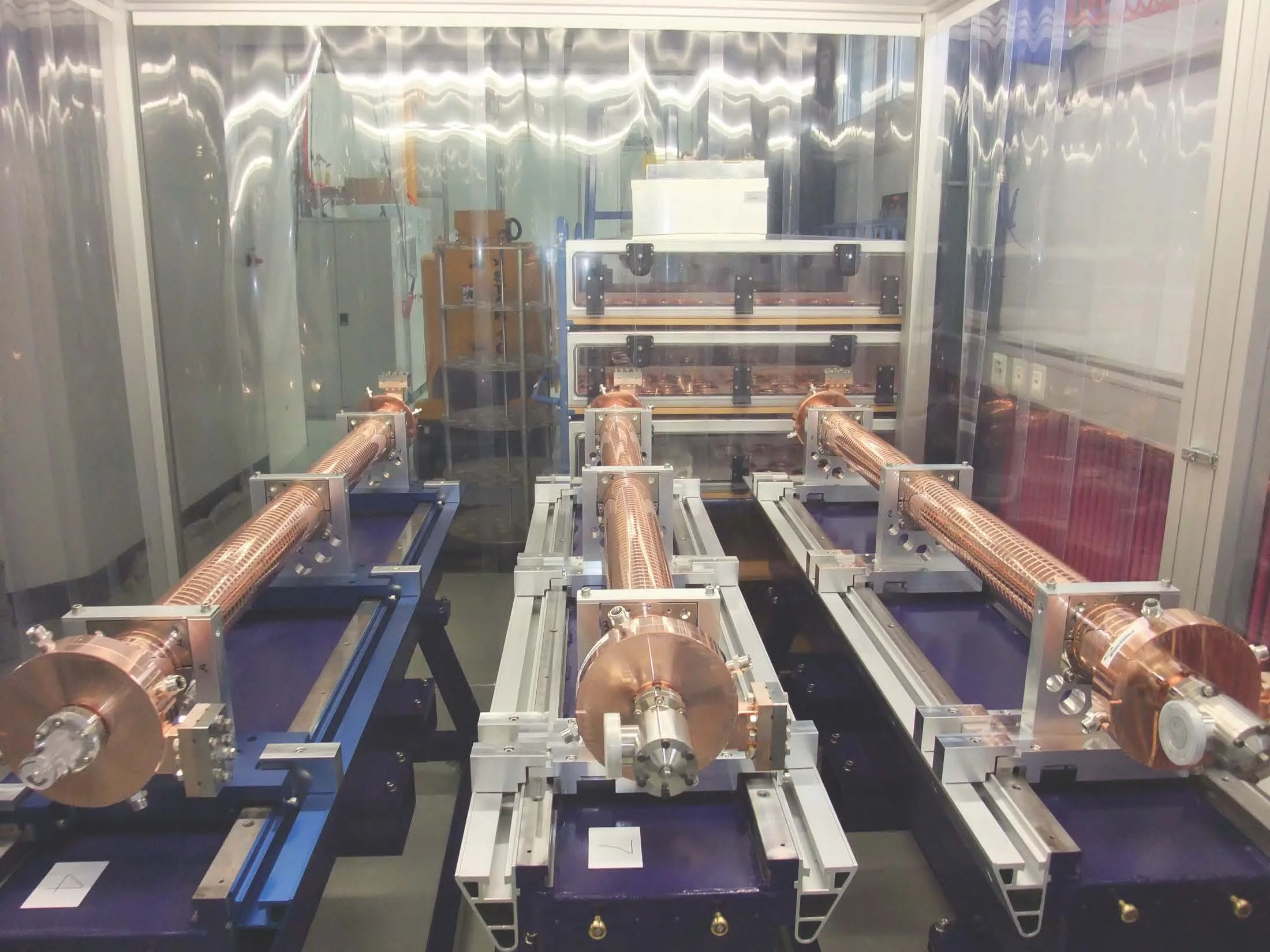

A total of 104 C-band accelerating structures will be needed for SwissFEL. Each of these structures is about 2 m long and consists out of 113 copper cells that are manufactured with micrometer precision using ultra-precision diamond machining, which results in mirror-like surfaces. The main components are the couplers at the input and the output of the structure, and the copper disks. For both, couplers and disks, the series production was successfully launched at the end of 2014. Since then the Dutch company VDL and TEL Mechatronics in Trübbach, Switzerland, delivered already many sets of couplers and accelerating disks, respectively.

The copper parts are then further processed at PSI in a special installation in the AMI-workshop. This involves a cleaning of the parts, a heat treatment, and several brazing steps. The individual parts are then combined to a complete structure using a special stacking robot. After this, a brazing of the structure takes place in a big vacuum brazing furnace. The verification of the proper functioning of a completed structure then includes micrometer-precise surveying, vacuum leak tests, and a number of RF measurements in which the field profile and other RF properties are measured.

In the meanwhile, a total of 15 accelerating structures have been brazed at PSI, currently, every week a new structure is completed.

Reference: Florian Löhl; florian.löhl@psi.ch; Paul Scherrer Institut, CH-5232 Villigen PSI, Switzerland