The project Nuclear Fuels focuses on aspects of nuclear reactor core internals. The most important is the fuel itself, i.e. the fuel rods consisting of ceramic fuel pellets and the surrounding cladding, made of a zirconium alloy. The interest is on the physical, chemical and mechanical properties of these components and their respective influence on the performance and safety during operation in the nuclear power plant, but also after service during handling or storage periods.

The Nuclear Fuels team uses the typical investigation tools for radioactive materials, in close cooperation with the colleagues from the PSI hotlab, the Electron Microscopy Facilities (EMF) and the PSI large scale facilities like the synchrotron (SLS) and the neutron source (SINQ).

A close collaboration with Fuel Modelling scientists complements the research work for better understanding specific questions of fuel behavior.

The Nuclear Fuels project contributes with its expertise to international programs, supports the Swiss nuclear power plants and regulators in respective materials questions and trains future specialists (PhD projects etc.).

The project focus is on three main aspects and one emerging direction:

-

H-Uptake into cladding: During service in the power plant, at the hot surface of the fuel rod, water is broken up into oxygen and hydrogen: the first leading to oxidation, the latter is partially taken up into the cladding and provokes embrittlement. The mechanism of the hydrogen uptake into the cladding, through the oxide layer, is not yet understood. The microstructure at the metal-oxide interface, the alloy composition and cladding manufacturing route are part of the complex interplay of factors ruling this phenomenon.

-

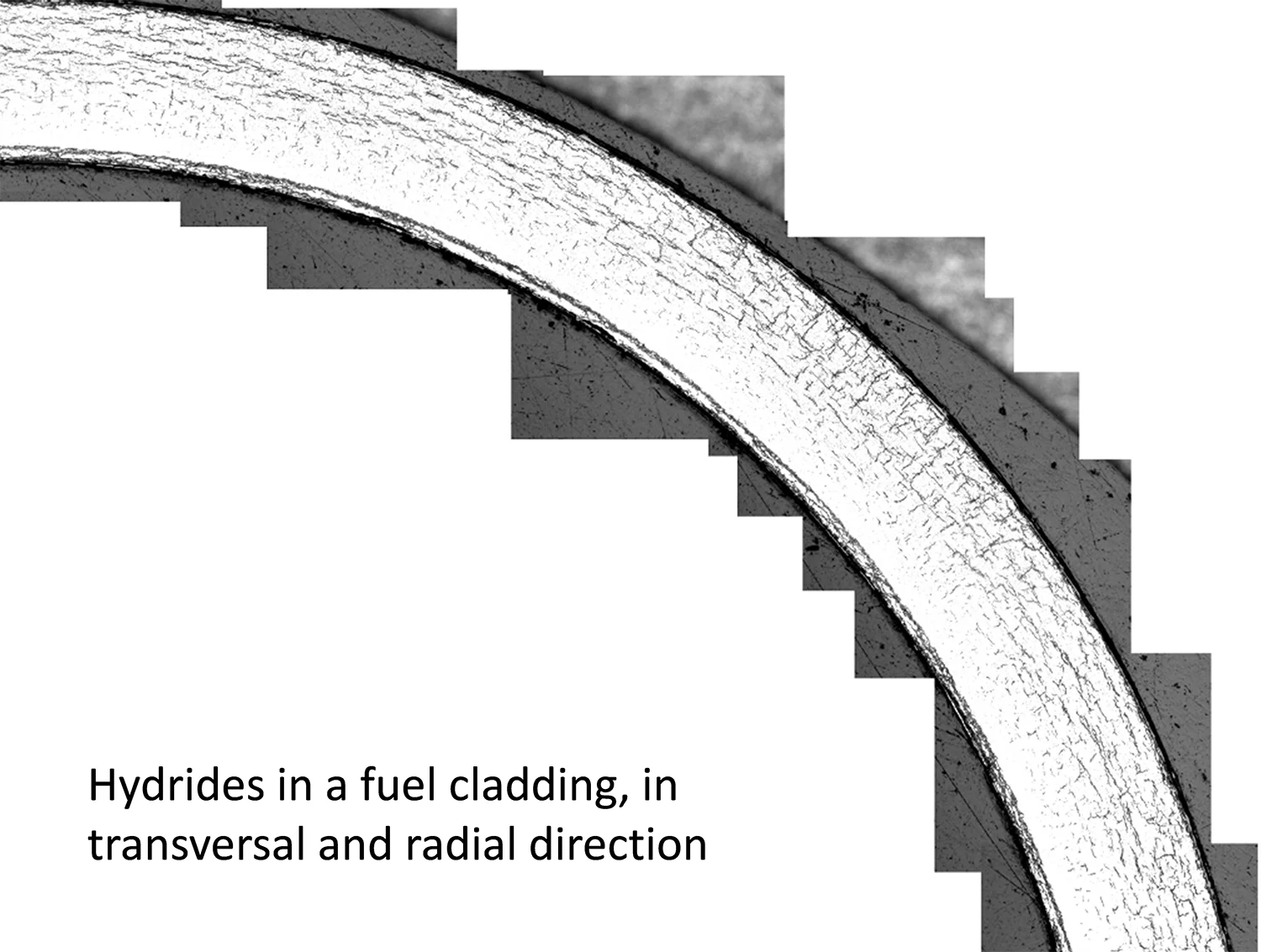

Influence of hydrogen on cladding: The increasing concentration of hydrogen in the cladding with increasing burn-up has an impact on the cladding mechanical properties. The interest of this part of the project is focused on the diffusion and precipitation of hydrogen and the quantification of impact on the mechanical properties and failure mechanisms. The image analysis software HYDIVA, developed at PSI, allows on a fuel rod cross section a full 360° hydrides determination with respect to each hydride’s location, length and orientation.

