Projekt BALDER an der RRFM-2025

Auf der diesjährigen Europäischen Konferenz für Forschungsreaktoren (RRFM-2025) in Aix-en-Provence stiess die Präsentation des BALDER-Projekts auf großes internationales Interesse.

Erfolgreiche Präparation zur Gefüge-Darstellung in Zircaloy-4 mittels Lichtmikroskopie

Erfolgreiche Präparation zur Gefüge-Darstellung in Zircaloy-4 mittels Lichtmikroskopie

Qualität gesichert – Erfolgreiche ISO 9001-Rezertifizierung

Qualität ist kein Zufall, sondern das Ergebnis konsequenter Arbeit – unser Unternehmen hat das Rezertifizierungsaudit nach ISO 9001 erneut mit Bravour bestanden!

Le Laboratoire Chaud a 60 ans

En Suisse, l’installation nucléaire en service depuis le plus longtemps se trouve à l’Institut Paul Scherrer PSI. Elle fête son anniversaire aujourd’hui.

Jubiläumsfeier 60 Jahre Hotlabor

Seit 60 Jahren steht das Schweizer Hotlabor für Spitzenforschung und technologische Innovation. Am 26. September 2024 wurde dieses beeindruckende Jubiläum mit einem Festakt in Villigen gefeiert.

Précision unique: nouvelle valeur pour la demi-vie du samarium-146

Des scientifiques du PSI et de l’Université nationale australienne ont déterminé la demi-vie du samarium 146 avec une très grande précision.

Coopération dans le domaine des réacteurs

Copenhagen Atomics et l'Institut Paul Scherrer PSI ont conclu un accord de coopération portant sur une collaboration expérimentale de grande envergure.

Forensics: Quantitative tracing of Silicon in CRUD

Chalk River Unidentified Deposits (CRUD) are dissolved and suspended solids, product of the corrosion of structural elements in water circuits of nuclear reactors.

The chemical composition of CRUD is variable as it depends on the composition of the reactor’s structural material, as well as the types of refueling cycles. Recent internal investigations have found unexpected but significant Si-amount in CRUD. The chemical composition of CRUD holds key information for an improved understanding of CRUD formation and possible impact in fuel reliability and contamination prevention.

The standard analytical methods available in the hot laboratory did not allow an easy quantitative determination of the Si-amount in CRUD. A new innovative procedure has been developed and tested with synthetic CRUD name Syntcrud.

The adapted flex-fusion digestion method presented here is able to provide reliable concentrations of several elements within CRUD, including Si, which was not possible in methods used previously for ICPMS measurement.

A unique environment for research on highly radioactive materials

PSI has a unique (worldwide) environment for the investigation of highly radioactive / toxic materials:

> Materials (different fuel types, very high burn-up, different cladding materials, materials activated in SINQ).

> The hot lab with advanced tools for microsample analysis and preparation.

> The large-scale equipment for advanced material analysis.

This unique combination at PSI allows us to meet the needs of our industrial partners to improve plant safety / efficiency, up to fundamental research.

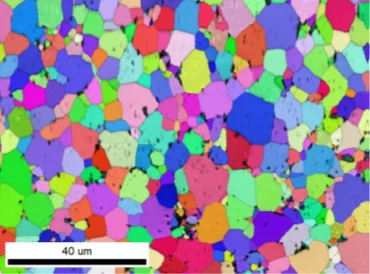

The quantitative distribution of fission products over the cross-section of a pellet with a shielded electron probe microanalyzer (EPMA) used for verification analysis of the material behavior to validate the model. In this context, Xe behavior during transients/failure (LOCA, RIA) is an important safety parameter that can’t be measured with the EPMA at the periphery. Microstructural EBSD investigations on a microsample extend the information horizon, which is deepened at the microXAS beamline by detailed X-ray analyses.

Hydrogen-induced softening effect in zirconium alloys

The fuel used for nuclear energy production is normally enclosed in zirconium-based cladding tubes that constitute the first barrier between the radioactive material and the environment. In water-moderated reactors, cladding tubes tend to corrode, generating hydrogen as side product. The study of the hydrogen embrittlement in zirconium alloys is of high relevance for the industry.

