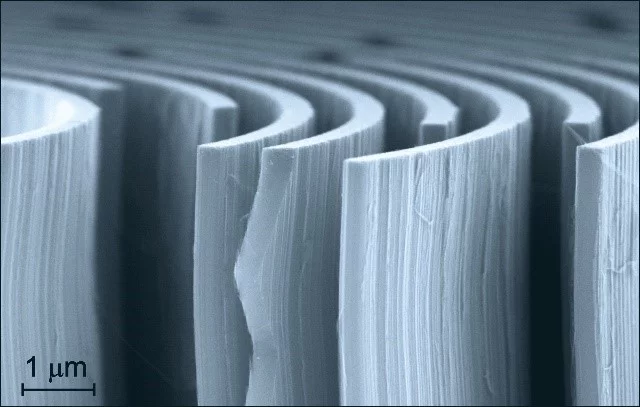

What is the difference between microfabrication and nanotechnology? Scientists struggle all around the world to scale down device feature size by top-down techniques such as plasma etching with specialized cryogenic gases and electrode design. On the other hand, a bottom-up approach is a natural and cost-effective choice of nanofabrication. In this regard, Metal assisted chemical Etching (MacEtch) bypasses the limits of aspect ratio with a local electrochemical reaction that occurs only at the nanoscale of the catalyst surface. At PSI, the grating fabrication team of the X-ray tomography group proposed the concept of inducing the MacEtch reaction in the gas phase in order to promote MacEtch among the dry etching techniques. The new method allows vertical etching with the extreme aspect ratio of 10 000 : 1 and feature size down to 10 nm with high precision and control of pattern transfer into the silicon substrate. Such capability opens a new world of possibilities for nanofabrication. As a proof-of-concept, the team successfully etched patterned structures for X-ray optics, where the control of feature size, roughness and precision of pattern transfer are fundamental for the performances of the application.

MacEtch in gas phase: a new nanofabrication technology at PSI

Romano, L., Kagias, M., Vila-Comamala, J., Jefimovs, K., Tseng, L. T., Guzenko, V. A., & Stampanoni, M.

Nanoscale Horizons, 5(5), 869-879 (2020).

Senior Scientist, Swiss Light Source

Paul Scherrer Institut

Telephone: +41 56 310 56 88

E-mail: lucia.romano@psi.ch