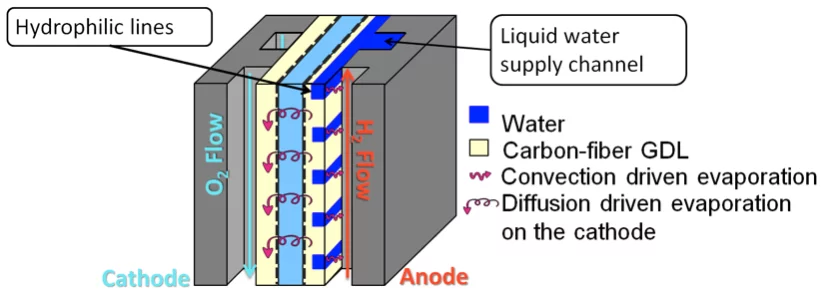

In the framework of the SCCER Mobility, we developed a concept of evaporative cooling where water is brought through channels in the anode flowfields, parallel to the gas channels, and wicked by capillarity into the Gas Diffusion Layers (GDL). Although the GDLS are originally hydrophobic thin porous media, a synthetic method developed at PSI [1, 2] allows us to turn them into a succession of hydrophobic and hydrophilic surfaces. The hydrophilic lines can wick liquid water at near negative capillary pressures, while the hydrophobic zones remain dry for capillary pressures as high as 40mbars [3]. As a result the hydrophilic lines can be used to distribute the cooling water over the GDL surface in a controlled fashion, while the hydrophobic lines remain dry pathways for the reactant gases.

The hydrophilic lines are placed perpendicular to the gas and water channels, so that the water they transport is evaporated by convection at the contact of the flowing gas, thus providing cooling and humidification for the cell. The water vapor once evaporated can be removed either on the anode, or after diffusion through all the layers of the cell on the cathode side.

In a first phase of this project, a thermal test cell was built, which allowed controlling the thermal boundary conditions and precisely measuring the heat fluxes due to the evaporation within the cell, with and without electrochemical reaction. By combining these measurements with images from Neutron Radiography, we could establish a simple 1D model that can predict the evaporation rate achievable with our special GDLs for the following parameters: gas flow rates, temperature, pressure, geometry and separation of the hydrophilic lines [4]. This simple 1D model enables us to estimate the conditions for which our scheme will provide enough cooling power for an operating cell.

References

[1]

-

Forner-Cuenca A, Biesdorf J, Gubler L, Kristiansen PM, Schmidt TJ, Boillat P

Engineered water highways in fuel cells: radiation grafting of gas diffusion layers

Advanced Materials. 2015; 27(41): 6317-6322. https://doi.org/10.1002/adma.201503557

DORA PSI

[2]

-

Forner-Cuenca A, Biesdorf J, Manzi-Orezzoli V, Gubler L, Schmidt TJ, Boillat P

Advanced water management in PEFCs: diffusion layers with patterned wettability. III. operando characterization with neutron imaging

In: Savinell RF, ed. Vol. 163. Journal of the electrochemical society. sine loco: ECS; 2016:F1389-F1398. https://doi.org/10.1149/2.0891613jes

DORA PSI

[3]

-

Forner-Cuenca A, Biesdorf J, Lamibrac A, Manzi-Orezzoli V, Büchi FN, Gubler L, et al.

Advanced water management in PEFCs: diffusion layers with patterned wettability. II. measurement of capillary pressure characteristic with neutron and synchrotron imaging

Journal of the Electrochemical Society. 2016; 163(9): F1038-F1048. https://doi.org/10.1149/2.0511609jes

DORA PSI

[4]

-

Cochet M, Forner-Cuenca A, Manzi V, Siegwart M, Scheuble D, Boillat P

Novel concept for evaporative cooling of fuel cells: an experimental study based on neutron imaging

Fuel Cells. 2018; 18(5): 619-626. https://doi.org/10.1002/fuce.201700232

DORA PSI

Contact

Dr. Pierre Boillat

Electrochemistry Laboratory (LEC) and

Neutron Imaging and Activation Group (NIAG)

5232 Villigen PSI

Switzerland

Telephone: +41 56 310 2743

Fax +41 56 310 4415

Email: pierre.boillat@psi.ch