Depending on temperature, local hydrogen concentration, and local stress conditions, different hydrogen-induced embrittlement mechanisms can be active in the cladding material: in certain conditions hydrogen in solid solution might cause material softening through a mechanism known as hydrogen enhanced localized plasticity (HELP).

With the goal of determining the conditions necessary to activate the HELP effect in zirconium alloys, samples have been evaluated by different micro-mechanical and macro-mechanical techniques. Results highlight the importance of the interplay between solid solution hydrogen and hydrides on the hardness and yield point of the tested materials.

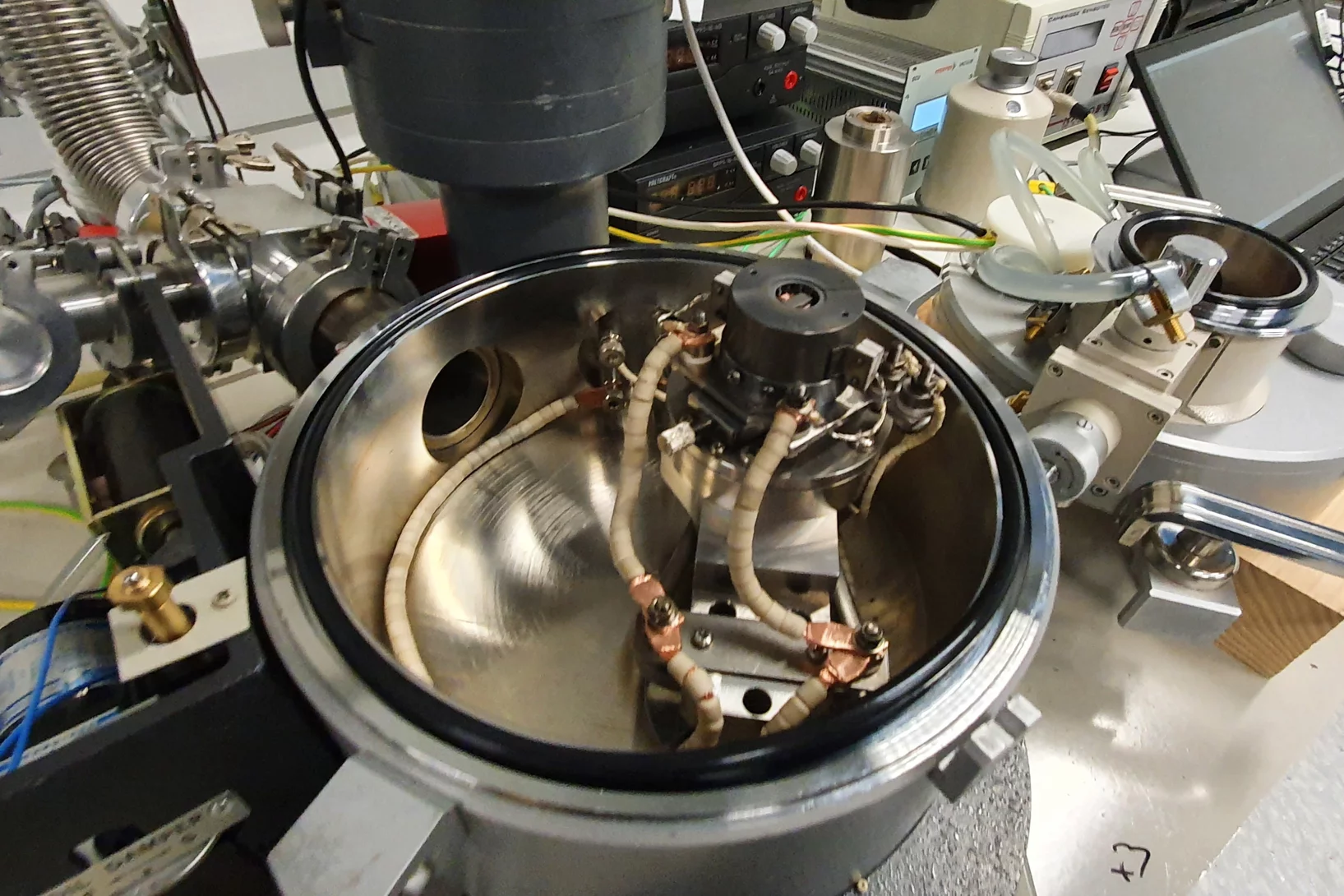

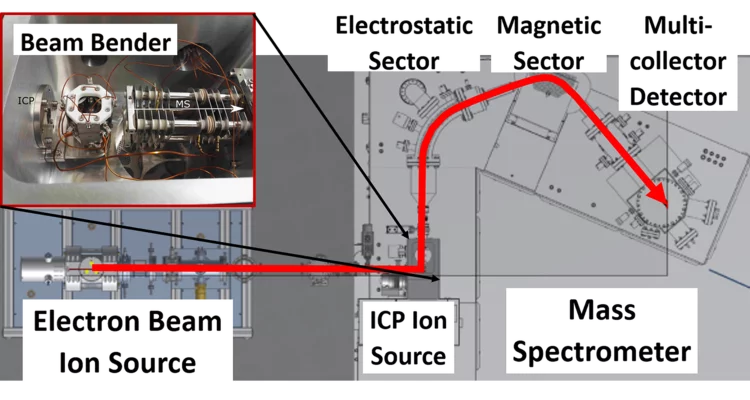

MC-EBIS-ICP-MS – a unique dual Ion Source Mass Spectrometer

This highlight presents a successful, in-house developed integration of an Electron Beam Ion Source (EBIS) able to ionize gases to high charge states with a customized commercial MC-ICP-MS. The successful joining of the two ion flight paths is a milestone towards comprehensive routine analyses of solids, liquids, and gases using THE SAME MASS SPECTROMETER, the latter analyses free from atmospheric contamination. After implementation of an introduction system for gas mass spectrometry, routine analyses will comprise isotope ratio and relative abundance determinations