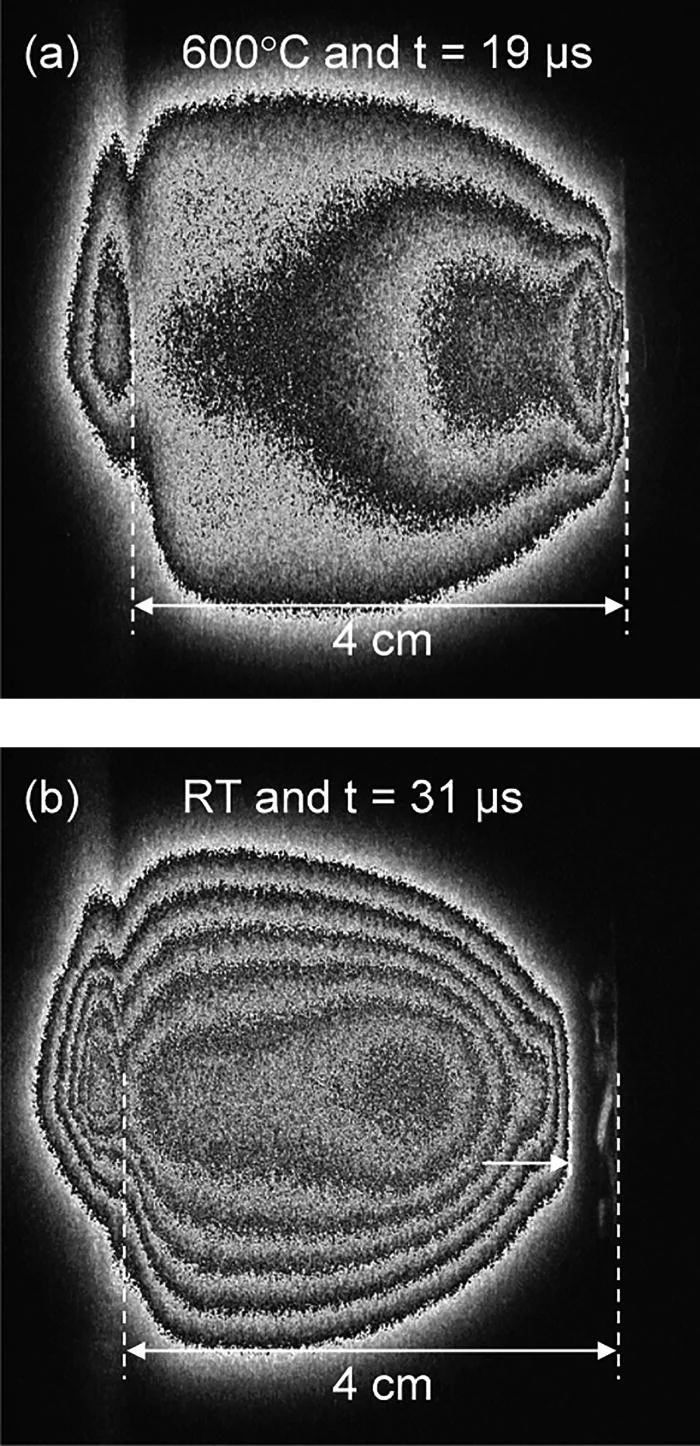

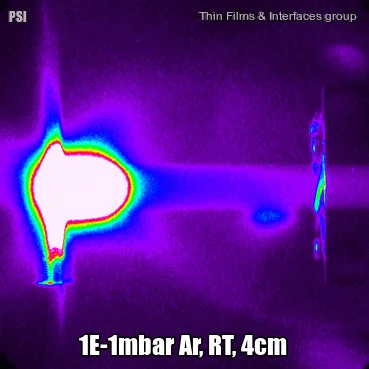

The influence of different background gases and substrate heating on the plasma plume dynamics from silver ablation is investigated by species selected time and space resolved imaging. The results provide a time-resolved understanding on how those process parameters affect the expansion: from a free expansion in vacuum with velocities exceeding 20'000 m/s to a very slow expansion in Ar at 1 × 10−1 mbar with arrival velocities of 280 m/s. In addition, we observe a rebound of the ablated material on the substrate holder leading to a re-coating of the ablated target. At 1 × 10−1 mbar, it seems that the expansion of the plasma plume displaces a considerable portion of the background gas and traps it against the frontal area of the substrate holder. This leads to a transient high local pressure just above the substrate. In the case of Ar, the rebound is enhanced due to inelastic scattering, whereas for an O2 background, an area of high reactivity/emission in addition to the rebound is created. Imaging of selected species shows that the light emission in this area is mainly due to excited Ag and metal oxygen species. There is a clear influence of substrate heating on the plasma expansion due to the background gas density gradients, reducing the stopping ability of the background gas and already detectable 2 cm away from the substrate. Both rebound and excitation effects are reduced in intensity due to the substrate heating.

Facility: ENE, LMX, Thin Films and Interfaces

Reference: A. Ojeda et al, J. Appl. Phys. 120, 225301 (2016)

Read full article: here