The capillary reactor setup is available also for external users. It can be used to measure XAS/XES from samples inside a capillary in transmission and/or fluorescence modes at controlled conditions, such as temperature, pressure, gas or liquid flow through the sample. The highest temperature is limited to 800 oC

Typical applications

There are several options for using this setup:

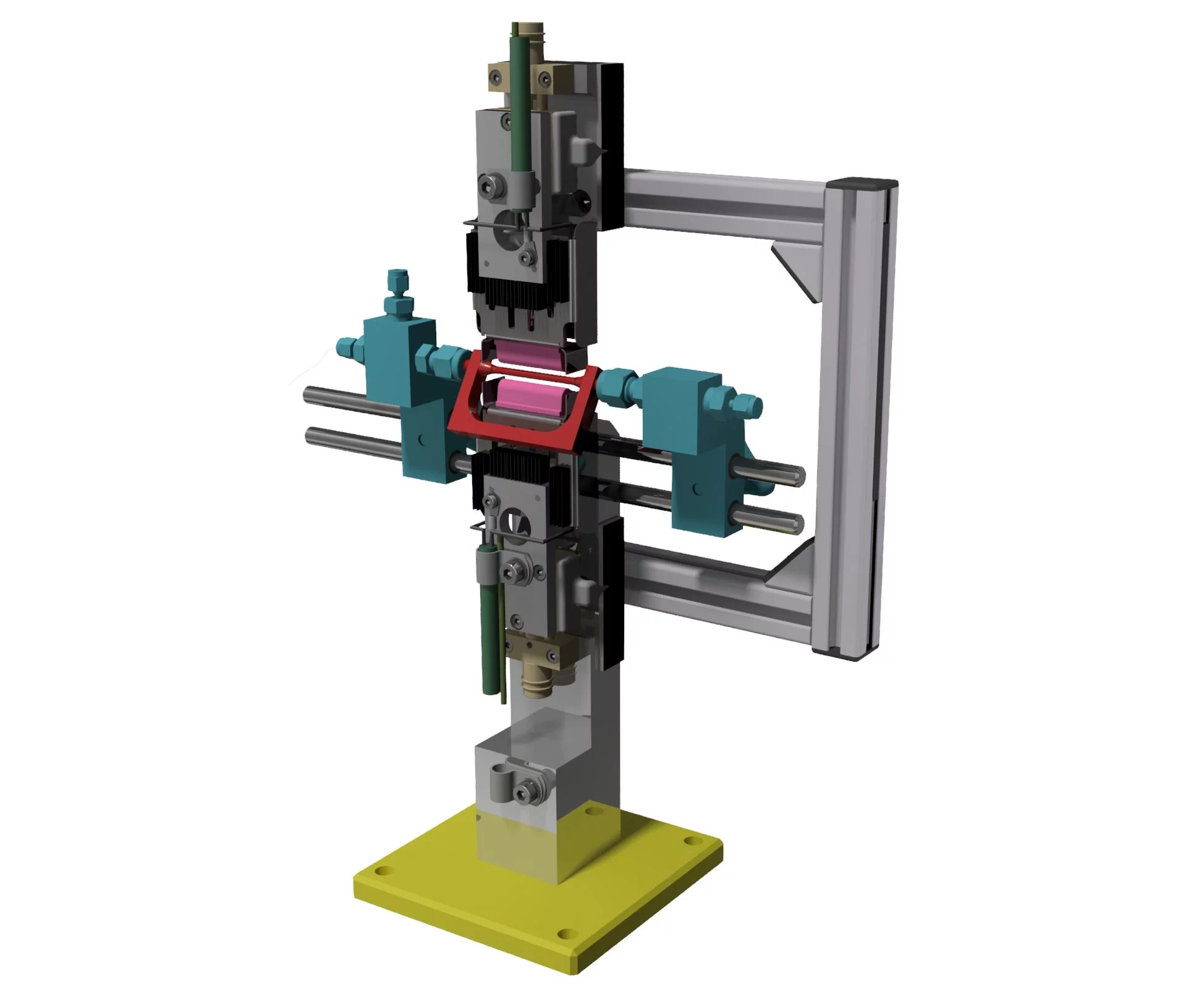

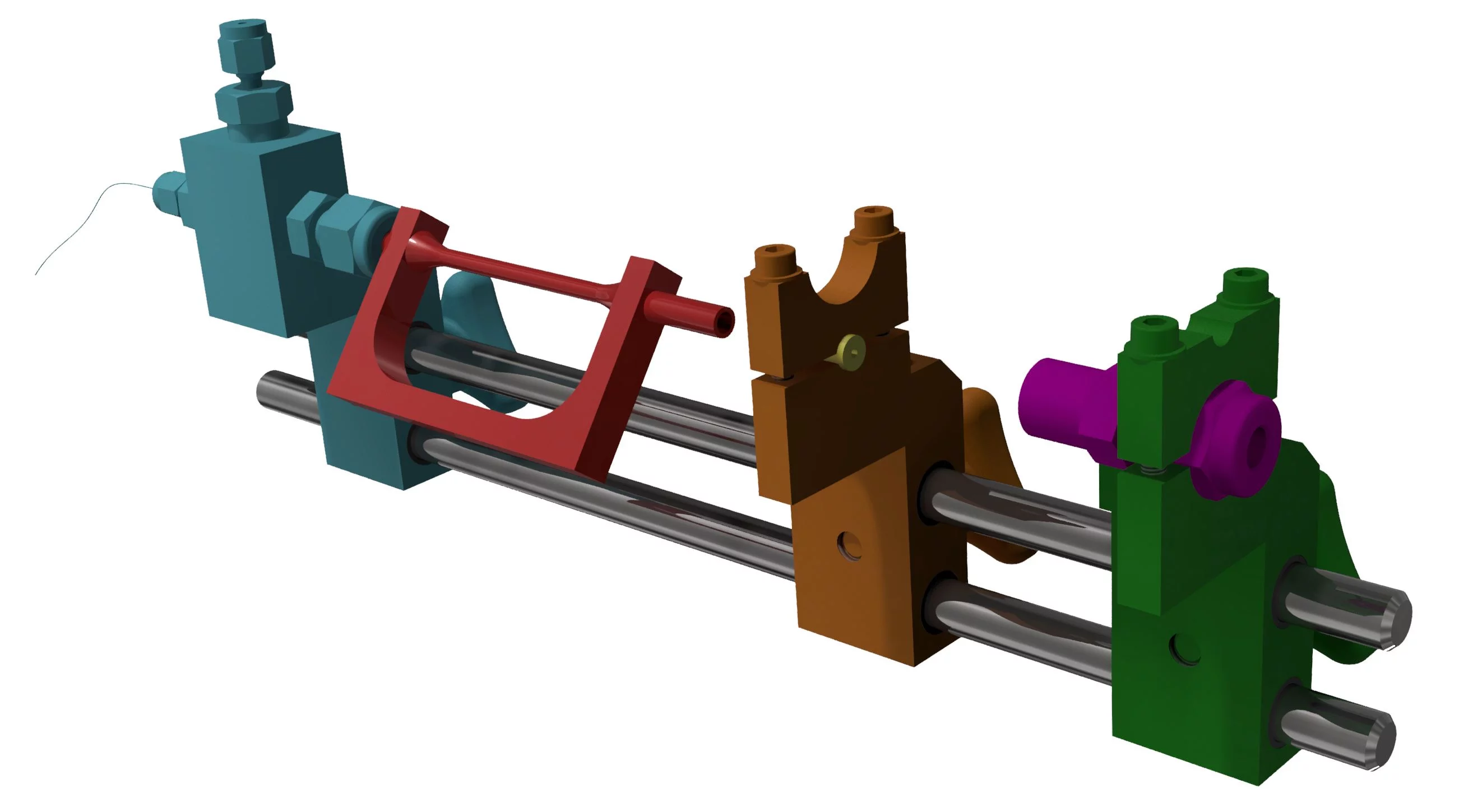

Option 1 (most common): the first option is for in situ and operando XAS/XRD catalytic experiments using capillary as a flow reactor. In this case, the capillary is filled in air with a sieved fraction of a catalyst powder, surrounded by quartz wool plugs, and glued with epoxy glue in U-shaped stainless steel frames (Figure 1 below shows in red a capillary mounted in a frame), making the quartz-metal connection tight against the leaks. The U-frame is then attached on both sides using 3/16" Swagelok fittings to the blue holders (Figure 1). One of the blue holders also brings a 0.35-0.5 mm stainless steel K-type thermocouple inside the capillary (the thermocouple is sealed with graphite ferrule on a 1/16" Swagelok connection). The catalyst bed should be no longer than 8 mm to ensure homogeneous heating. The heating elements in 30 mm long. Horizontally, the tip of the thermocouple should be no further than 8 mm from the center of the heater. U-frames are available in 3 sizes: i) with a 1.2 mm hole on one side and a 3.2 mm hole on the other side, for 0.8-1.0 mm OD non-cut capillaries; ii) with two 2.2 mm holes for 1.5-2 mm OD capillaries; and iii) with two 3.2 mm holes for 2.5-3 OD mm capillaries. The length of the gap in the U-frame is 60 mm. Choose capillaries of at least 70 mm long to fix them in U-frames. The capillaries are not provided by the beamline. They can be ordered from Hampton Research or Hilgenberg . We typically work with pre-cut or not 0.8-2 mm OD quartz capillaries with 10-20 micron walls or with 2-3 mm OD pre-cut quartz tubes with 50-100 micron walls. The use of pressure may put additional constraints on the choice of the capillaries. Discuss the best option for your experiment with beamline scientists.

