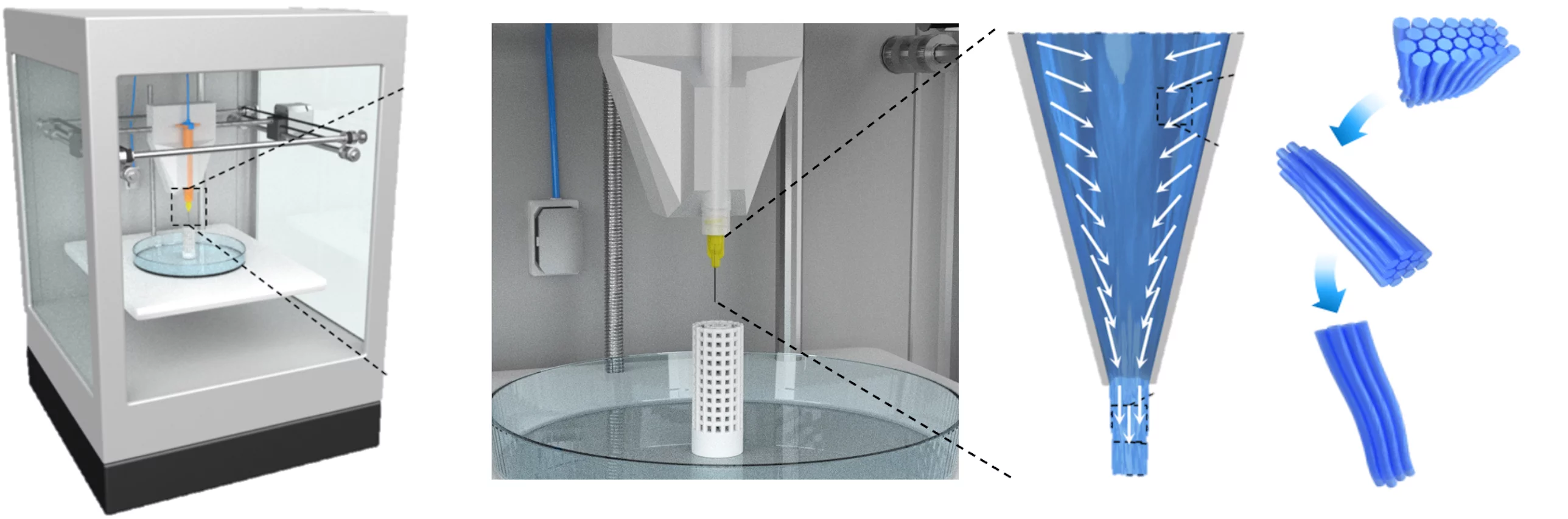

In order to create hierarchical structures with a controlled architecture, flow-fields can be used to induce an alignment of nanostructures, as used in ink-based 3D printing or extrusion processes. We use microfluidic devices to simulate processes within the 3D printing nozzles and use optical birefringence and scanning small-angle X-ray scattering (SAXS) to map the nanostructural arrangement in flow. SAXS measurements are also combined with in-situ 3D printing, investigating the material directly after extrusion.

Structural evolution and alignment of lyotropic liquid crystal in flow

Pluronic based lyotropic liquid crystals can form various self-assembly structures, such as hexagonal or lamellar phase. In order to control the organization of those nanostructures within macroscopic objects, 3D printing can be used. We use a combination of SAXS and microfluidic devices to study the arrangement in confined flow mimicking the 3D printing nozzle as well as in-situ 3D printing experiments.

This project is conducted at Chalmers University of Technology.

Alignment of nanocellulose in fluidic four roll mill

The fluidic-four roll mill allows to study comblex flow fields ranging from pure extensional flow over shear flow to rotation and can be combined with birefringence microscopy or scanning SAXS. We are using the device to investigate the effect of different flow fields, concentration, aspect ratio and interaction forces of cellulose-based nanomaterials

This project is conducted at Chalmers University of Technology, Gothenburg Sweden, in close collaboration with researchers from UC Santa Barbara.