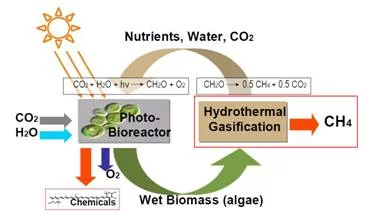

Over the last 10 years there has been increasing interest in using microalgae as a biofuel source. Microalgae are a promising bio-resource since they do not compete with food crops and show higher photosynthetic efficiency and biomass production rates compared to terrestrial plants. The hydrothermal gasification appears to be a promising technology to convert microalgae to biomethane within a few minutes. The SunCHem project aims at demonstrating the technical and economic feasibility of biomethane production from microalgae (Fig. 1). The novelty of this process is the recycling into the photo-bioreactor of all the liquid (rich in nutrients) and gaseous effluents (CO2) after the hydrothermal gasification

Fact Sheet HTV.pdf

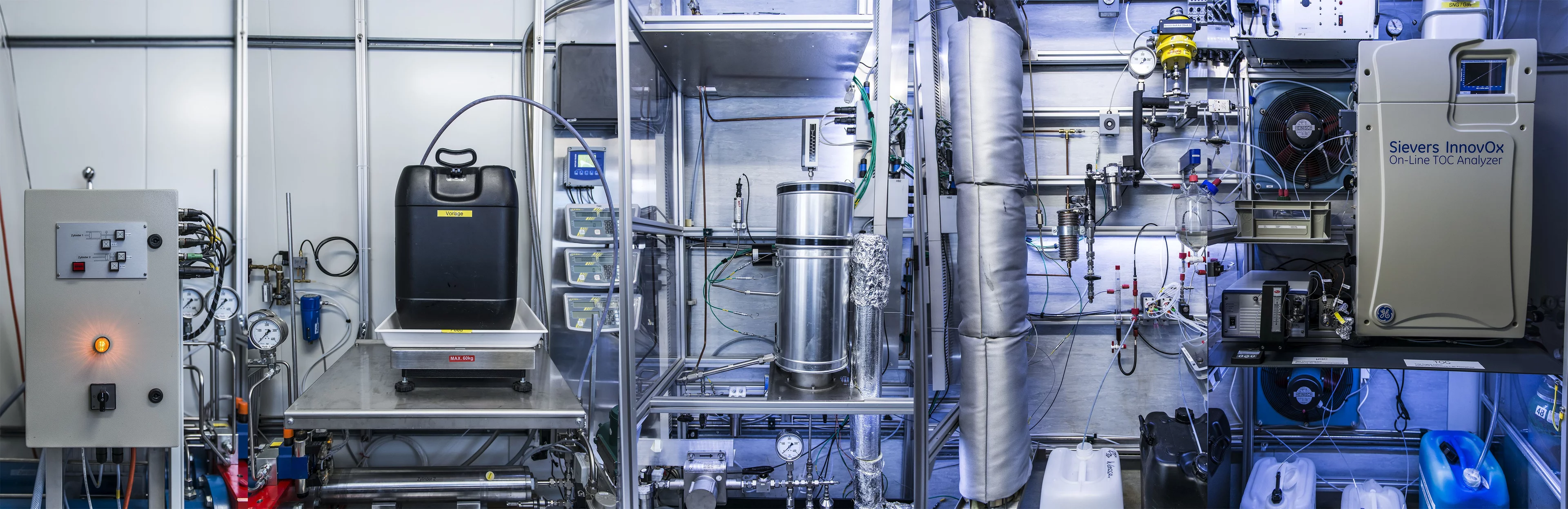

As shown in Fig. 2, a pilot demonstration unit has been built within a 20’ ship container (KONTI-C) in order to perform some demonstrations directly on microalgae production sites.

Features of KONTI-C:

- Microalgae pumped as a slurry (10 - 20 wt. % of DM) at 1 kg/hours

- Pressure max = 40 MPa

- Temperature max = 550 °C

- New salt separator design (patent filed)

- Gaseous effluents analysed online by a MicroGC

- Liquid effluents analysed online by TOC and conductivity

- Highly automated (liquid sampling, temperature profile measurements) and remote controlled.

The SunChem project is led by Prof. Dr. Christian Ludwig and is financially supported by CCEM-CH and Swisselectric research.

More about the SunCHem Project under following links: