The ability to start-up in extreme environmental conditions, including sub-freezing temperatures, is essential to the deployment of the fuel cell technology. Water produced in fuel cells at these temperatures can be in the super-cooled state, and freezing can lead to a rapid shutdown, as water cannot be removed anymore as a liquid. By segmenting a fuel cell, it is possible to prevent the propagation of freezing, which enables the cell operation even after the first freezing event occurred.

Freezing in super-cooled water is a stochastic event, the probability of which depends on the degree of super-cooling. Once freezing occurs in a particular location, it rapidly propagates to the whole volume of water connected to this location. Fuel cells of larger dimensions result in a higher probability of freezing in a given amount of time compared smaller cells, because the volume of accumulated water is greater. The segmentation of water into distinct clusters has, therefore, the potential of extending the operation time of fuel cells at low temperature. Even when the first freezing occurs, ice propagation is limited within one segment, and the rest of the segments can further operate.

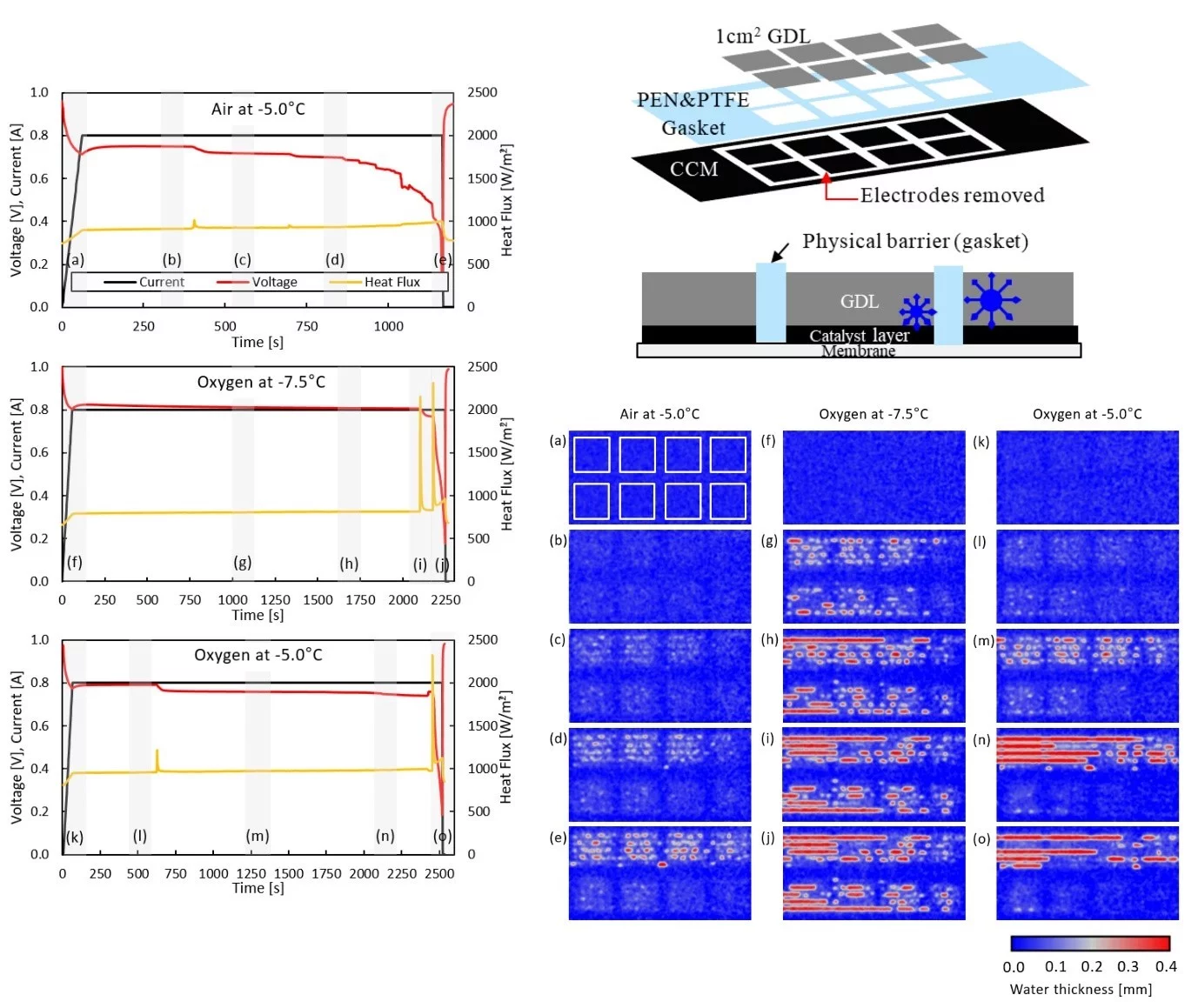

To evaluate the feasibility of this approach, a cell with an active area of 8 cm2 was physically segmented into 8 separate regions. The segmentation was done on the catalyst layer by laser ablation and on the gas diffusion layer by mechanical cutting, while the membrane and flow fields were not segmented. The fuel cell was started and operated at constant temperatures of -5°C and -7.5°C, using either air or pure oxygen as cathode gas. Several methods were used to analyze the freezing events during cell operation. Heat flux sensors were able to detect the exothermal peaks corresponding to freezing with a high temporal precision, but without a precise identification of the freezing location. The water distribution measured by neutron imaging allowed indirectly to identify the location of frozen sections, as the absence of electrochemical reaction was evidenced by the fact that no more water was produced.