of fission gases in used nuclear fuel. In addition to the unique versatility of the MC-EBIS-ICP-MS, inclusion of the EBIS furthers opens the little-studied field of mass spectrometry of highly charged ions.

Bestätigte Qualität – Erfolgreiche ISO 9001-Rezertifizierung

Qualität ist unser Anspruch – und die erfolgreiche ISO 9001-Rezertifizierung zeigt, dass wir diesem gerecht werden!

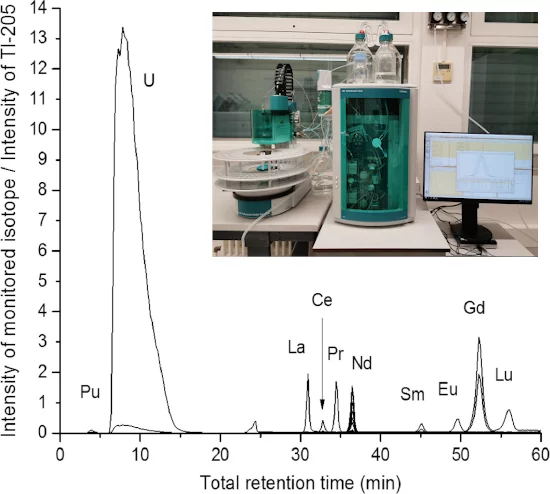

New element and speciation specific analytical options at AHL

The Hot Laboratory division (AHL) within PSI’s Nuclear Energy and Safety (NES) division continually upgrades and advances its analytical infrastructure to provide cutting-edge scientific service to PSI’s researchers and industrial customers. A new, fully automatable and highly flexible Ion Chromatograph (IC) furthers AHL’s efforts in sample miniaturization and extends the spectrum of destructive analytical capabilities to element and speciation specific analyses. With the new IC and its modern ICP-MS (Inductively Coupled Plasma Mass Spectrometry) facilities, AHL offers innovative scientific options for nuclear and general research. Moreover, speciation analyses by IC-ICP-MS for polyvalent inorganic water pollutants such as Cr or As and the acquisition of a new ICP-OES system (Inductively Coupled Plasma Optical Emission Spectrometry) enable future autonomy in wastewater management.

