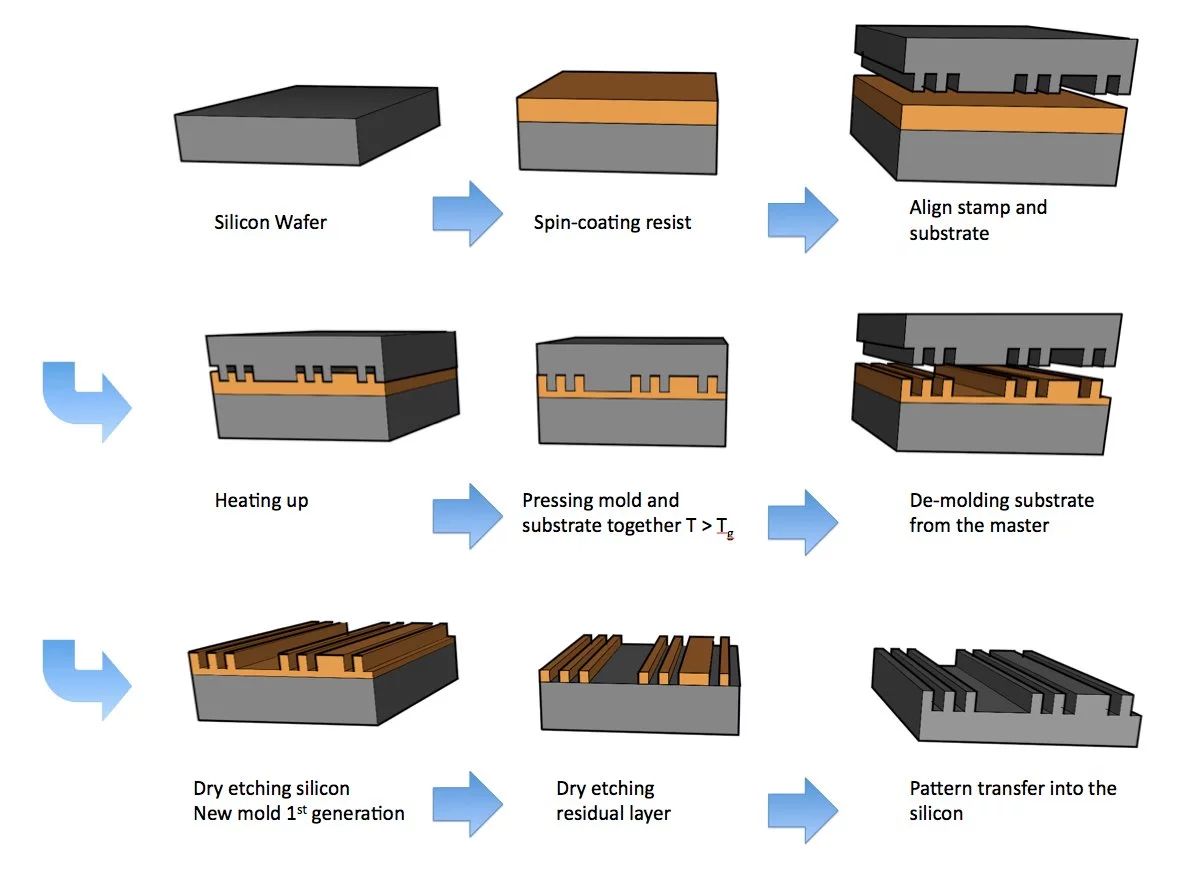

Nanoimprint Lithography (NIL) is a novel technique for the fabrication of nanostructures on large surfaces. The method is based on the excellent replication fidelity obtained with polymers. Once a solid stamp with a nanorelief on the surface is fabricated it can be used for the replication of many identical surface patterns. It therefore circumvents many limitations of conventional photolithography. In PSI we use both thermal NIL into various thermoplastic materials and UV-assisted NIL, e.g. for the fabrication of stamp copies.

The process chain mainly consists of the three steps:

- Align substrate, resist and stamp

- Imprint into polymer film

- Pattern transfer into substrate

The pattern transfer is often necessary if the imprinted polymer is not directly used as a functional material, but for patterning a large area substrate such as a silicon wafer or magnetic disc. It is therefore able to replace common high resolution lithography which is either costly or not able to pattern complex structures with 3D surface topographies.

J. Vac. Sci. Technol. B 26(2), 458-480 (2008)

Helmut Schift

NaPa Library of Processes

editor H.Schift, published by the NaPa-consortium

first edition (2008) ISBN 978-3-00-024396-7, second edition (2012)

Free download: NaPa Library of Processes

Nanoimprint lithography - patterning resists using molding

H. Schift and A. Kristensen

Handbook of Nanotechnology, Chapter (Part A/9), third edition, revised and extended, 2010

Springer Verlag Berlin Heidelberg, Germany. ISBN: 978-3-642-02524-2

Publications

Nanoimprint lithography: An old story in modern times? A reviewJ. Vac. Sci. Technol. B 26(2), 458-480 (2008)

Helmut Schift

NaPa Library of Processes

editor H.Schift, published by the NaPa-consortium

first edition (2008) ISBN 978-3-00-024396-7, second edition (2012)

Free download: NaPa Library of Processes

Nanoimprint lithography - patterning resists using molding

H. Schift and A. Kristensen

Handbook of Nanotechnology, Chapter (Part A/9), third edition, revised and extended, 2010

Springer Verlag Berlin Heidelberg, Germany. ISBN: 978-3-642-02524-2