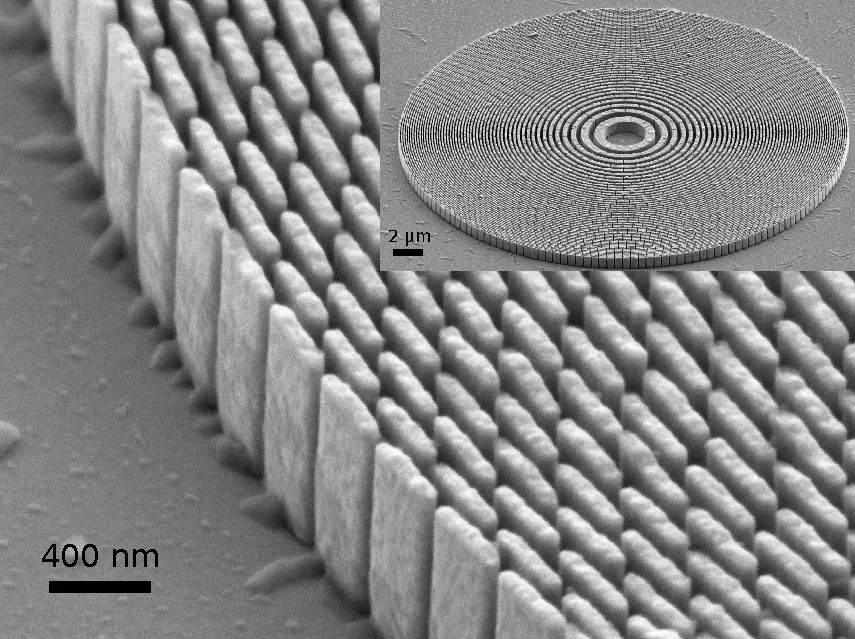

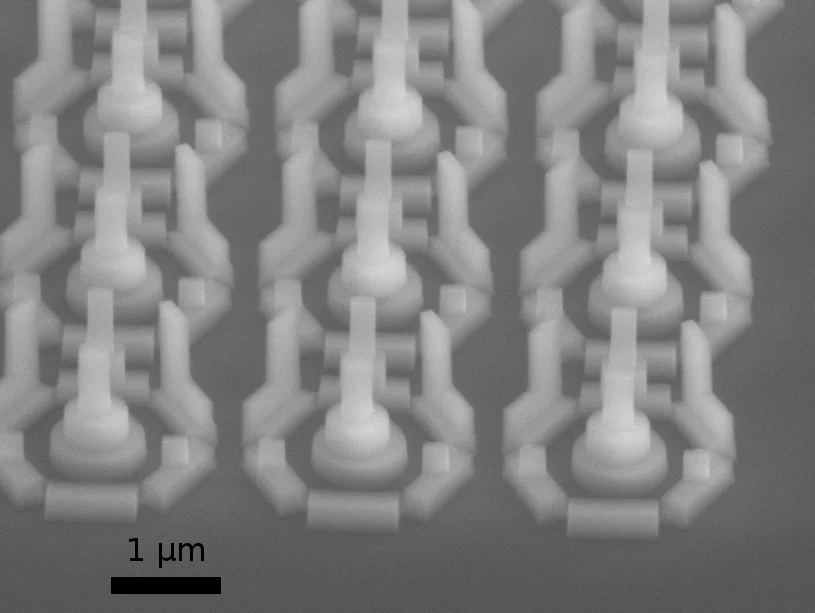

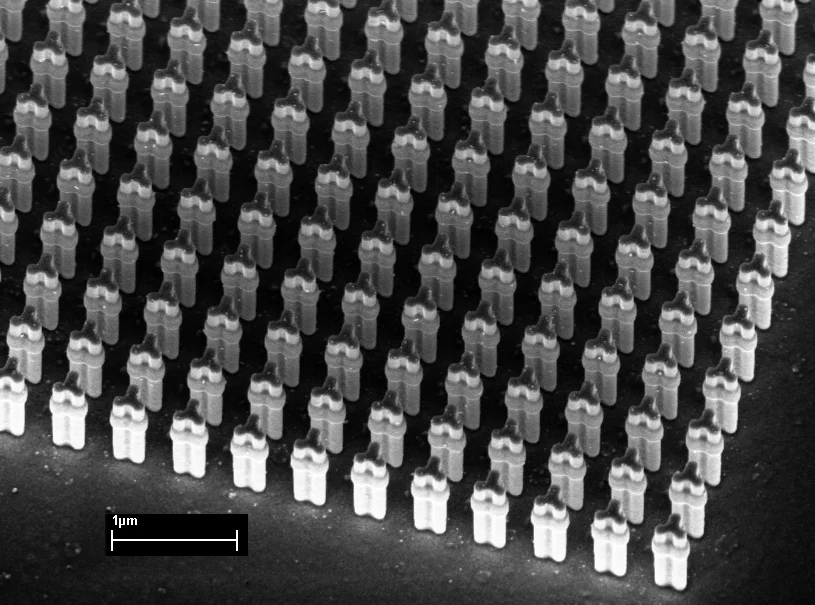

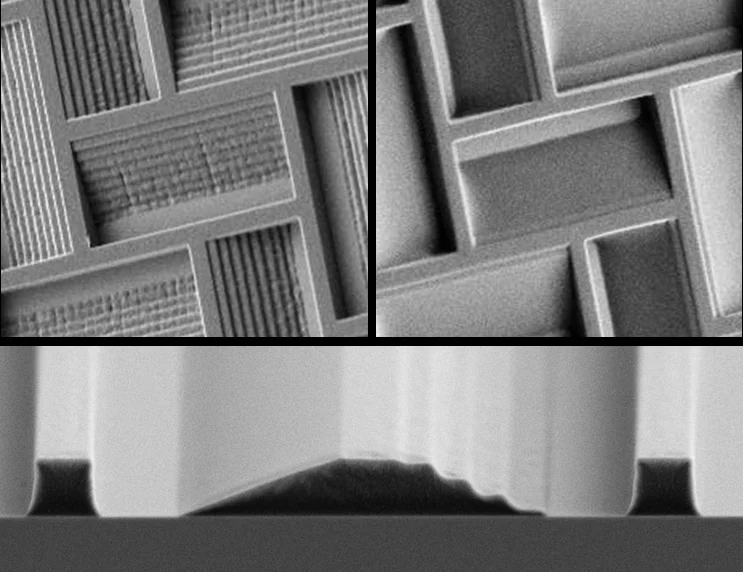

Direct write e-beam lithography tools at LMN provide a variety of powerful techniques for the lateral as well as three-dimensional pattern transfer with the resolution down to 10 nm. Compared to other nanostructuring methods, it stands out for a high level of flexibility and reasonably high patterning speed.

Vistec EBPG 5000PlusES

Vistec EBPG 5000Plus e-beam lithography tool is in operation since March 2009. It is installed in a dedicated cleanroom of class 100 with high precision temperature control at 21 ± 0.1° C. This is a prerequisite for the minimization of thermal drift in the electron optics, and thus, for the excellent performance of the system.

The main characteristics of the tool are:

- It is a vector-scan direct write tool with a Gaussian shaped beam. The beam scanning is controlled by combination of two deflection systems. Thus, the maximum writing field size of 512×512 µm² in conjunction with the beam stepping frequencies up to 50 MHz are achievable.

- The spot can be focused to less than 5 nm in diameter. Owing to the wide range of available beam currents (200 pA – 200 nA), the high-throughput as well as high-resolution exposures are possible.

- It is operated at 100 keV acceleration voltage. Up to several micrometers thick layers of e-beam resist can be exposed with small forward scattering.

- Wafers with diameter up to 150 mm and mask blanks up to 5×5 sq. inch can be processed.

- The overlay precision (mean + 3σ) is below 40 nm for the largest and 20 nm for smaller (100×100 µm²) write fields.

- For the conversion of the CAD patterns into machine specific format, including proximity effect correction (PEC), a special software solution – Layout BEAMER – is used. In some special cases, a direct coding of the beam movement is advantageous, which allows up to speed up remarkable the exposure or improve further the resolution.