The LIN Mechanical and Electrical Engineering group has long experience in developing, maintaining and operating of advanced electronics equipment at large instrumentation. Particular skills in the electronics group are:

- electrical and electronics engineering

- cabling and installation of entire instruments

- maintenance and operation positioning systems

- maintenance and operation of motor control systems

- maintenance and operation of data acquisition systems

- maintenance and operation of neutron monitors

- maintenance and operation of neutron detectors

- control + automation systems (SPS units)

- control and alarm units

- development of a 2nd generation electronics equipment in collaboration with the Electronics Group of LTP within NUM (Motor control units, magnet controller, data acquisition)

Below there is a short summary of these skills.

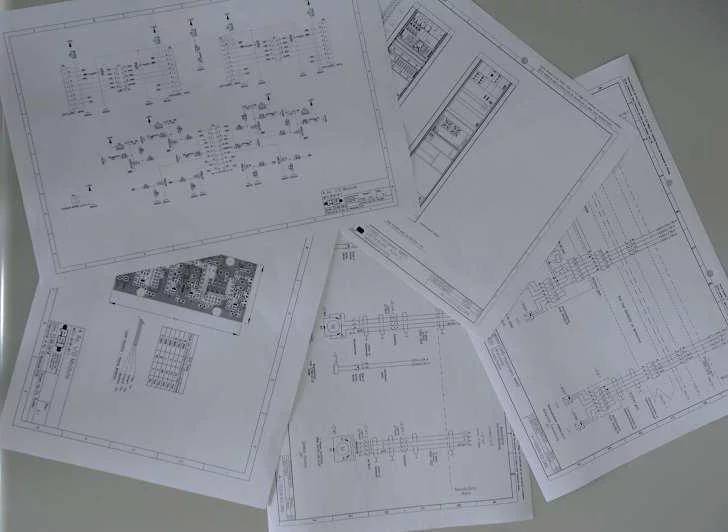

Electrical and electronics engineering (CAD, Software, Hardware)