Option 2: the second option is also for in situ and operando XAS/XES catalytic experiments using capillary as a flow reactor with a bypass, which allows filling samples air-free in a glove box and doing experiments without any exposure of material to air. In this case, the reactor is fixed with green holders (Figure 1) optimized for 3/16" Swagelok fittings. The same requirements are applied to capillaries, the catalyst bed, and the thermocouple. Discuss details with the beamline scientists.

Option 3: the third option is for heating sealed or open capillaries with a sample. The capillary is mounted in an orange holder inside the yellow tube (figure 1) and immobilized with a fixing paste. The second empty capillary with a thermocouple is fixed in front of the first one, to control the temperature.

Option 4 (not optimized): the holder can be used also to cool the sample down to 100 K with Cryostream setup. Discuss details with beamline scientists.

Heat and Control

Two infrared heaters (above and below the capillary) can heat capillaries up to a maximum temperature of 800°C, depending the size of the capillary, the gas flow through the sample, the distance between the heaters and the capillary or the air flow around the capillary. If you plan to use temperatures above 600°C, please contact the beamline staff to discuss your idea.

The optimal distance from capillary to heaters in 0.5-1 mm

The PID temperature controller controls both infrared heaters using the thermocouple inside the capillary as the reference temperature.

The manual of the capillary reactor is available below

Integration of setup

As visible in the picture below, the base plate (yellow) includes holes to mount the setup onto the sample manipulator of SuperXAS. By this, the setup can be aligned in all translational axis and rotated around the vertical axis.

If the standard U-frame mount is used, the connection to the gas supply and exhaust system is made with 1/16" Swagelok connectors.

The temperature can be controlled and logged online using Python based software.