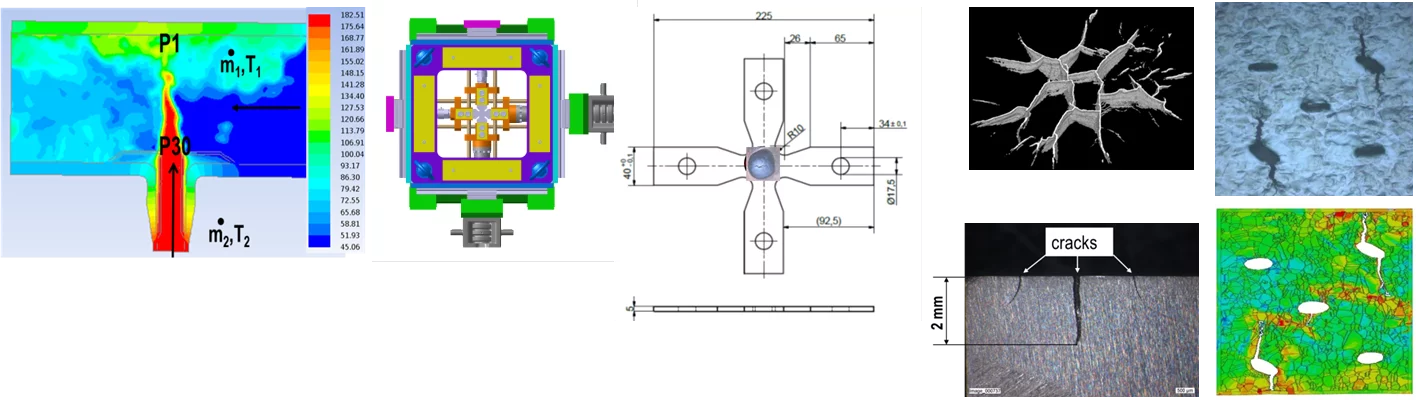

The current PLiM project (2014-2017) is funded by swissnuclear and is dealing with the development of improved advanced lifetime prediction models for thermo-mechanical fatigue (TMF) in austenitic stainless steel piping under complex thermo-hydraulic boundary conditions, and with their validation by specially designed fatigue tests under plant-relevant conditions.

Specific thermo-hydraulic conditions, e.g. turbulent mixing of hot and cold water, may lead to cyclic thermal shocks (CTS) in the primary circuit piping of light water reactors. This may result in crack initiation, possibly followed by crack growth and failure of the component. In spite of the large body of scientific investigations worldwide in this area, the exact conditions which lead to thermal fatigue and associated development of crack networks, caused by turbulent mixing, are not yet fully understood, and more research is needed in both thermal-hydraulics and structural mechanics. The main questions are:

- Under which flow conditions do the thermal fluctuations appear?

- What are critical locations for crack formation in the primary loop of light-water reactors?

- What are the temperature differences ΔT and frequencies of these fluctuations?

- Which conditions (ω, ΔT, mean temperature Tm, pressure) have to be fulfilled for the initiation and growth of thermally induced cracks?

- How deep do these cracks grow? Under what conditions do they arrest?

- What are the reliable materials models for thermal fatigue life prediction?