Cabling and installation of entire Instruments

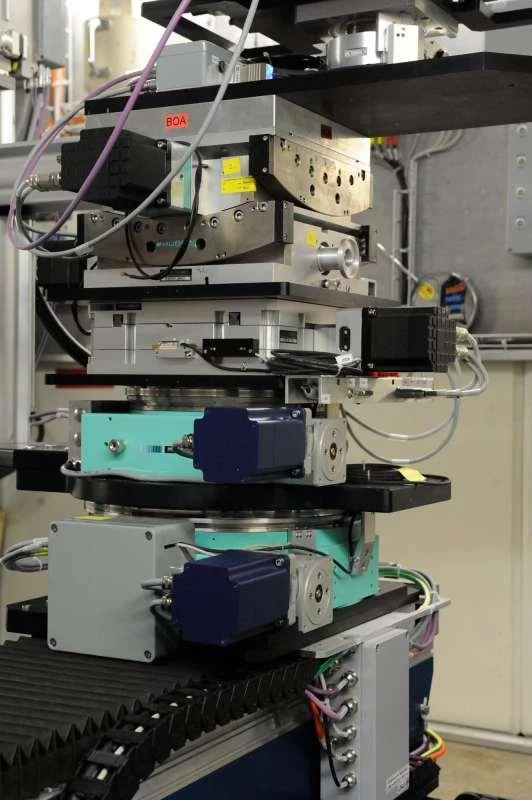

Maintenance and operation positioning systems

Maintenance and operation of motor control systems

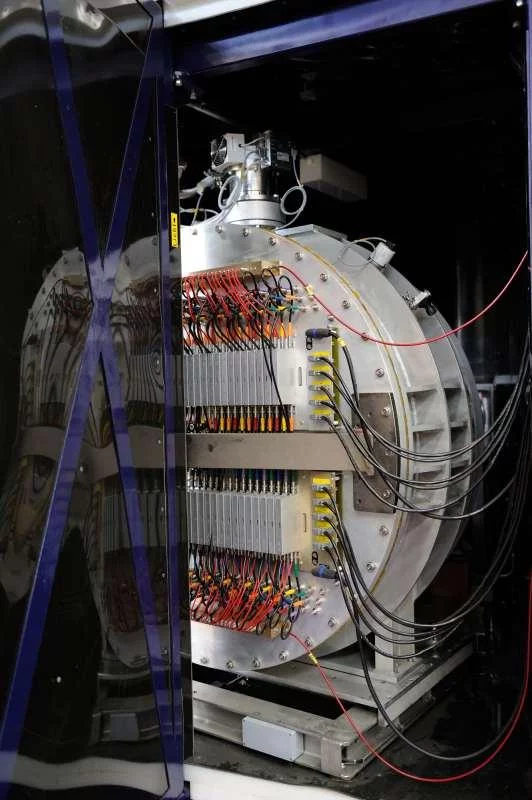

Motor control unit, in collaboration with our electronic group LTP we develop, install and operate the new 2nd generation multiturn axis control system. The modular concept is able to steer up to 32 axis with 2-phase, 3-phase and 5-phase, linear stepper motors, increment or absolute encoders, limit and homing switches, air cushion control and many other applications.

