In order to tackle its main responsibilities, AHL must maintain, upgrade and develop two types of specific infrastructure:

- the safety infrastructure of the hot laboratory

- the technical and scientific infrastructure needed for the manipulation, characterization and analysis of radioactive materials.

Operation of HOTLAB

The Hot laboratory operation group is responsible for the safety and security related infrastructure of the laboratory.An extensive safety infrastructure is necessary for the reliable examination of highly radioactive materials.

This includes:

- An uninterrupted power supply.

- A complex ventilation system maintaining several low pressure levels.

- Waste air and water cleaning systems.

- Conditioning devices for liquid and solid waste.

- Radioactivity monitoring devices.

- A fission material bookkeeping system in order to avoid criticality accidents.

- Safety devices against sabotage and theft of nuclear material.

- A control room to supervise and operate the laboratory.

Hot Cell Experiments

The Hot Cell Experiments group operates the hot cell line for research on nuclear fuel rods, for material testing and mechanical material processing.

Manipulators are being operated through concrete walls of 1 meter in thickness.

Manipulators are being operated through concrete walls of 1 meter in thickness.

Preparative and analytical infrastructure

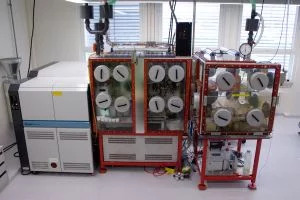

The investigation methods applied for the preparation and analysis of radioactive materials are very similar to the one used in standard chemical laboratories for nonradioactive samples.

However, the sample handling and preparation requires complex remote controlled operations and the analysis instruments often have to be shielded.

Increasingly, material analysis is based on instrumental techniques, and consequently the spatial distribution in very small solid state regions of micro- to nanometers is becoming as important as the concentration and isotopic analysis of main and trace elements (in solid and liquid samples). The mechanical properties of the material can also be strongly altered by irradiation with energetic particles. Several different machines are installed in the hot laboratory to perform various mechanical tests under different environmental conditions (temperature, pressure and atmosphere).

PIEs are mostly related to Swiss light water reactor (LWR), which are including investigations on the complete fuel rod system. Also in the international world, OFA act on PIE activities with different partners.

In the field of research activities OFA collaborates predominantly with internal PSI organizations. Swissnuclear (SN) and the European Community (EC) are predominantly backers for projects related to safety issues and vendors questions in the field of new fuel types and cladding tube behavior at different service conditions in the reactors.

However, the sample handling and preparation requires complex remote controlled operations and the analysis instruments often have to be shielded.

Increasingly, material analysis is based on instrumental techniques, and consequently the spatial distribution in very small solid state regions of micro- to nanometers is becoming as important as the concentration and isotopic analysis of main and trace elements (in solid and liquid samples). The mechanical properties of the material can also be strongly altered by irradiation with energetic particles. Several different machines are installed in the hot laboratory to perform various mechanical tests under different environmental conditions (temperature, pressure and atmosphere).

Surface and solid state analysis

The surface and solid state analysis (OFA) group (one of the two analytical groups of the division HOTLAB) operates a couple of analytical tools to examine the surface of radioactive material during post irradiation examination (PIE) and research projects.PIEs are mostly related to Swiss light water reactor (LWR), which are including investigations on the complete fuel rod system. Also in the international world, OFA act on PIE activities with different partners.

In the field of research activities OFA collaborates predominantly with internal PSI organizations. Swissnuclear (SN) and the European Community (EC) are predominantly backers for projects related to safety issues and vendors questions in the field of new fuel types and cladding tube behavior at different service conditions in the reactors.

Isotope and element analysis

The isotope and elementte analysis group operates a couple of analytical tools to examine isotopes and elements of radioactive material.

The most important tool is the ICP-MS, but also other tool are used.

The most important tool is the ICP-MS, but also other tool are used.