Feasibility and plausibility of innovative reactor concepts in an European electricity supply environment” PSEL project in PSI

In this project, we have looked into two nuclear reactor concepts with distinctive safety features, namely: the High Temperature Gas-cooled Reactor (HTGR) and the Molten Salt Reactor (MSR). In the HTGR, these safety features stem from the TRISO particle fuel made from a small fuel grains surrounded by a silicon carbide coating, which is able to retain the radioactive fission products even in elevated accident temperatures. In so-called pebble bed reactors, which were in the main focus of the this project, coated fuel particles are encased to a fuel spheres made of graphite, providing one more barrier for the activity release. An even more drastic change in the safety philosophy is characteristic of MSRs with liquid fuel. The first and most important barrier encapsulating the huge radioactive inventory of the fuel is missing completely in this class of reactors. This is replaced by the opportunity for permanent access to all isotopes accumulated in the fuel, which can be extracted continuously by treating a bypass flow from the reactor circuit. In this way a large share of the radioactive inventory can be removed on during operation.

Both pebble bed HTGRs and MSRs are far from being just paper reactors on the drawing board. Two pebble bed reactor prototypes were built and operated in Germany, namely the AVR and the THTR. On the basis of the experience with these reactors, the concept of a modular pebble bed reactor was developed, which includes the safety features mentioned above. Recently, China has built a prototype at the Tsinghua University with 10 MW thermal power (HTR-10). The construction of the HTR-PM prototype plant was started in Weihai in Shan Dong province, and is now almost finished. After the termination of the South-African PMBR project, the Chinese projects are the only substantial activities concerning pebble bed reactors worldwide. The first experimental molten salt reactor was built and successfully tested in the Aircraft Propulsion Reactor project of the Oak Ridge National Laboratory, namely the Aircraft Reactor Experiment (ARE, 1954) and the Molten Salt Reactor Experiment (MSRE, 1965 – 1968). There is a wide variety of project studies on the way worldwide, which aim at taking benefit from the experience of these early experiments.

Between the years 2015 and 2019, Paul Scherrer Institut coordinated a project where pebble bed HTGRs aside with MSR concepts and the use of thorium fuel were investigated. The project involved different groups from the ETH domain and the main purpose is to build-up the specific HTGR know-how in Switzerland that is necessary to provide in-depth information to decision makers and identify research needs for the future. Several key aspects of both HTGR and MSR reactors were addressed in this research project, which include:

Qualitative study of accident phenomenology in HTGR

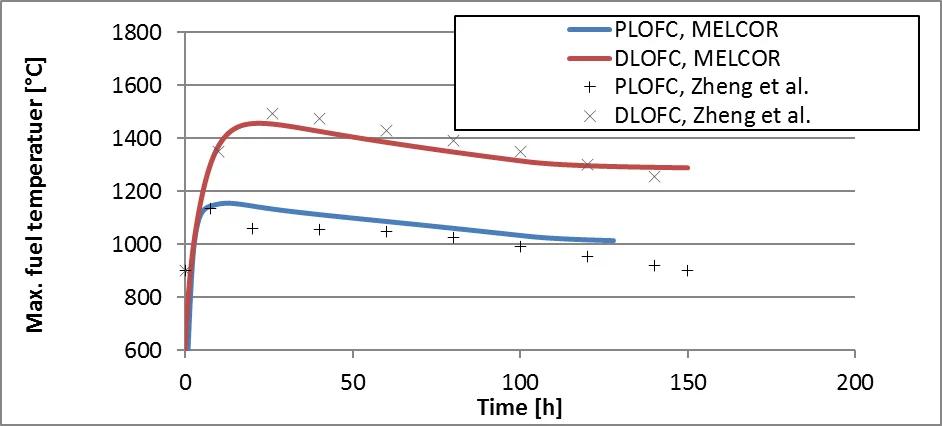

Enhanced safety features of modular pebble bed reactors are frequently brought up as a striking advantage of this reactor type over current LWRs. On the other side, inherent safety features preventing core damage due to an unprotected loss-of-flow in the reactor core does not cover the full scope of all potential accident scenarios. In this project a large literature review on possible accident sequences in HTGR was performed and simulation of Pressurized and De-pressurized loss of forced flow accidents (PLOFC/DLOFC) in the HTR-PM were performed using the MELCOR severe accident code (Kalilainen et al., 2018). The results were found to compare well with the previously published safety studies (Fig. 1).