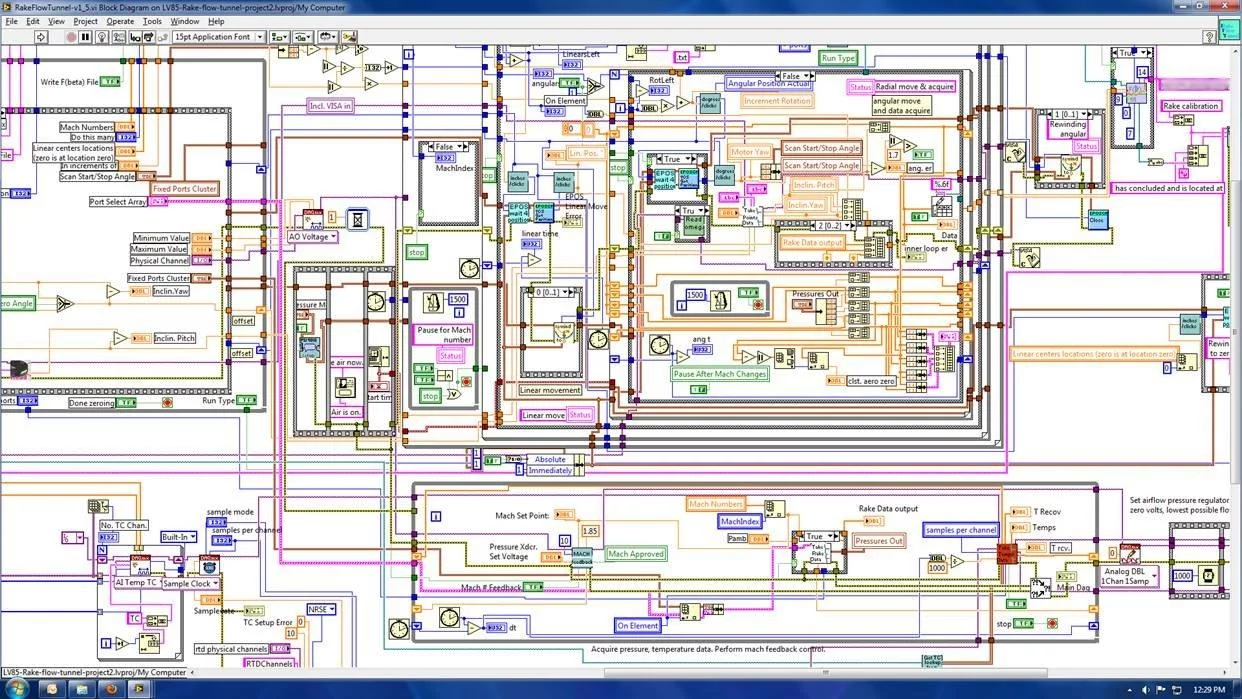

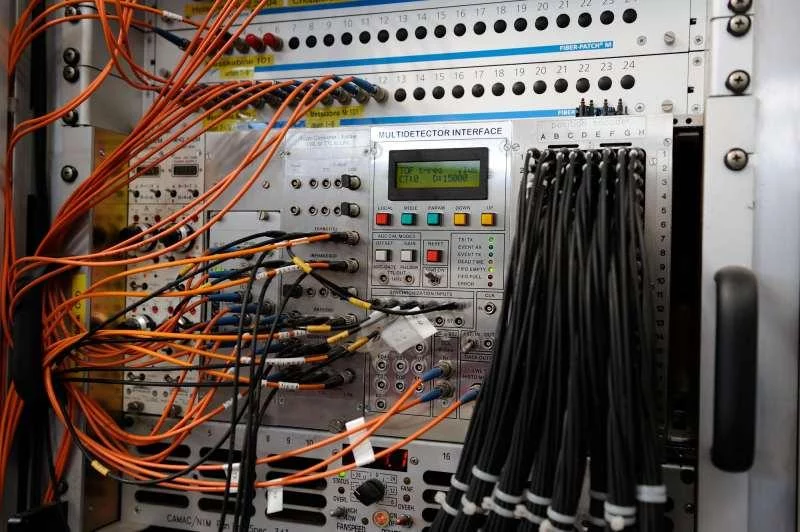

Maintenance and operation of data acquisition systems

Together with the electronic group LTP we develop, support and operate all SINQ electronic instrumentation around neutron detectors and neutron monitors.

Maintenance and operation of neutron monitors

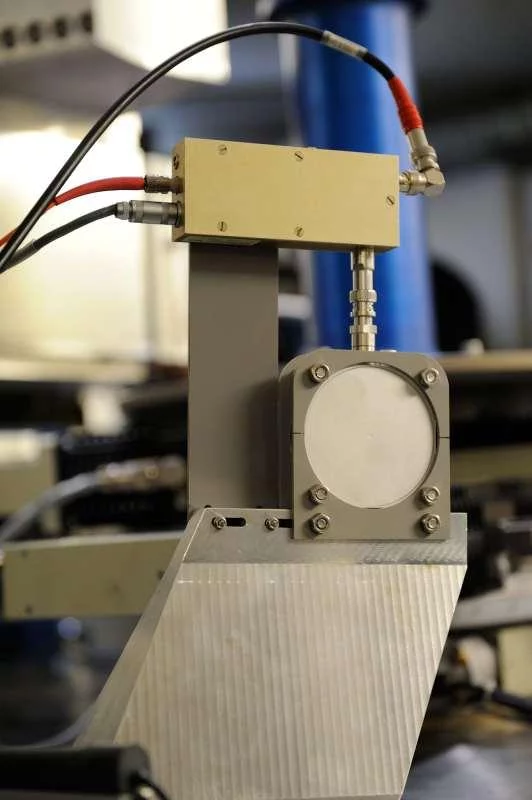

Neutron monitors are small and have an unimpressive look. But technology is difficult. Inside of the monitor there is U235 vacuum metallised. Under high voltage the monitor is able to detect neutrons. At SINQ the monitors are used to measure the constant neutron flux to the sampling. It is the reference of neutron flux for all experiments.

Maintenance and operation of neutron detectors

Our group supports all the electronic stuff around detectors. We test and repair 1D-, 2D- and 3D-Detectors at SINQ.

Control and automation systems

All the electronic sensors and actors need to be controlled by the user at SINQ instruments. Our electronics group is able to implement and set up SPS control units in hardware and software.

Control and alarm units

In Conclusion

By the way our group is able to develop every new electronic component you wish to set up.