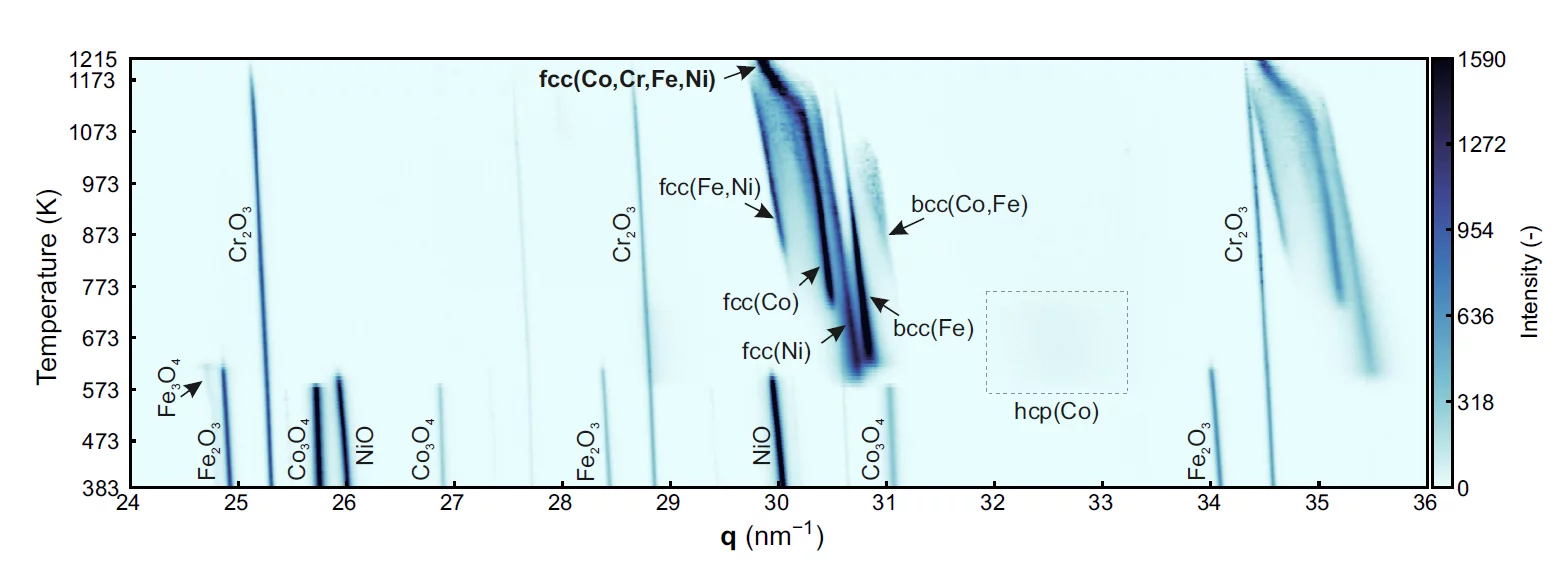

Additive manufacturing of high-entropy alloys combines the mechanical properties of this novel family of alloys with the geometrical freedom and complexity required by modern designs. An approach to additive manufacturing of high-entropy alloys has been developed based on 3D extrusion of inks containing a blend of oxide nanopowders (Co3O4 + Cr2O3 + Fe2O3 + NiO), followed by co-reduction to metals, inter-diffusion and sintering to near-full density CoCrFeNi in H2. A complex phase evolution path is observed by in-situ X-ray diffraction in extruded filaments: the oxide phases undergo reduction and the resulting metals inter-diffuse, ultimately forming the desired fcc-CoCrFeNi alloy (see figure). Linked to this phase evolution is a complex micro-structural one, from loosely packed oxide particles to fully-annealed, metallic CoCrFeNi with 99.6 ± 0.1% relative density. CoCrFeNi micro-lattices are created with strut diameters as low as 100 μm and excellent mechanical properties at ambient and cryogenic temperatures.

Contact

Dr Nicola Casati

Laboratory for Synchrotron Radiation - Condensed Matter Physics

Paul Scherrer Institute, 5232 Villigen, Switzerland

+41 56 310 5346

nicola.casati@psi.ch

Original Publication

3D ink-extrusion additive manufacturing of CoCrFeNi high-entropy alloy micro-lattices

Christoph Kenel, Nicola P.M. Casati, David C. Dunand

Nature Communications 10, 914 (2019), 22 February 2019

DOI: 10.1038/s41467-019-08763-4