When growing thin films of novel materials, smooth surfaces are a must. How else could one stack them layer by layer, as needed in optical coatings, sensors or conductors? One method known to produce atomically smooth films is Pulsed Laser Deposition (PLD).

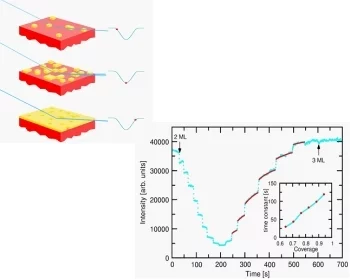

In PLD, a pulsed laser beam hits a bulk target. With every pulse, it creates a jet (or “plume”) of high energy atoms from the target. When these condense on a smooth substrate, they recreate the target material, but now as a thin film. Per laser pulse only about 1/100th of an atomic layer is deposited on the substrate.

Although the fact that PLD produces atomically smooth films has long been known, the reasons for this were somewhat speculative. A recent experiment measured the roughness of PLD films, carefully adding one laser pulse after another. This provided the clue to the puzzle: when the first atoms land on the smooth substrate they form small islands of the material. Subsequent pulses lead either to formation of more small islands if the particles land on an uncovered part of the monolayer, or, importantly, cause already formed islands to break up if the energetic particles land on top of them. This avoids growth of "islands on top of islands", which would gradually result in rough films - that is, atomic sandpaper. Now that the process is understood, one can optimally tune PLD for growing thin films of materials which are then used in devices.

Read full article

Read full article

Facility: SLS

Energetic smoothing studies of complex metal-oxide thin films P.R. Willmott, R. Herger, C.M. Schlepuetz, D. Martoccia, and B.D. Patterson, Phys. Rev. Lett. 96, 176102 (2006)

Energetic smoothing studies of complex metal-oxide thin films P.R. Willmott, R. Herger, C.M. Schlepuetz, D. Martoccia, and B.D. Patterson, Phys. Rev. Lett. 96, 176102 (2006)