X-ray Photoelectron Spectroscopy (XPS) has historically been carried out in ultra high vacuum (10-8-10-12 mbar) to prevent the inelastic scattering of photoelectrons

and to operate the electron analyzers (photoelectrons extraction, focusing and detection). This has created a pressure gap, and a series of limitations in the applicability of XPS as a technique

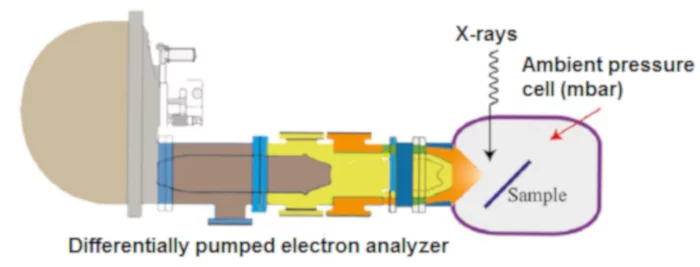

to characterize actual samples under relevant working conditions. The development of differentially pumped photoelectron spectrometers has allowed to partially fill this gap [1,2].

An aperture (titanium cone with aperture ranging from 0.1 to 1.0 mm) separates the experimental cell, where a gas/mixture of gases can be dosed in the mbar range, from the first differential pumping stage of the analyzer [3]. Two differential pumping stages (turbomolecular pumps) create a pressure drop from the mbar to high vacuum while pre-lenses extract and refocus the photoelectrons emitted from the sample. The third and fourth differential pumping stages create a stable high/ultrahigh vacuum in the lens, analyzer and detector regiorn. For example, while dosing 1 mbar of gas in the experimental cell, the pressure drops to 10-4-10-5 mbar in the first differential pumping stage and oscillates between 10-8 and 10-9 mbar in the detector. By means of Ambient Pressure X-ray Photoelectron Spectroscopy actual samples can be investigated in experimental conditions reproducing/mimicking the real ones.

The In Situ Spectroscopy Beamline

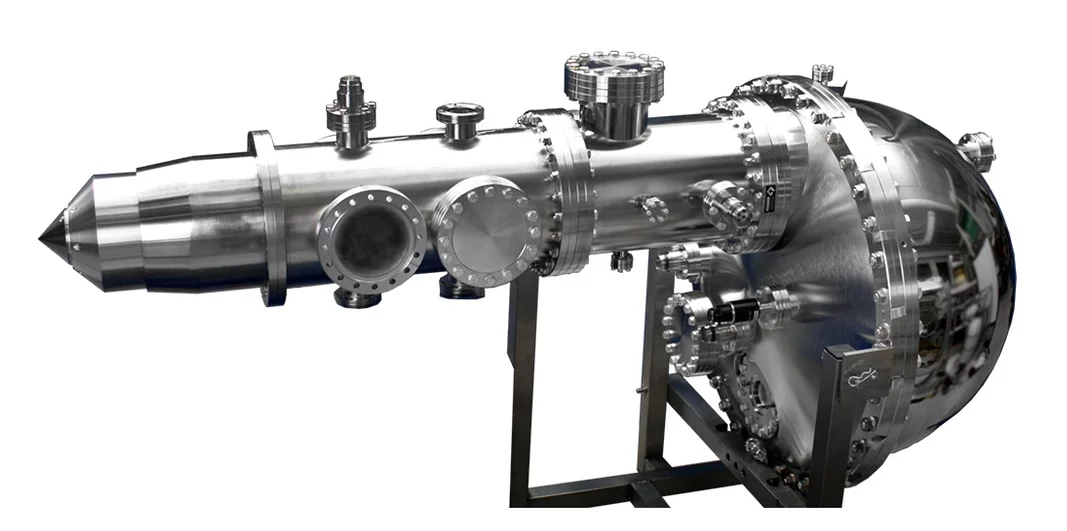

The In Situ Spectroscopy beamline is a modular system. The AP-electron analyzer is a ScientaOmicron R4000-Hipp-2 with four differential pumping stages.

The detector is a multichannel plate coupled with a CCD camera. Different titanium cones (different size of the aperture and focal distance) are available and can be chosen based on the experiment and on the experimental conditions. Photoemission spectra can be acquired in fixed (or snapshot) mode or in swept mode. Real-time processing of the experimental data is possible, loading the data in the scientific data analysis software. Two experimental chambers are available and can be connected to the electron analyzer:

- Solid-gas interface endstation. In-situ investigation/characterization of the solid-gas and of the solid-vapor interface. Catalysis, Environmental Chemistry, Surface Chemistry.

- Solid-liquid interface chamber. In-situ investigatio/characterization of the solid-liquid, of the solid-vapor and of the solid-gas interface. Electrochemistry, Electrocatalysis, Environmental Chemistry, Catalysis, Surface Science.

References

[1] M. Salmeron, R. Schloegl, Surf. Sci. Rep. 2008, 63, 169-199.[2] D. E. Starr, Z. Liu, M. Hävecker, A. Knop-Gericke, H. Bluhm, Chem. Soc. Rev. 2013, 42, 5833-5857.

[3] K. Roy, L. Artiglia, J. A. van Bokhoven ChemCatChem 2018, 10, 662-682.