Economic assessment

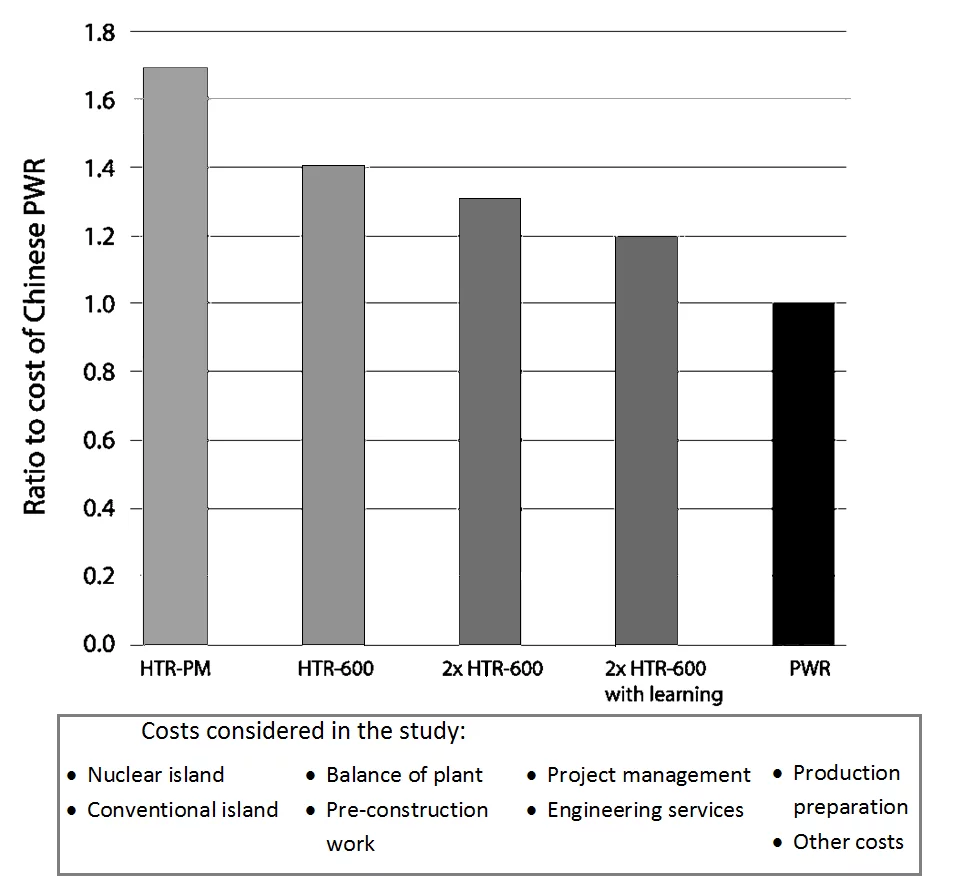

The economic assessment work focused on how to estimate future capital costs for Small Modular Reactor (SMR) designs. The effort focused on integral PWR (iPWR) designs, due to their current dominance in proposed SMR designs, and the HTGR, due to the interest and data available from Chinese partners. The iPWR effort chose similar PWR designs, and estimated cost reductions due to design simplification, reduced construction time, equipment sharing, contingency costs for first-of-a-kind units, and learning curve effects. The estimated costs were then compared to published cost estimates for 4 SMR designs. The HTGR effort took cost breakdown data from Chinese partners and estimated costs for a scale up to a 600 MWe design, shared equipment cost reductions for a 2x600 MWe plant, and further learning curve cost reductions, as shown in Fig. 2. The cost reductions are expressed in comparison to a reference Chinese Generation II+ CPR1000 design, using the costs of the Fuqing 1-3 reactors.