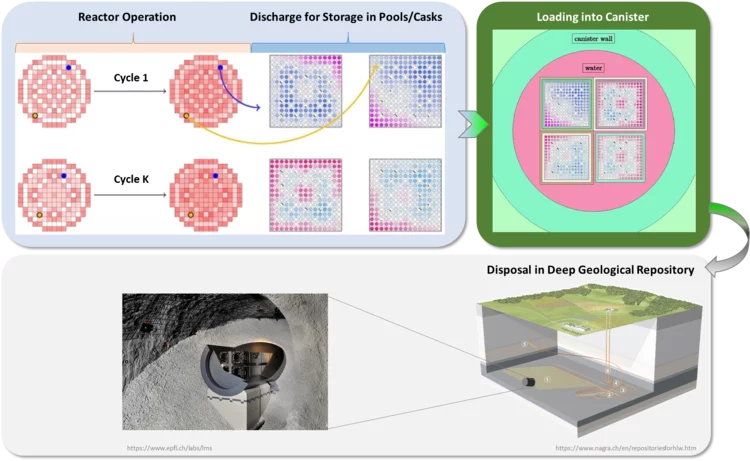

Used Nuclear Fuel: from Better Characterization to Better Optimization

A safe, economical and environmental friendly disposal of used nuclear fuel represents an essential objective of relevance for all. This guides the approach under development at the laboratory for reactor physics and thermal-hydraulics. Establish higher resolution simulation methods to gain more detailed knowledge on the content of each single nuclear fuel rod ever irradiated in a reactor. Thereafter, use this knowledge to explore optimization approaches that could potentially enlarge the range of disposal options allowing to fulfill the highest level of safety standards while reducing economical costs and geological footprints at the same time.

Hydrogen uptake into Zr-based fuel claddings

At the hot surface of a fuel rod cladding in the reactor water, the water is partially dissociated in hydrogen and oxygen, leading to corrosion of the cladding and to the uptake of a part of the created hydrogen. Hydrogen in solid solution and in precipitated form changes the mechanical properties of the cladding tube. The uptake of the hydrogen through the dense oxide layer is unclear. The structure and physical properties of the oxide near the metal-interface is critical The resistivity of the oxide increases with distance from the interface. Nb-containing alloys show lower resistivity in the oxide close to the metal interface, and exhibit a lower hydrogen pick-up. The time in the reactor is an important factor, leading to increasing resistivity in the oxide close to the metal interface, and a higher hydrogen uptake late in life.

Relevance of the findings: considering resistivity, the model of hydrogen uptake is better understood, revealing hints for further cladding development.

Les gaines de crayons combustibles et leurs propriétés

Johannes Bertsch travaille au PSI dans la division de recherche Energie nucléaire et sûreté, où il étudie les gaines qui enrobent le combustible exploité dans les centrales nucléaires.

Neue Betriebsbewilligung

Am 21. Februar 2019 erteilte das Eidgenössische Departement für Umwelt, Verkehr, Energie und Kommunikation (UVEK) die neue Betriebsbewilligung für die Anlage PSI Hotlabor

ISO 9001-Rezertifizierung bestanden – Qualität auf höchstem Niveau

Auch dieses Jahr wurde unser Qualitätsmanagement geprüft – mit Erfolg! Unsere ISO 9001-Zertifizierung bleibt bestehen.

Das Verhalten von UO₂-Brennstoff bei sehr hohem Abbrand

Die Untersuchung von Kernbrennstoff bei sehr hohem Abbrand ist entscheidend für die Bewertung der Sicherheitsmarge des untersuchten Brennstoffs sowohl unter normalen als auch unter Unfallbedingungen. Das PSI ist eines der wenigen heißen Labore, die Zugang zu bestrahltem UO₂-Brennstoff mit sehr hohem Abbrand aus kommerziellen Reaktoren haben. Der Einsatz relevanter Werkzeuge zur Untersuchung, Handhabung und Analyse dieser hoch bestrahlten Materialien unterstreicht die erforderliche Expertise.

