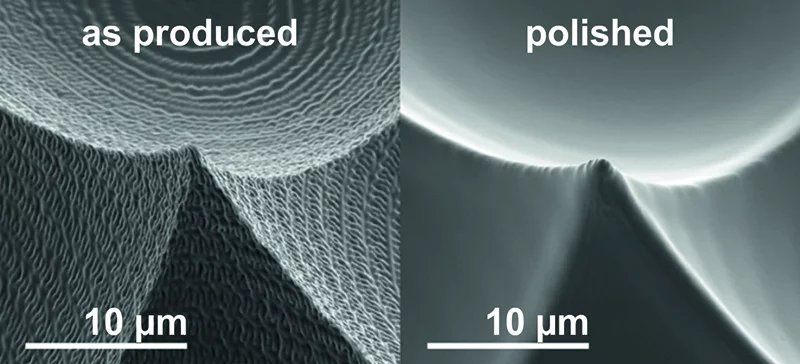

Researchers at the Paul Scherrer Institute together with the company Heptagon have developed a method to produce micro-optics with ultra-smooth surfaces. This contact-less polishing method is especially important for new 3D lithography methods, which can provide innovative optical functions but suffer from surface roughness and imperfections. When applying the newly developed method, the fabrication time of such micro-optics can be significantly reduced.

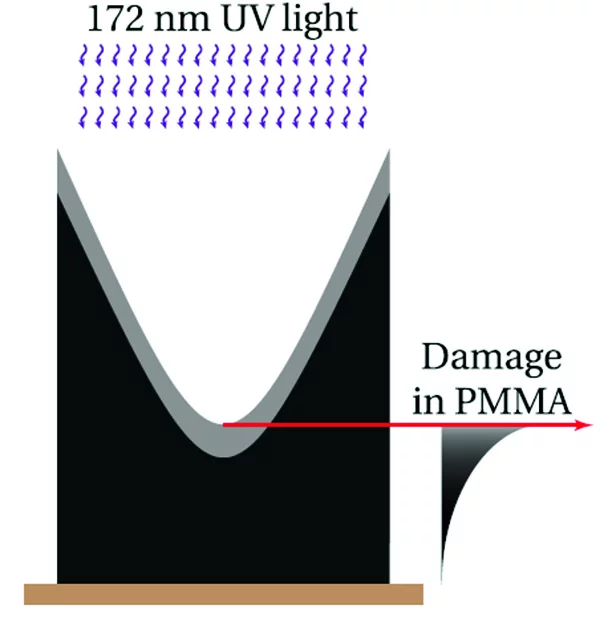

The key to the success of the new method is the reduction of the glass transition temperature of linear thermoplastic polymers like PMMA which is often used in the production process of micro-optics. This reduction is confined to a surface layer of less than 500 nm by using high-energy photons such as from 172 nm UV light. After heating of the micro-lenses above the glass transition temperature of this very thin layer, the self-arrangement and energy minimization of this thin layer led to the removal of surface roughness in the same size range than the thickness of the modified layer, finally yielding ultra-smooth surfaces.

N. Chidambaram, R. Kirchner, R. Fallica, L. Yu, M. Altana and H. Schift

Selective surface smoothening of polymer microlenses by depth confined softening

Adv. Mater. Technol. 1700018 (2017) 1-10.