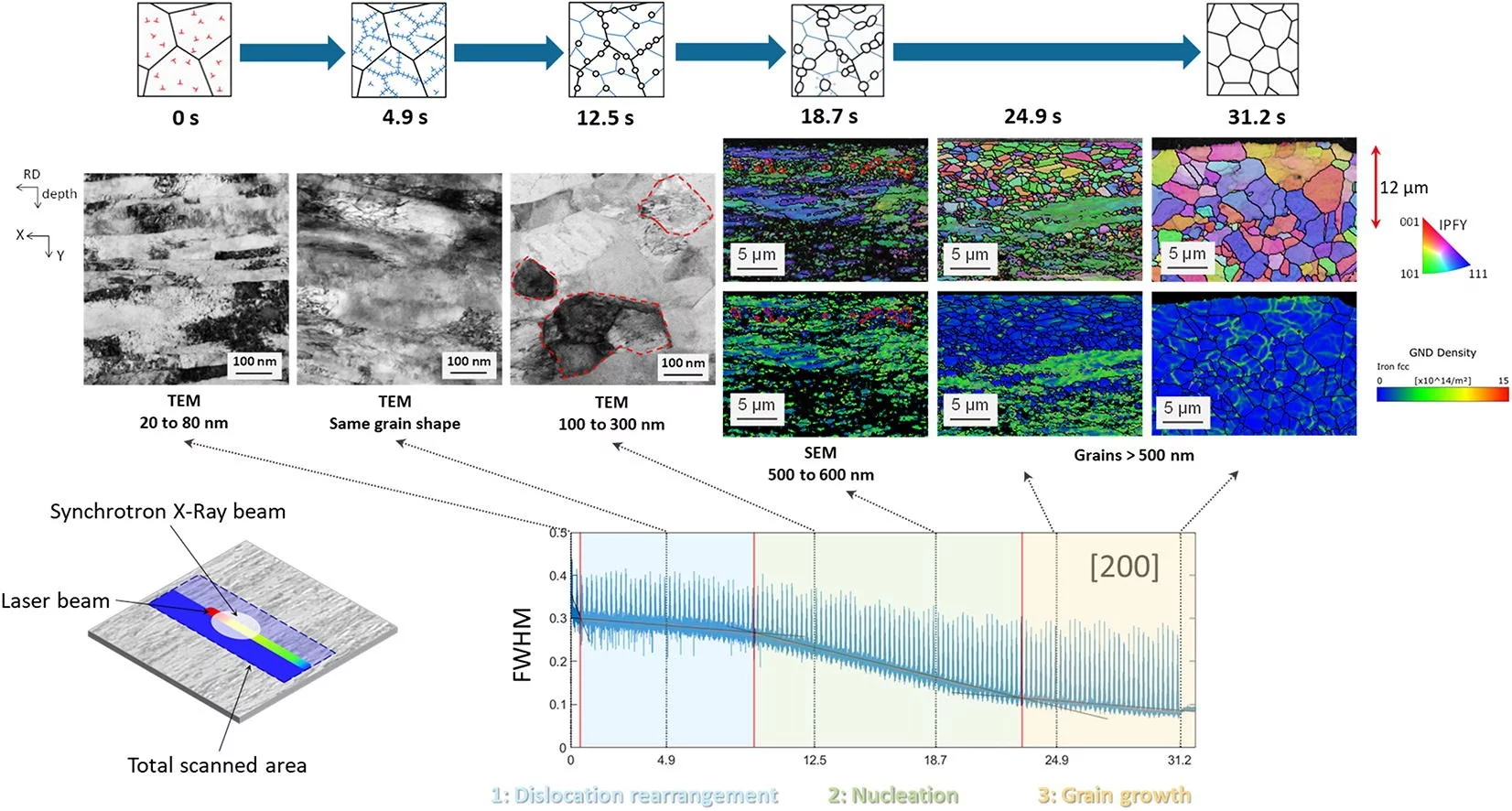

We present a new method to induce local recrystallization based on a selective laser-based heat treatment technique. The successive stages of recrystallization are studied by in situ X-ray diffraction combined with electron microscopy observations. This work paves the way for local tailoring of microstructures using laser treatments.

Grain refinement of metal structures is an extensively used method for improving mechanical properties of multiple alloys (and steels in particular), since most of the parts generated from casting or laser-based additive manufacturing (LAM) result in coarse grain structures or highly textured columnar grains. Different strategies can provide more random textures with lower defect content and finer, more homogenous grain size distribution. For instance, annealing will trigger the rearrangement of dislocations in a deformed material, and may promote nucleation of recrystallization. At high-angle grain boundaries, dislocation-free crystallites will form and grow to replace the initial microstructure. In this regard, a precise microstructural control becomes essential for ensuring good quality of a metallic part. Yet, the capacity to successfully refine the microstructure is highly dependent on the specimen's initial state. For example, LAM 316L samples exhibit slower kinetics and a higher recrystallization temperature than conventionally produced 316L.

In this study, we propose to apply a short laser scan on a highly deformed 316L steel, inducing recrystallization over a prescribed area, and over a certain depth below the surface. The nature of the heat source leads to very high heating and cooling rates, giving access to fast microstructure evolution kinetics, and over a volume encompassing a statistically significant number of grains. For a precise control of local temperatures without melting the material, the laser is defocused such as to increase the effective spot size, and laser scanning is repeated multiple times to establish a quasi-steady state in the induced temperature field. The latter is numerically simulated using finite element modelling. The progress of recrystallization is tracked using high- frequency acquisition of synchrotron XRD patterns, and different steps of microstructure changes are identified thanks to EBSD and TEM characterization. It is demonstrated that local laser annealing is an effective tool for in-situ monitoring and tailoring of recrystallization and grain structure in a highly deformed 316L steel.

This study also paves the way for local tailoring of microstructures using laser treatments. One important application relates to the field of additive manufacturing of metals and alloys, in which, most of the time, post heat treatments are needed for reaching the desired properties. The proposed laser treatments would not only reduce the need of such post treatments; their selectivity would also provide the ground for fabricating composite-like or architected microstructures.

The in situ synchrotron XRD experiments were performed at the Materials Science beam line of the Swiss Light Source using a miniaturized L-PBF device.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537, e-mail: steven.vanpetegem@psi.ch

Original Publication

Monitoring of laser-induced fast recrystallization in SS-316L through synchrotron X-ray diffraction

Claire Navarre, Steven Van Petegem, Lucas Schlenger, Cyril Cayron, Milad Hamidi-Nasab, Reza Esmaeilzadeh, Charlotte de Formanoir, Nicola Casati, Roland E. Logé

Materials and Design 238 (2024) 112628

DOI: 10.1016/j.matdes.2023.112628