LNM has a leading position in front-edge cut material characterizations of highly radioactive and contaminated fuel/cladding, structural and target materials from nuclear power plants and research facilities by sophisticated beam-line techniques at SLS/SINQ and by electron microscopy in EMF.

The new fully shielded FIB/SEM in our hotlab allows the targeted and efficient micro-sample preparation of highly radioactive materials and an activity reduction below the acceptance limits of the different facilities. In combination with the availability of highly relevant irradiated materials from the Swiss nuclear power plants and STIP/SINQ or MEGAPIE this gives us opportunities that are worldwide unique.

Examples of current activities:

Examples of current activities:

- Evaluation of the microstructure and microchemistry evolution in spent fuel, e.g., in high burn-up or doped fuel (Figure 1).

- Speciation and identification of crud deposits on fuel elements.

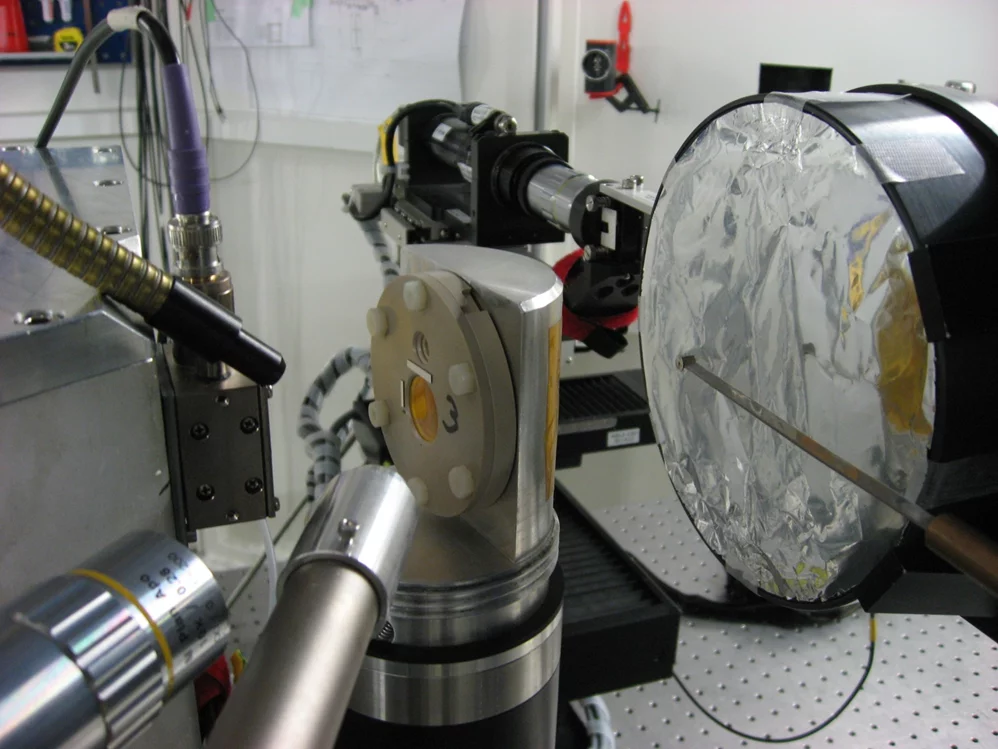

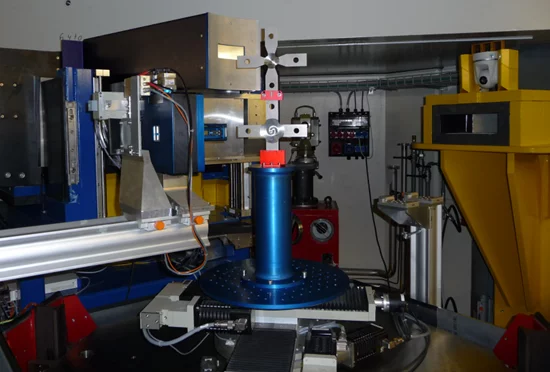

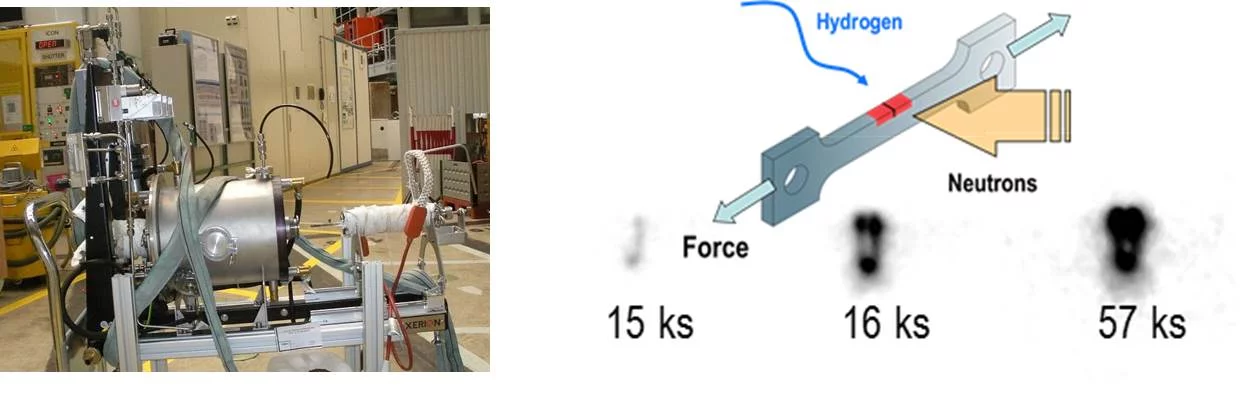

- In-situ mechanical testing or in-situ precipitation characterization for material degradation model development and validation, e.g., for fatigue (Figure 2) and fracture in steels or hydride formation in fuel claddings (Figure 3).