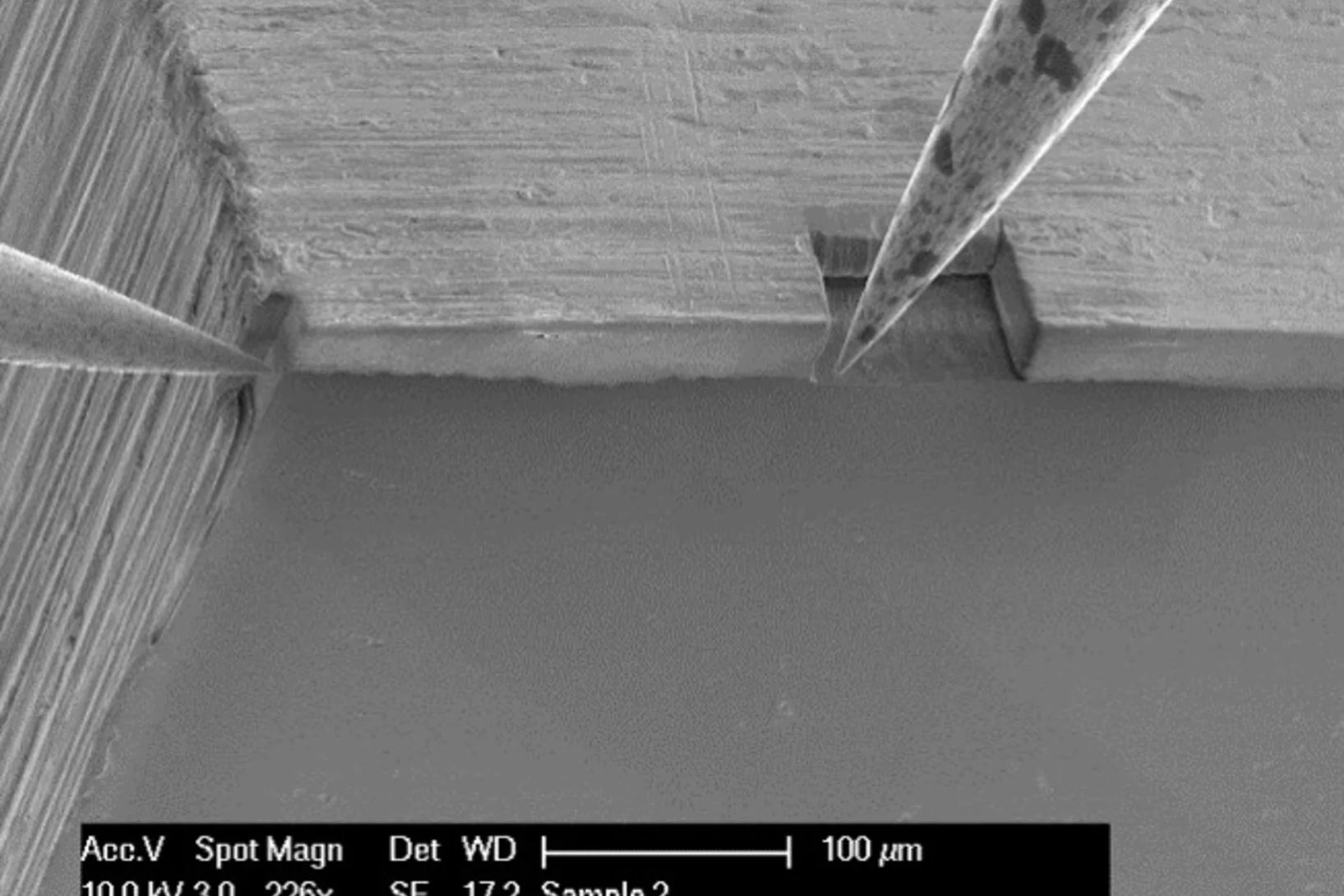

Neuer fokussierter Ionenstrahl (FIB) im Hotlabor

Die Implementierung von fokussierten Ionenstrahl-(FIB)-Instrumenten in Materialforschungslaboren im letzten Jahrzehnt hat nicht nur die Präparation sehr dünner Proben für das Transmissionselektronenmikroskop (TEM), insbesondere an Grenzflächen, erheblich verbessert, sondern auch zur Entwicklung neuer Analysemethoden direkt im Instrument selbst geführt. Es hat sich zu einem leistungsstarken Instrument für die Analyse hochradioaktiver Materialien entwickelt, da es die Herstellung und Untersuchung sehr kleiner Proben ermöglicht, die anschließend mit hochsensiblen Detektoren analysiert werden können, ohne dass es zu starken Störungen durch das Strahlungsfeld der Probe selbst kommt.