Preliminary study on reduction of waste volume on HTGRs

Fuel spheres in a pebble bed reactor have a comparatively low average heavy metal content per unit core volume. This also remains true for the pebble bed volume in a cask used for direct deep geological waste disposal. In case of the HTR-PM, the UO2 content of a single pebble is only 7 g in a sphere of 60 mm diameter. This leads to prohibitively high back end costs, because the driving parameter is the waste volume rather than the total contained radiotoxicity. Within the framework of the present project, a comparison with spent fuel from light water reactors was made, showing that roughly 40 times higher High Level waste (HLW) volumes can be expected. Additionally, it was shown that a separation of the matrix graphite of the pebble from the coated particles they contain, and a separate disposal of the graphite as low level waste (LLW) can lead to a drastic reduction of the costs of the deep geological repository. This is caused by the very different specific costs of LLW and HLW disposal.

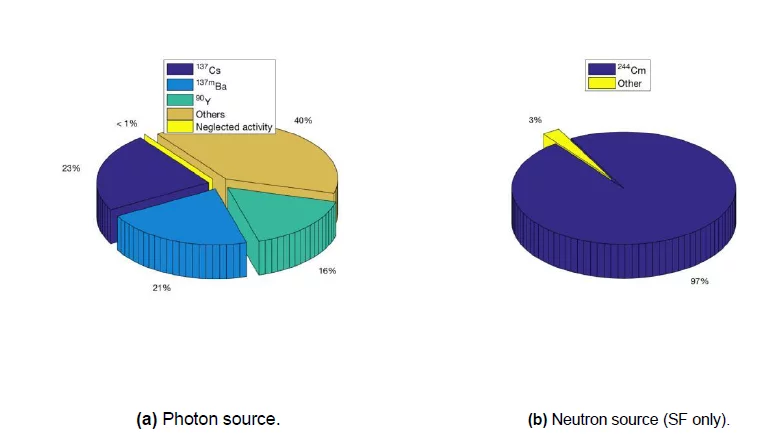

On possible technique for the matrix graphite separation is the high voltage pulse power fragmentation (HVPPF). In this project, a container suitable for the HVPPF of an irradiated fuel pebble was designed. Activity inventory of irradiated pebbles after a prototypal burnup of 90 GWd/t-HM was calculated (Fig. 3), where the gamma activity after 10 years of cooling is 2.6.1011 Bq = 7 Ci per pebble, whereas the neutron activity is 1.5.103 Bq. A canister, where the test crucible was embedded into a shielding mantle was designed and MCNP5 calculations were carried out. The mass of the canister was 1100 kg, including a preliminary electrode design and dose rates at the outside complied with regulations for use inside a temporary controlled area (below 0.5 μSv/h).

Optimization of the fuel cycle for HTGR and MSR

From the two reactors considered in this project, especially the MSR offers especially strong opportunities for breeding and transmutation. Studying the neutronic properties of different core configurations of both reactor concepts is important to understand their potential contribution to an optimization of the nuclear fuel cycle.

