The fuel used for nuclear energy production is normally enclosed in cladding tubes that constitute the first barrier between the radioactive material and the environment. In water-moderated reactors, the cladding tubes are directly in contact with the cooling water. One of the most common materials employed for nuclear fuels clad application is zirconium. Zirconium has high affinity with oxygen, and in aqueous environment tends to corrode, generating zirconium oxide and hydrogen as side product. At the temperatures typically faced by the cladding material, part of the hydrogen diffuses into the metal lattice, affecting the mechanical performances of the material. The study of the hydrogen embrittlement in zirconium alloys is of primary importance to help to guarantee the integrity of the nuclear fuel assemblies, from the energy production phase to the final storage at deep geological repositories.

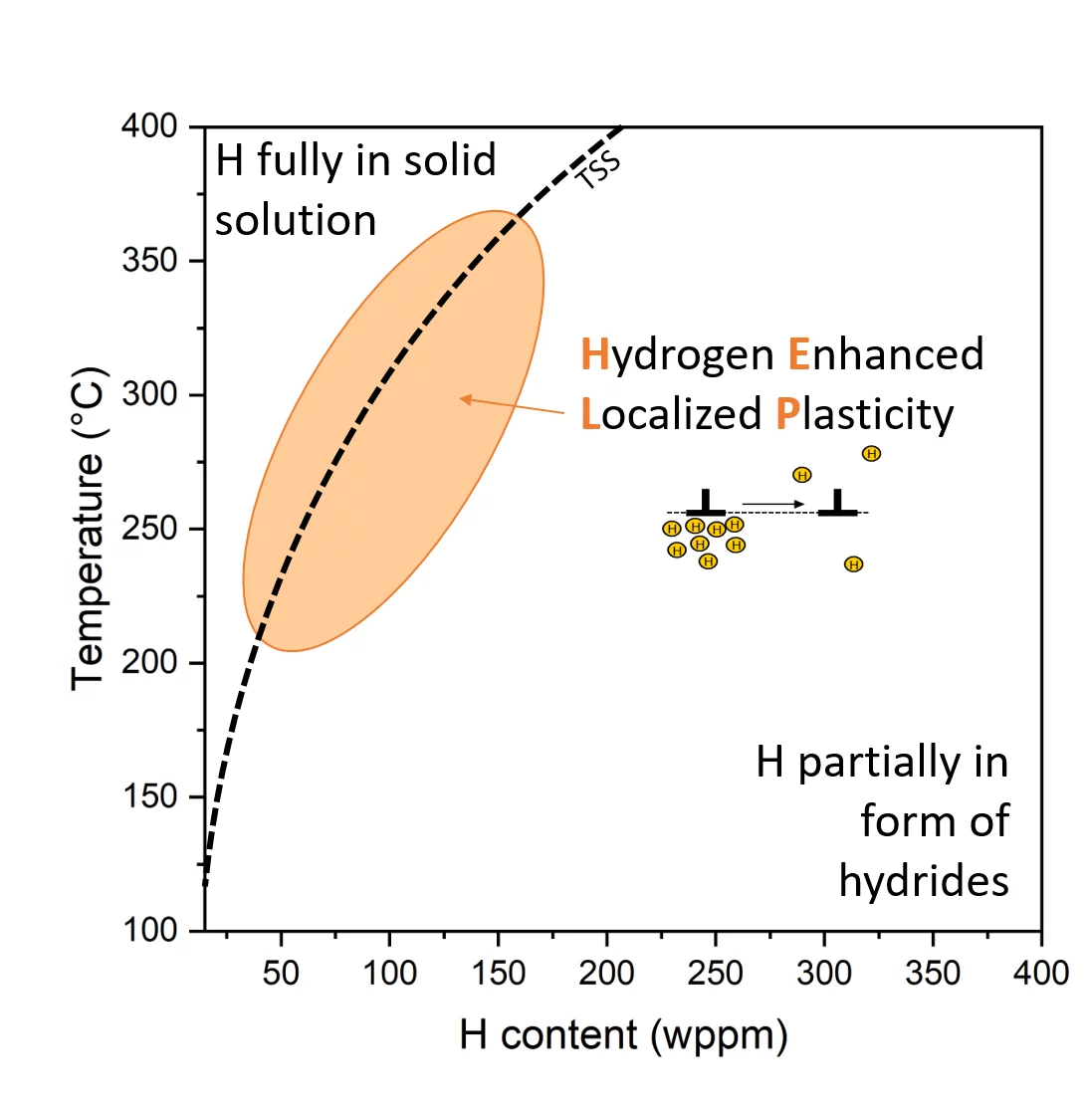

Depending on temperature, local hydrogen concentration, and local stress conditions, different hydrogen-induced embrittlement mechanisms can be active in the cladding material: at lower temperatures and higher hydrogen concentrations, hydrogen precipitates within the zirconium matrix forming zirconium hydrides, a brittle second phase. On the other hand, at higher temperatures and lower hydrogen concentrations, hydrogen can cause material softening through a mechanism known as hydrogen enhanced localized plasticity (HELP). Whereas the embrittlement effect caused by zirconium hydrides has been extensively studied in the past decades, the effect that hydrogen in solid solution has on the deformation mechanisms is still an open topic.

Within the HELP project at PSI, the mechanical properties of zirconium-based samples in presence of hydrogen in solid solution has been evaluated by micro-mechanical and micromechanical techniques such as elevated temperature strain rate analysis, elevated temperature micro-indentation and 3-point bending test at elevated temperatures.

Results highlight the importance of the interplay between solid solution hydrogen and hydrides on the hardness and yield point of the tested materials. Besides the well-known hydride-induced hardening effect, results indicate the presence of a small but significant hydrogen-induced softening effect in conditions where the majority of hydrogen is expected to be in solid solution. The most pronounced softening effect has been recorded at 300°C for samples enriched with 100 wppm of hydrogen. In those conditions, a decrease of 1% has been recorded by micro-hardness test and a decrease of 3% was recorded in flexural-yield stress of clad sections. The recorded softening effect might be attributed to the presence of hydrogen-induced plasticity compatibly with the HELP model.

Author

Francesco Fagnoni

francesco.fagnoni@psi.ch

phone: +41 56 310 5324

Nuclear Fuels, Laboratory for Nuclear Materials (LNM)

Original Publication

F. Fagnoni, A. W. Colldeweih, S. Binato, J. M. Wheeler, R. Spolenak, M. Wolff, J. Bertsch, L. I. Duarte (2022) Mechanical Behavior of Zircaloy-4 in the Presence of Hydrogen in Solid Solution at Elevated Temperatures

ASTM 20th International Symposium on Zirconium in the Nuclear Industry, 20.06.2022, in press.