XAS and XES characterization of catalytic and other materials at the SuperXAS beamline at the Swiss Light Source can be performed under conditions mimicking operational. The capillary setup allows studying materials under controlled temperature, pressure and gas environment. XAS and XES measurements can be done simultaneously with monitoring of the catalytic activity using on-line mass spectrometry, gas chromatographry or IR analysis of the gas phase. The capillary setup can be also used for in situ and operando XRD and PDF experiments at other facilities.

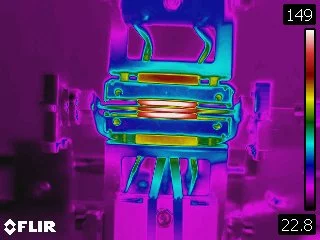

Our capillary reactor can be heated using with three types of heating devices: infrared heaters, resistive heaters [P. J. Chupas et al, J. Appl. Cryst. (2008). 41] or air-blower allowing to control the temperature up to 900 oC. Figure 1 shows the infrared image of the reactor: the middle part shows two infrared heaters and 1 mm quartz capillary. Temperature of the sample inside the reactor can be either calibrated prior to the experiment or monitored during the experiment using an additional thermocouple. We commonly use quartz, kapton or borosilicate glass capillaries. The setup allows working with capillaries of 1, 2 and 3 mm outer diameter. The sieved powder sample (100-150 um or similar) is typically placed in the capillary reactor within 5-10 mm and fixed between two quartz wool plugs. Use of sieved powder is particularly important for flowing gas through the sample. Epoxy and other glues can employed to seal the capillary to the stainless steel frame [W. van Beek et al, Phase Transitions. (2011). 84] to avoid gas leaks.

Due to the plug flow nature of the capillary setup and its low dead-volume, it is particularly suitable for kinetics studies, fast gas switching experiments and modulation-excitation spectroscopy.

Figure 1. Infrared image of the capillary setup at work.