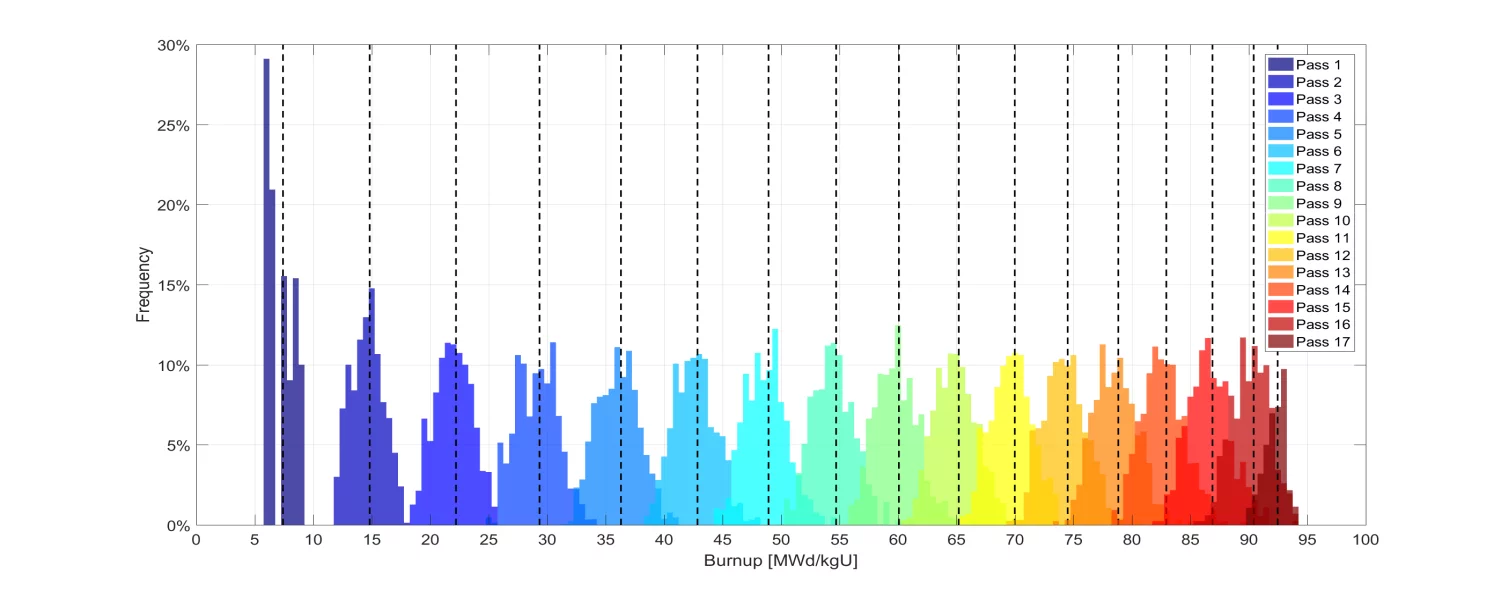

For the HTR-PM, the equilibrium open cycle was simulated using a dedicated burnup script MPB. The study analyzed also the reactor physics specific for the HTGR and identified that the pebbles act as a pseudo-liquid, which tends to homogenize the average fuel properties in the core. With an increase in the number of pebbles passing through the core the maximum and minimum burnups converge (see Fig 4). The simulation also confirmed that activity of 137Cs can be used for burnup detection with acceptable accuracy (Vitullo et al., 2019).

Contact

Severe ACcident REsearch group (SACRE)

Laboratory for Reactor Physics and Thermal-Hydraulics (LRT)

Nuclear Energy and Safety Research Division (NES)

Paul Scherrer Institut

Original Publications

Vitullo, F., Krepel, J., Kalilainen, J., Prasser, H.-M., Pautz, A.,

Statistical Burnup Distribution of Moving Pebbles in HTR-PM reactor

Nuclear Engineering and Radiation Science, 2020, Vol.6 (2)

Kalilainen, J., Schenler, W., Krepel, J., Lind, T., Prasser, H.-M.

High temperature gas-cooled reactors in a European electricity supply environment; main outcomes of a project in PSI

Nuclear Science and Technology Symposium – SYP2019, Helsinki, Finland, October 30-31 2019.

Kalilainen, J., Lind, T., Prasser, H.-M.

Loss of Forced Cooling accident analysis of HTR-PM using MELCOR 2.2 Code

Proceedings of HTR 2018, Warsaw, Poland, October 8-10 2018.

Sisl, V., Krepel, J.

Mixed LEU-Th Initial Core and Running-In Phase for the HTR-PM Reactor.

Proceedings of HTR 2018, Warsaw, Poland, October 8-10 2018.