The possibilities and challenges of the segmentation approach are illustrated in 3 start-up experiments as shown in the figure. In the first experiment, the cell was started and operated at a temperature of -5 °C using air at the cathode. The first freezing occurs (as evidenced by the exothermal peak) after 350s, but the cell could further be operated. As shown from the subsequent water distribution images (c-e), water was only produced in the upper section of the cell, indicating that the lower segments were frozen. Starting at approximately 800s, the cell voltage gradually degraded, and the cell finally reached shutdown. In this case, the shutdown was not attributed to a further freezing, but to the fact that when the water produced in the upper segments reached the flow channels, the gas flow was impeded and tended to redistribute towards the lower section of the cell. Eventually, this resulted in severe mass transport losses leading the shutdown.

To support this hypothesis, startups were analyzed using pure oxygen in the cathode, in which case mass transport was not impeded even when the gas flow suffered from an important imbalance between the upper and lower segments. The experiments using pure oxygen did not exhibit the gradual decrease of voltage seen with air. In both experiments with pure oxygen, two different freezing events were observed, the second leading to a rapid shutdown of the cell.

Our study demonstrates that segmentation of the electrodes and GDL can extend the operation time of fuel cells under sub-zero temperature, which could allow non-assisted start-ups from extreme temperatures. However, in all experiments performed, the segmentation was only effective between the upper and lower sections of the cell. Furthermore, in the case where water reached the gas flow channels, the impact of water accumulation on gas flow distribution led to sever mass transport issues. This limited the duration of cell operation, but overall the prolonged operation time was confirmed thanks to segmentation that could contribute to a successful start-up.

Contact

Dr. Pierre Boillat

Head of Neutron Imaging of Electrochemical Systems Group

Paul Scherrer Institut

5232 Villigen PSI

Switzerland

Telephone: +41 56 310 27 43

E-mail: pierre.boillat@psi.ch

Dr. Jongmin Lee, PostDoc

Neutron Imaging of Electrochemical Systems Group

Paul Scherrer Institut

5232 Villigen PSI

Switzerland

Telephone: +41 56 310 27 46

E-mail: jongmin.lee@psi.ch

Original Publication

J. Lee et al.

to be submitted

DOI: tbd

Acknowledgement to Funding Agency

The authors thank the SNSF for funding this project under the 185085.