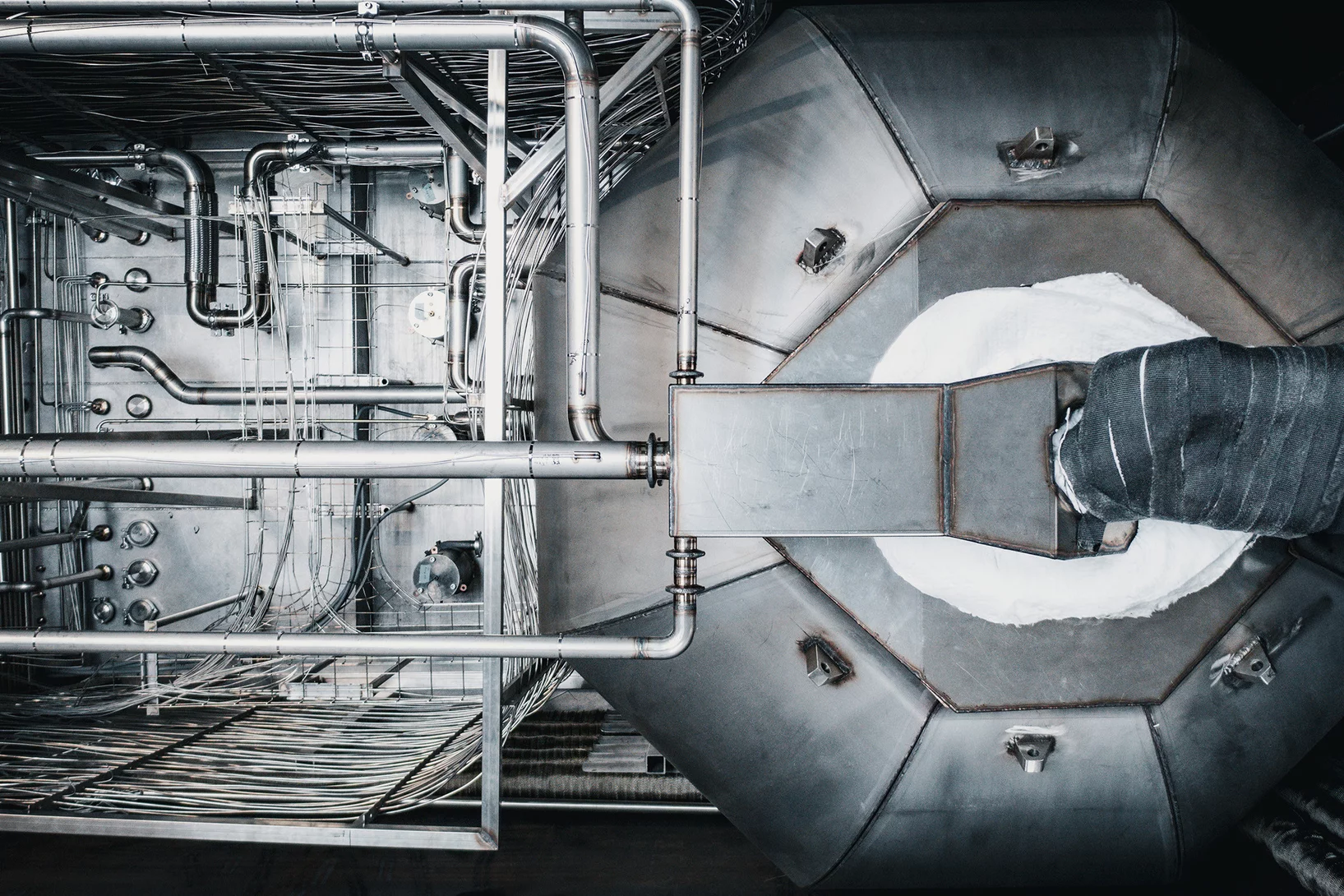

Sanierung der HZ6

Die Hotzelle 6 ist für die Lagerung und Konditionierung hochradioaktiver fester Abfälle vorgesehen. Diese Zelle wurde im Zeitraum von 2015 bis 2017 vollständig saniert. Dies umfasste den vollständigen Rückbau und die Konditionierung der stark mit Brennstoff kontaminierten alten Infrastruktur, die Reinigung der Zelle sowie die Installation und Erprobung der neuen, verbesserten Infrastruktur.

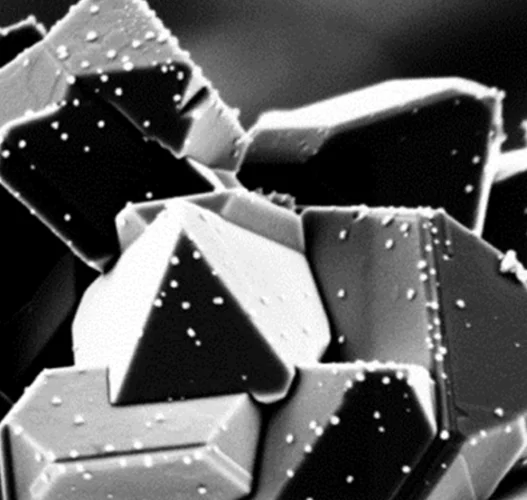

Pt nanoparticles: The key to improved stress corrosion cracking mitigation in boiling water reactors

The formation and growth of cracks by stress corrosion cracking (SCC)in reactor internals and recirculation pipes due to the highly oxidising environment is a serious issue in boiling water reactors. At first, SCC mitigation was attempted by injecting H2 into the feed water, where the injected H2 recombines with the H2O2 and O2 to water and reduces the electrochemical corrosion potential, and consequently the SCC susceptibility. Several disadvantages of the injection of high amounts of H2, have led to the development of noble metal additions to the reactor feed water. With injection of a much smaller amount of H2, the noble metal particles of a few nanometres in size, formed in-situ, work as catalysts for the efficient reduction of the oxidizing species formed by radiolysis, and thus lower the ECP and SCC susceptibility.

Neue Software für Proben- und Aufgabenmanagement

Das AHL verwaltet gemäß internen sowie externen Vorschriften Kernmaterialien und Moderatoren. Zur Erfassung und Kontrolle von Kernbrennstoffproben sowie zur Überwachung im Hinblick auf die Kritikalitätssicherheit hat das AHL eine neue Proben- und Aufgabenmanagement-Software (IPV) entwickelt.

Neues Abwasserreinigungssystem und Tanklager

Das PSI Hotlabor sammelt und reinigt radiologisch das gesamte radioaktive Abwasser der Ostseite des PSI. In den Jahren 2014–2016 fand eine umfassende Sanierung statt, bei der das alte Tanklager stillgelegt und neue Edelstahltanks zusammen mit modernen Ultrafiltrationssystemen während des normalen Laborbetriebs installiert wurden.