-

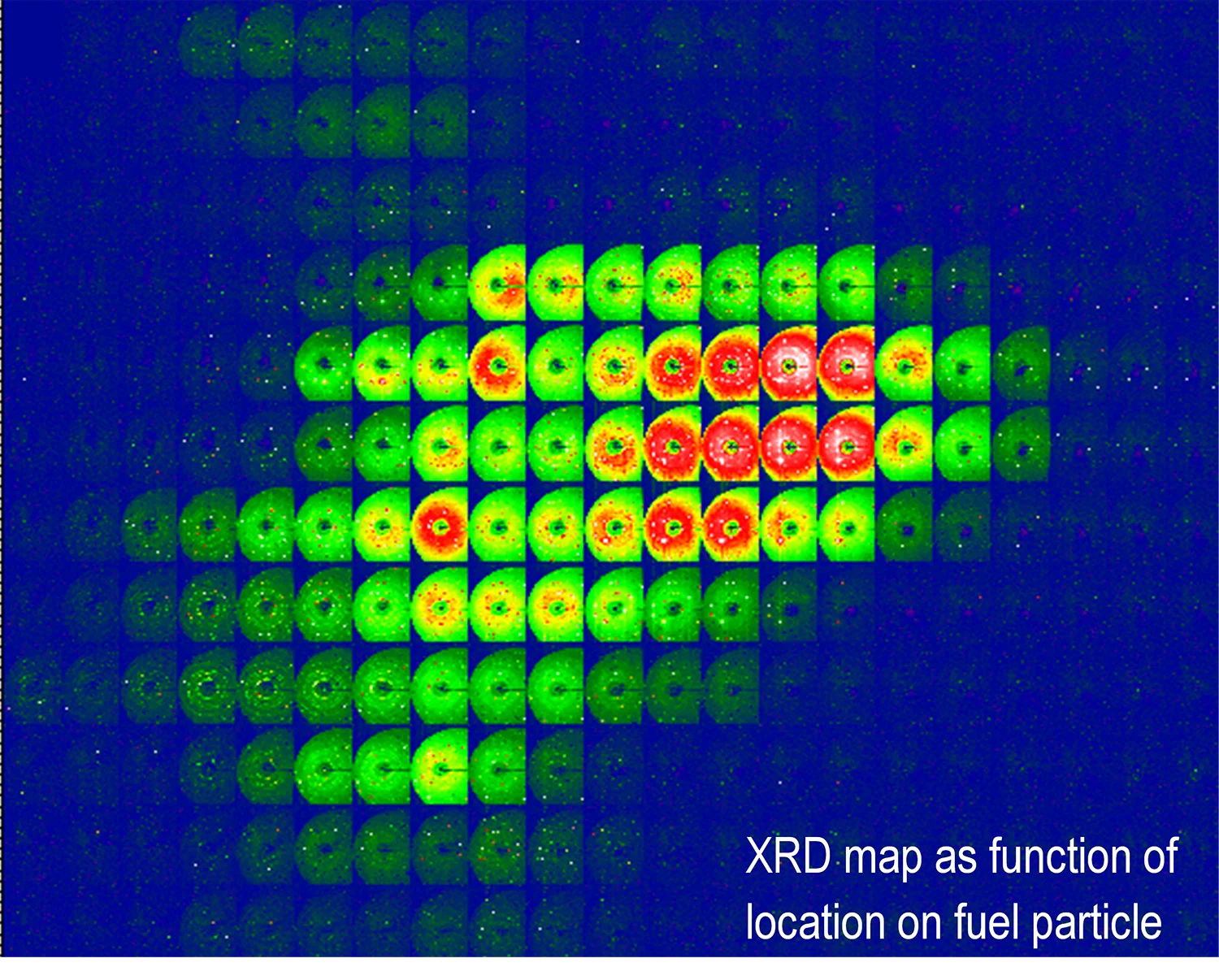

Fuel properties changes during burn-up: The fuel pellet material changes its structure and chemistry with increasing burn-up, with impact on the thermal conductivity, mechanical stability, its fission gas distribution or on the interaction with the cladding. This part of the project focuses on related questions, always taking the safety and performance of the fuel into account.

-

Accident Tolerant Fuel (ATF): ATF for light water reactors is an emerging topic for the Nuclear Fuels project, currently monitoring the various international trends.