Concrete is a fluid mass that strikingly sets and hardens in hours, even under water. This fabricated rock, which is made of cement, water, sand and gravel, is the basic building block of our civilization. Hence, it is not a surprise that it is the world’s largest fabricated commodity. The enormous production of Portland cement (PC), at 4 billion tonnes per year, results in 2.7 billion tonnes per year of CO2 emissions. If cement production were considered a country, it would be the third CO2 emitter in the world, just after China and USA. Therefore, reducing the CO2 footprint of cement, mortar and concrete is a societal need.

The main drawback of the current proposals for low-carbon cements is the slow hydration kinetics in the first 3 days. “Understanding the processes related to cement production as it takes place at its early stages is crucial”, explains Shiva Shirani, first author of the paper and PhD student at the University of Málaga. Despite a century of research, our understanding of cement dissolution and precipitation processes at early ages is very limited. “So we have developed a methodology to get a full picture of the hydration of Portland cement”, she adds.

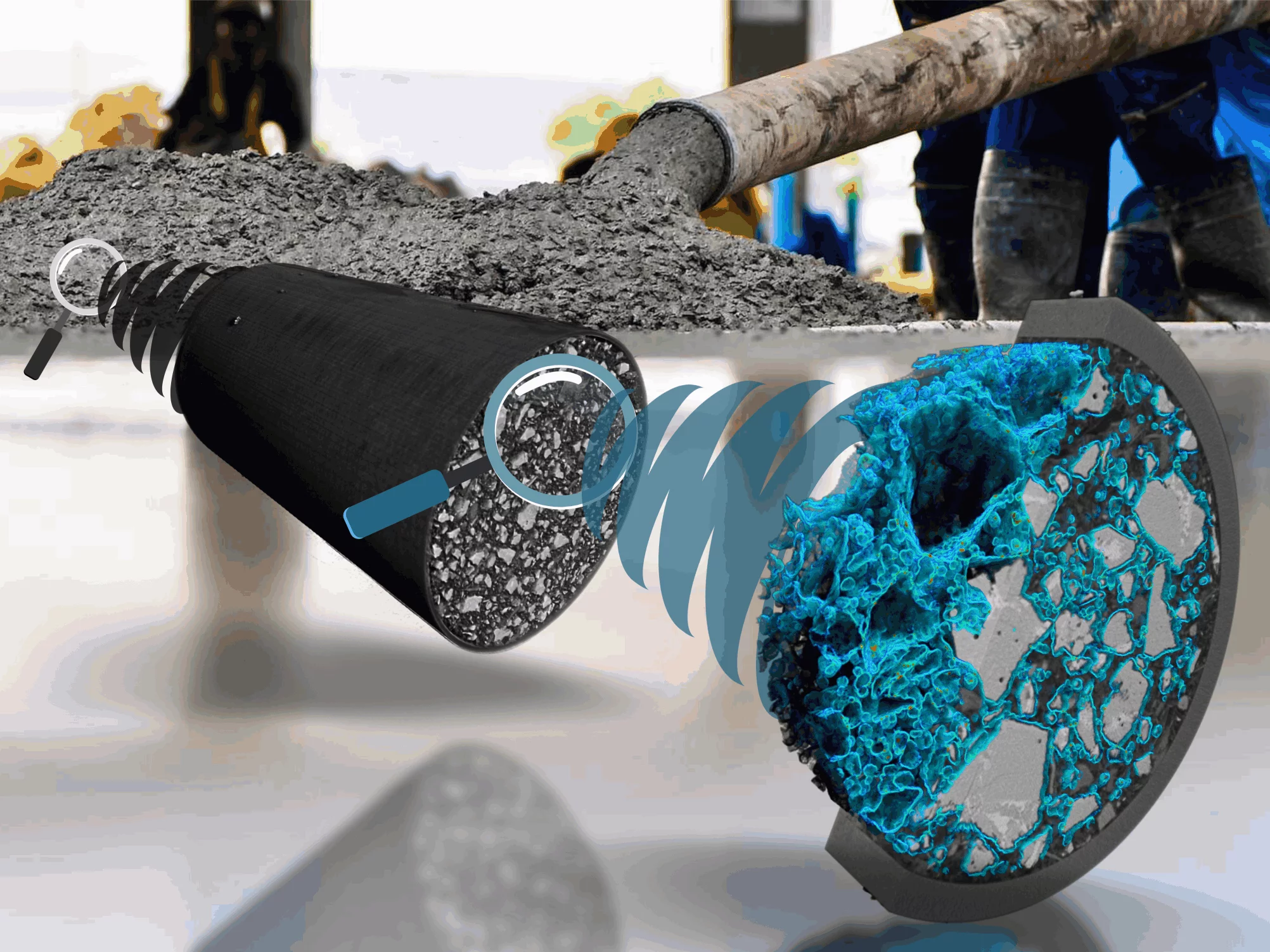

The team, which is led by the University of Málaga and includes the ESRF, the Paul Scherrer Institute PSI (Switzerland) and the University Grenoble Alpes (France), carried out a tomographic study in the laboratory for an initial characterisation, followed by phase-contrast microtomography experiments with synchrotron radiation to take data very quickly and in large sample volumes, and finally experiments at the nanometric scale, using synchrotron ptychotomography.

The scientists combined complementary experimental approaches at the ESRF and the Swiss Light Source (SLS) at the Paul Scherrer Institute to get spatial and temporal data (4D). The experiments at ID19 beamline of ESRF allowed the team to follow a large volume of a hydrating PC paste with a temporal resolution of 5 minutes, yielding very accurate hydration degrees as a function of the particle sizes and time. 4D data were also taken at the cSAXS beamline of the Swiss Light Source, with higher spatial resolution and contrast, but in a volume 640 times smaller and needing 180 minutes per dataset.

Near-field ptychotomography unveiled the hydration of commercial PC. The spatial dissolution rate of small alite grains, the main component of PCs, during the first day, is 100 nm/h, being four times faster than that of large alite grains in the following three days, 25 nm/h. Moreover, at 19 h, a porous calcium silicate hydrate gel shell with a thickness of 500 nm covers every alite grain enclosing a water gap.

Miguel A.G. Aranda, professor at the Universidad de Málaga and corresponding author of the publication, highlights "This study is the first step in a detailed visualization of cement hydration at these ages. Understanding the mechanics of the slowest processes will hopefully lead to strategies to rationally accelerate the hydration of low-carbon cements, such as faster strength-enhancing admixtures, which are needed to timely remove the formwork".

Contact

Dr. Ana Diaz

Senior scientist, Swiss Light Source

Paul Scherrer Institut

Telephone: +41 56 310 56 26

E-mail: ana.diaz@psi.ch

Original Publication

4D nanoimaging of early age cement hydration

Shiva Shirani, Ana Cuesta, Alejandro Morales-Cantero, Isabel Santacruz, Ana Diaz, Pavel Trtik, Mirko Holler, Alexander Rack, Bratislav Lukic, Emmanuel Brun, Inés R. Salcedo, and Miguel A. G. Aranda

Nature Communications 14, 2652 (2023). doi: 10.1038/s41467-023-38380-1

Other links