Die EPMA ist ein Instrument zur hochauflösenden Oberflächenuntersuchung von festen Materialien und nutzt zwei Detektionsmethoden aus der Wechselwirkung eines hochenergetischen Elektronenstrahls mit der Probe – hochauflösende Oberflächenabbildung und quantitative Punktanalyse der Elementzusammensetzung.

Diese Methoden sind wie folgt spezifiziert:

Rasterelektronenmikroskopie (REM)

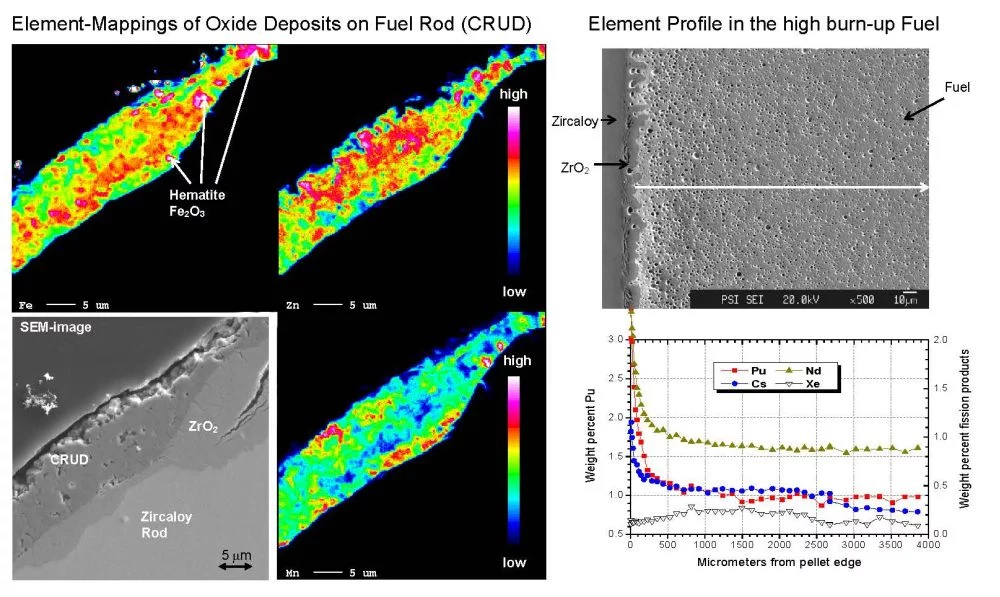

- Oberflächenabtastung mit einem Elektronenstrahl und Detektion von Sekundärelektronen (fotografisches Elektronenbild der Oberfläche).

- Darstellung der Topographie und Morphologie von Proben mit einer Vergrößerung von 40- bis 100.000-fach bei großer Tiefenschärfe.

- Rückstreuelektronendetektor (BSE) für den kontrastreichen Phasenvergleich der Zusammensetzung.

Röntgen-Mikroanalyse mit wellenlängendispersiver Spektroskopie (WDS)

- Quantitative Elementaranalyse von polierten Oberflächen in einem Mikrobereich von typischerweise 0,2 bis 2 µm³ bis zu Elementkonzentrationen von 0,1 Gewichtsprozent (Nachweisgrenze etwa 100 ppm) durch Messung der Emission von Röntgenstrahlen aus dem angeregten Zustand der Atome.

- Analysebereiche bis zu einem Durchmesser von 60 µm durch Defokussierung des Strahls.

- Elementverteilungsmapping von Oberflächen durch Strahl- und Bühnenabtastung.

Instrument

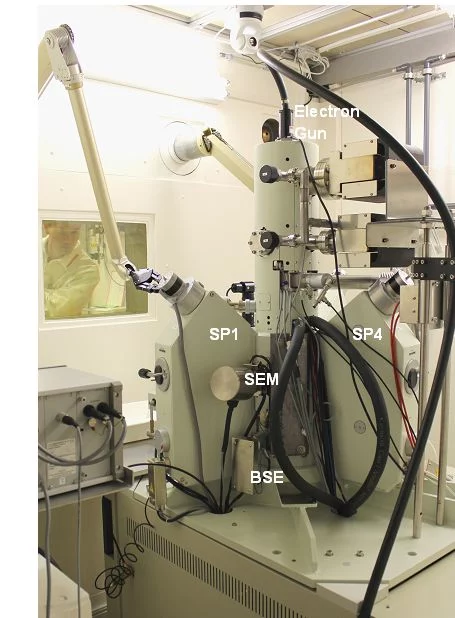

- JEOL 8500F mit Feldemissionskanone (FEG) mit hoher Helligkeit und kleinem Elektronenstrahldurchmesser.

- Hochenergetischer Elektronenstrahl (1–30 keV) und Stromstärken von 0,01 – 500 nA.

- Das Instrument befindet sich in einer bleigeschirmten Kabine, getrennt von der Steuerkonsole.

- Massive interne Wolframabschirmung zum Schutz der Röntgenzähl-Detektoren, um auch hochradioaktive Proben messen zu können.

- Vier Röntgenspektrometer (SP1 – SP4), zwei mit PET/LIF-Analysenkristallen, LD1/TAP und LD2/TAP für leichte Elemente.

- Zwei Probenträger für Proben bis zu einer Größe von 1¼-Zoll: ein geschirmter Halter für quantitative Analysen und ein Halter für die Kipp- und Rotationsbühne (z. B. für Bruchflächenuntersuchungen).

Anwendungsbereich

- REM- und BSE-mikroskopische Abbildung von Oberflächen.

- Quantitative Elementanalyse durch Röntgenstrahlen (Punktanalyse, Linienanalyse).

- Qualitatives und semi-quantitatives Elementmapping mit hoher Vergrößerung (lokale Strahlabtastung) oder großflächiger Bühnenabtastung (bis zu 20 x 20 mm²).