Laser-based Powder Bed Fusion (L-PBF) is a rapidly developing additive manufacturing method that has revolutionized the manufacturing sector. L-PBF offers the possibility to manufacture near-net-shape complex objects, but in the meantime, bears the promise of achieving complex microstructures or multimaterials, through local manipulation of the process parameters. Several processing parameters, including layer thickness, scanning strategy, hatch distance, spot size, laser focus, and power of the laser have to be optimized for L-PBF to achieve dense parts and the desired microstructures. The thermal history that each layer undergoes is greatly affected by the building parameters and hence the final microstructure and the mechanical properties are sensitive to the building parameters. Moreover, post-built heat treatments are able to relieve the residual stresses that build up [1] and to affect the material properties, already attained during the L-PBF process.

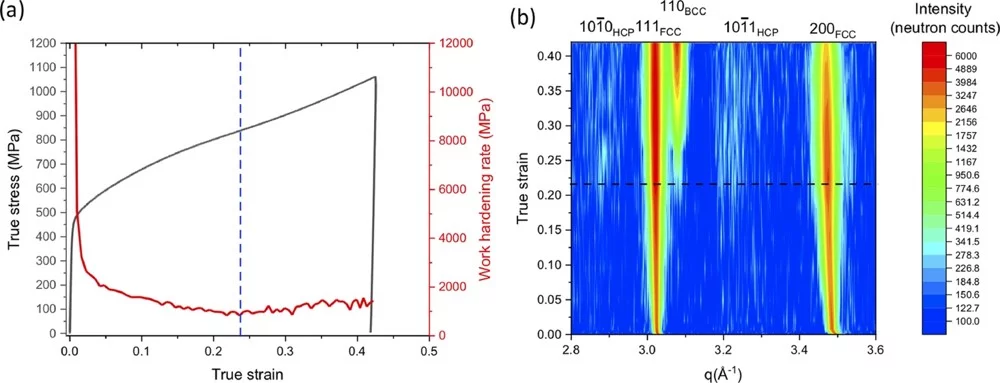

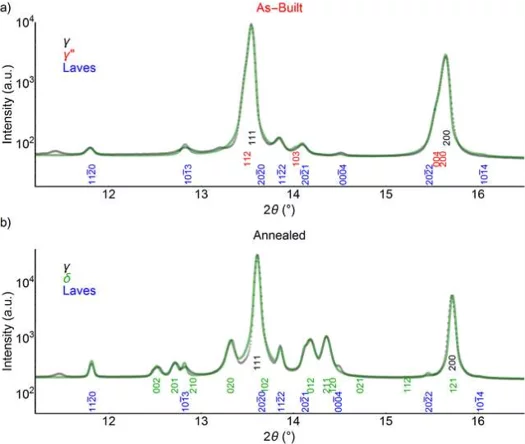

Within two ongoing projects we utilize L-PBF techniques for optimizing the mechanical behavior of two classes of technologically important alloy systems: austenitic stainless steels and nickel superalloys. By exploiting L-PBF, we manipulate the crystallographic texture of austenitic stainless steels, which leads to enhanced martensite formation/deformation twinning under deformation, and thus to enhanced strength and ductility [2]. We utilize neutron diffraction to follow the deformation behavior or these alloys, while in situ neutron/synchrotron X-ray diffraction during annealing are applied to follow the stress evolution and the precipitation in nickel superalloys produced by different AM process parameters [3].

The goal of these studies is to understand better the link between process parameters post-build treatments and materials properties and to be able to realize complex parts with tailored microstructures that best meet the mechanical requirements of the components under service conditions.

Publications

Collaboration

- Prof. R. Loge EPFL

- Dr C. Leinenbach, EMPA

Funding

- SNSF Projects No. 200021_188767

- ETH Domain SFA-AM

- Marie Skłodowska-Curie grant agreement No. 701647

Associated junior researchers

- C. Sofras, Dr. J. Capek

Contact

- Dr. E. Polatidis, efthymios.polatidis@psi.ch, +41 56 310 3948

- Dr. J. Capek, jan.capek@psi.ch, +41 56 310 5469