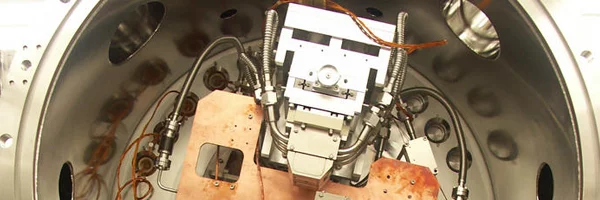

The microXAS beamline at the Swiss Light Source (SLS) corresponds to a versatile, in-vacuum undulator based hard x-ray microprobe facility. The beamline is covering the large spectral range from ~3keV up to ~23 keV, delivering monochromatic radiation as well as full ‘white’ light. Employing different focusing concepts, the beamline provides several types of high-brilliance focused beams, covering a large range of spatial resolutions from hundreds of micrometers down to nanometer size. The instrument is devoted to high resolution multimodal chemical imaging based on X-ray fluorescence, X-ray spectroscopy and X-ray diffraction techniques. The variety of complementary imaging modes can be employed routinely in quasi-simultaneous manner to record 2D images of several chemical properties. The progression of the imaging capabilities to full three dimensions using tomographic approaches is currently in progress.

Two additional features make the microXAS beamline a rather exceptional and exclusive X-ray microprobe facility. First, the microXAS beamline permits the investigation of radioactive materials and corresponds to the world-wide solely microprobe facility being able to analyze radioactive sample with 1µm spatial resolution. Second and definitely going beyond any existing X-ray microprobe instrumentation, the FEMTO project is an integral part of the microXAS beamline project. Ultrafast time-resolved X-ray studies with a resolution of picoseconds down to ~100 femtoseconds are ‘routinely’ carried out at the microXAS beam line.

Energy range | ~3 - 23 keV |

|---|---|

Flux on sample | 2 x 1012 ph/s/400 mA |

Spot size on sample± | 1 x 1 µm2 |

Polarization | linear horizontal |

Photon energy resolution | 0.02% |

Zinc detected in clogged syringes

With the help of researchers at PSI, ANAXAM has been investigating, on behalf of the pharmaceutical company MSD, whether zinc may contribute to clogging of pre-filled syringes.

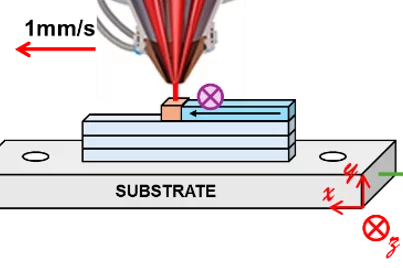

Phase by Phase: How Stainless Steel and IN625 Solidify Together

Where steel meets superalloy: real-time X-ray snapshots reveal how composition and cooling shape metal during 3D printing

Rescuing music with X-rays

SLS plays the King of the Blues – B.B. King! In collaboration with the Montreux Jazz Digital Project, historic audio tapes are being digitised at PSI.