Laser Powder Bed Fusion (LPBF) is revolutionizing additive manufacturing by enabling the creation of intricate metallic components. Despite its potential, challenges remain in controlling the microstructure and ensuring consistent quality. This study introduces a novel approach to tackling these challenges through Acoustic Emission (AE) monitoring combined with Machine Learning (ML), providing real-time insights into the LPBF process, particularly for materials undergoing complex phase transformations.

The research focuses on the Ti-6Al-4V alloy (Ti64), a commonly used material in LPBF, enhanced with the addition of Fe as a β stabilizer. Incorporating 3 wt% and 6 wt% Fe into Ti64 led to significant changes in microstructural evolution, including reduced martensite formation and an increased volume of the β phase. These findings demonstrate the potential of in-situ alloying as a straightforward strategy to improve the material’s properties.

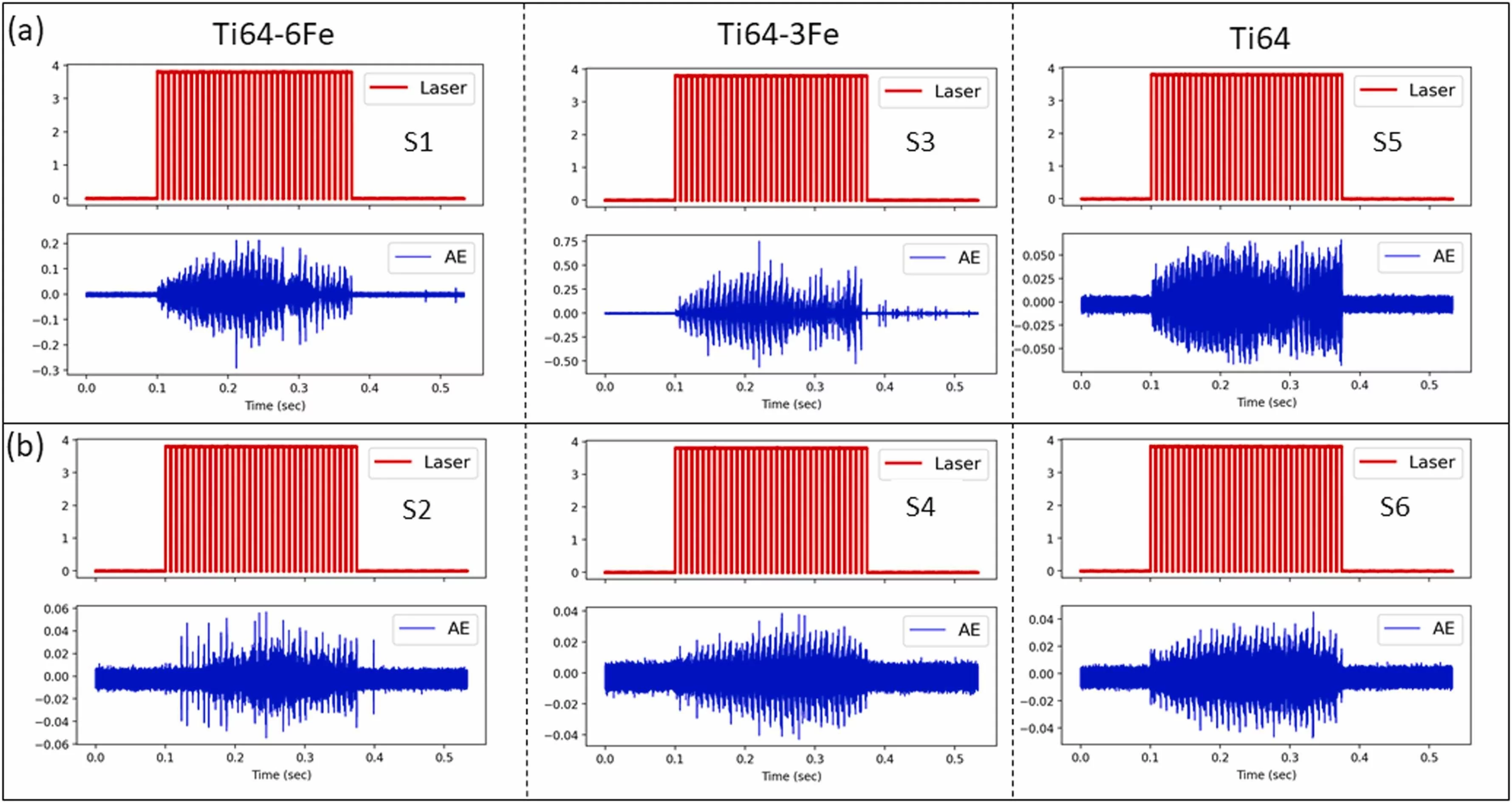

Acoustic Emission monitoring revealed acoustic signatures directly associated with phase transformations during the LPBF process. This represents the first detection of distinct AE footprints of martensitic transformations in LPBF, offering a powerful tool for real-time optimization of process parameters. Advanced ML algorithms classified AE signals with high accuracy, uncovering detailed insights into process stability and material behavior under varying conditions.

The integration of AE monitoring with operando synchrotron X-ray diffraction and advanced microscopy techniques provided a deeper understanding of how processing parameters influence microstructure and phase transformations. These complementary methods allowed for precise correlations between AE signals and the resulting material properties.

This study highlights the potential of AE monitoring as a versatile and cost-effective method for real-time quality control in LPBF. Coupled with in-situ alloying, this approach offers an efficient way to tailor microstructures and enhance mechanical properties without extensive post-processing. The findings mark a significant step forward in advancing additive manufacturing technologies, paving the way for the design and production of high-performance materials.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537, e-mail: steven.vanpetegem@psi.ch

Original Publication

Acoustic emission signature of martensitic transformation in Laser Powder Bed Fusion of Ti6Al4V-Fe, supported by operando X-ray diffraction

Reza Esmaeilzadeh, Vigneashwara Pandiyan, Steven Van Petegem, Mathijs Van der Meer, Milad Hamidi Nasab, Charlotte de Formanoir, Jamasp Jhabvala, Claire Navarre, Lucas Schlenger, Roland Richter, Nicola Casati, Kilian Wasmer, Roland E. Logé

Additive Manufacturing 96 (2024) 104562

DOI:10.1016/j.addma.2024.104562