During fission of the fuel the UO2 pellets change their structural, mechanical, chemical and physical properties. Pushing the fuel to high burn-up is of interest to reduce the amount of highly radioactive spent fuel or waste per produced kWh. The research work concentrates on the changes of the fuel on the basis of this high burn-up, considering its still safe operation. The research work comprises the following aspects: fission products formation and distribution, induced stresses in the fuel and formation of sub-grains, formation of the so-called high burn-up structure, fuel additives or dopants and interaction between fuel pellet and cladding.

Various analytical methods are applied:

Various analytical methods are applied:

- Photon based – Synchrotron radiation techniques (μXRD, μXRF, μEXAFS, μXANES), γ-scanning, EDX

- Electron based – Scanning and Transmission Electron Microscopy (E)SEM and TEM, Electron Energy Loss Spectroscopy EELS, Focused Ion Beam FIB, Electron Probe Micro Analyzer EPMA

- Isotopic analyses – Mass spectrometry (SIMS, LA-ICP-MS)

- Others – Light optical microscopy, fission gas measurements, Positron Annihilation Spectroscopy (PAS)

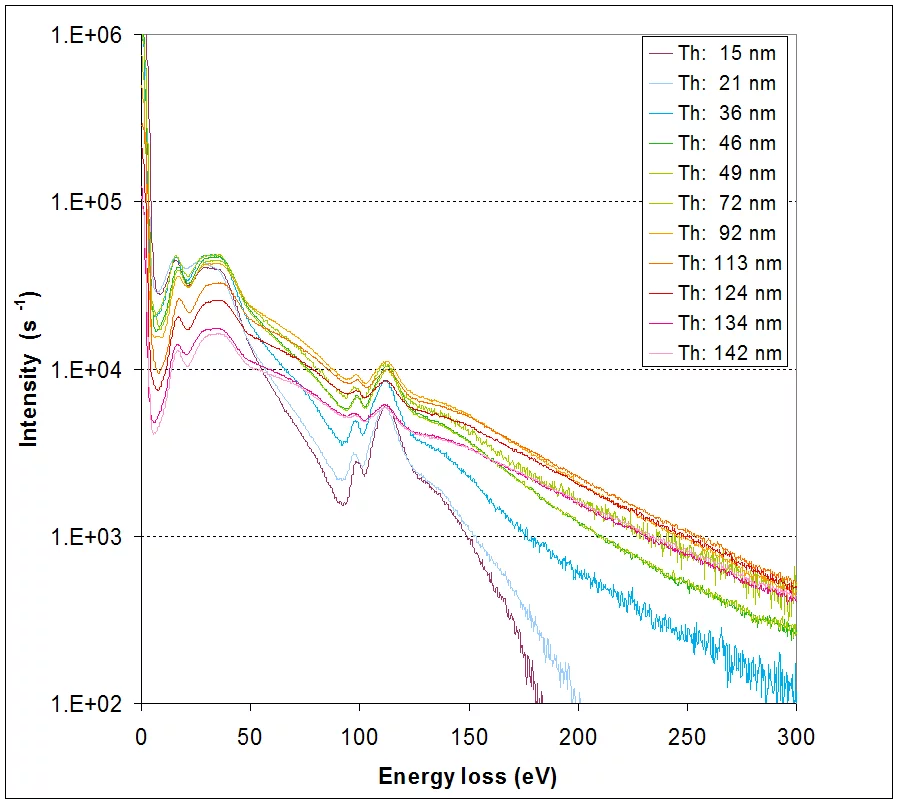

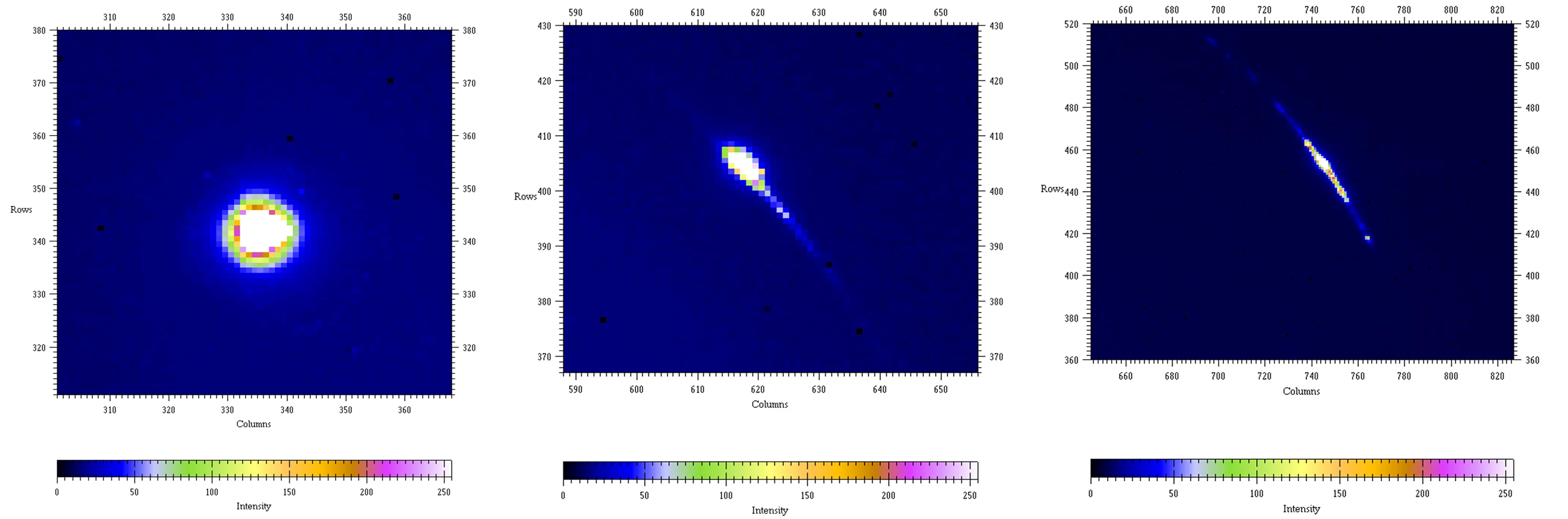

Example – TEM for studying the electron energy loss

Lamellae of UO2 are used to quantitatively analyze the EEL spectra as function of sample thickness. The M, N, O and P edges are recorded from 0 to 4000 eV loss, allowing recon-struction of the electronic transitions. The edge analysis also helps to identify the plasmon peak of the core electron transition. Going through a range of thicknesses (~20 to ~200 nm) the electron mean free path and cross section for inelastic scattering can be derived in the plasmon part of the spectrum.

Example – XAS and fission products

X-ray absorption spectroscopy (XAS) can be used to determine the atomic environment of specific elements, e.g. of fission products. The analysis of volatile krypton in irradiated UO2 has been successfully achieved by XAS. Taking into account that the formation of fission gas bubbles is mainly governed by the production of xenon, and knowing the ratio between xenon and krypton, an estimation of atomic density in the gas bubbles is possible. Further: non-volatile fission products are mostly of interest in respect to their chemical bonds (e.g. metallic fission products).

Example – XRD and fuel structure

With increasing burn-up the fuel grains suffer more and more restructuring, starting with distortion, increasing dislocation densities, forming sub-grains with small-angle boundaries and ending up with fuel polygonization. The restructuring is of interest in case of temperature transients of the fuel which can lead to fuel fragmentation (or, in extreme cases, pulverization). The induced stresses which are presumably the driving force for restructuring can be analyzed with X-ray Diffraction XRD.