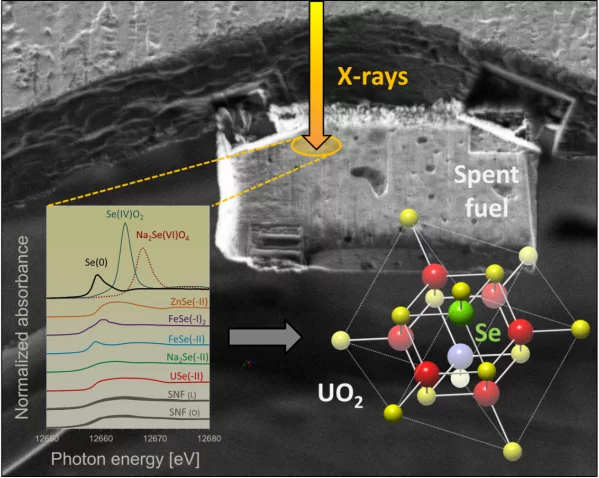

The chemical state of 79Se in spent nuclear fuel

An interdisciplinary study conducted at different PSI laboratories (LES, AHL, LRS, SYN) in collaboration with Studsvik AB (Sweden) demonstrates that selenium originating from fission in light water reactors is tightly bound in the crystal lattice of UO2. This finding has positive consequences for the safety assessment of high-level radioactive waste repository planned in Switzerland, as it implies (contrary to previous assumptions) that the safety-relevant radionuclide 79Se will be released at extremely low rates during aqueous corrosion of the waste in a deep-seated repository.

L'installation de recherche du Laboratoire chaud

Démarrage de l'enquête publique relative à une actualisation de l'autorisation d'exploitation de l'installation de recherche du Laboratoire chaud de l’Institut Paul Scherrer PSILe Laboratoire chaud de l’Institut Paul Scherrer PSI est une installation au sein de laquelle des chercheurs et chercheuses étudient les matériaux hautement radioactifs dans des enceintes blindées spéciales, également baptisées cellules chaudes. Cette installation est unique en Suisse. Elle sert la recherche appliquée sur les matériaux en analysant des échantillons hautement radioactifs de barreaux de combustibles et de matériaux de structure provenant de centrales nucléaires, de réacteurs de recherche et de l'accélérateur de proton du PSI. Grâce aux travaux du Laboratoire chaud, l’Institut Paul Scherrer contribue ainsi à la sécurité des centrales nucléaires suisses. Près de 32 salariés travaillent au sein de l'infrastructure spécialisée dans les techniques de sécurité et d'analyses du Laboratoire chaud.

Geprüfte Qualität – ISO 9001-Rezertifizierung erfolgreich abgeschlossen

Qualität, die überzeugt: Unser Unternehmen hat das ISO 9001-Rezertifizierungsaudit mit Bravour bestanden!

50 Jahre heisser Betrieb

50 Jahre Spitzenforschung im Schweizer Hotlabor: Am 26. September 2014 wurde dieses beeindruckende Jubiläum in Hotwil mit aktuellen und ehemaligen Mitarbeitenden feierlich begangen.

L’hydrogène: un cheval de Troie dans la gaine du crayon combustible

Dans un réacteur nucléaire, l’eau se sépare en oxygène et en hydrogène au contact de la gaine contenant les pastilles de combustible, alors à haute température. Cet hydrogène peut pénétrer dans la gaine qui enrobe le combustible proprement dit, et la fragiliser mécaniquement. A l’aide de neutrons et de rayonnement synchrotron, des chercheurs de l’Institut Paul Scherrer (PSI) étudient le mécanisme de pénétration de l’hydrogène dans la gaine et l’effet qu’il peut y déployer.

Des billes pour moins de déchets nucléaires

L’idée de produire du combustible nucléaire sous forme de sphères (et non de pastilles, comme c’est l’usage aujourd’hui) remonte aux années 1960. Les avantages suivants en étaient escomptés : une simplification de la fabrication du combustible ainsi qu’une nette réduction de la quantité de déchets radioactifs lors de sa fabrication et de son utilisation en centrale nucléaire. Ce type de combustible n'a toutefois jamais été utilisé parce que les types de réacteurs pour lesquels il avait été envisagé n’ont pas pu s'imposer. Dans le passé, l’Institut Paul Scherrer (PSI) a aussi contribué à la recherche en matière de combustible à particules sphériques. A nouveau, plusieurs projets, en partie financés par l’Union européenne, sont actuellement en cours au PSI. Leur objectif : continuer à améliorer la production des billes de combustible. Cette forme de combustible pourrait être utilisée soit dans des installations spéciales de réduction des quantités de déchets radioactifs, soit dans des réacteurs rapides de quatrième génération, qui, en cycle fermé, produisent eux aussi moins de déchets à vie longue.