Mapping crystallite orientation in bulk polycrystals

A new experimental technique allows the orientation distribution of small-grained polycrystal materials to me mapped in 3D.

Rethinking 3D Printing for ceramics

Using a powerful combination of in-situ X-ray imaging and high-fidelity simulations, researchers uncover how alumina behaves under laser-based 3D printing—paving the way for more reliable ceramic additive manufacturing.

Texture and residual stress evolution during 3D printing

Discover how advanced neutron diffraction sheds light on the evolution of stress and texture in 3D-printed duplex stainless steel.

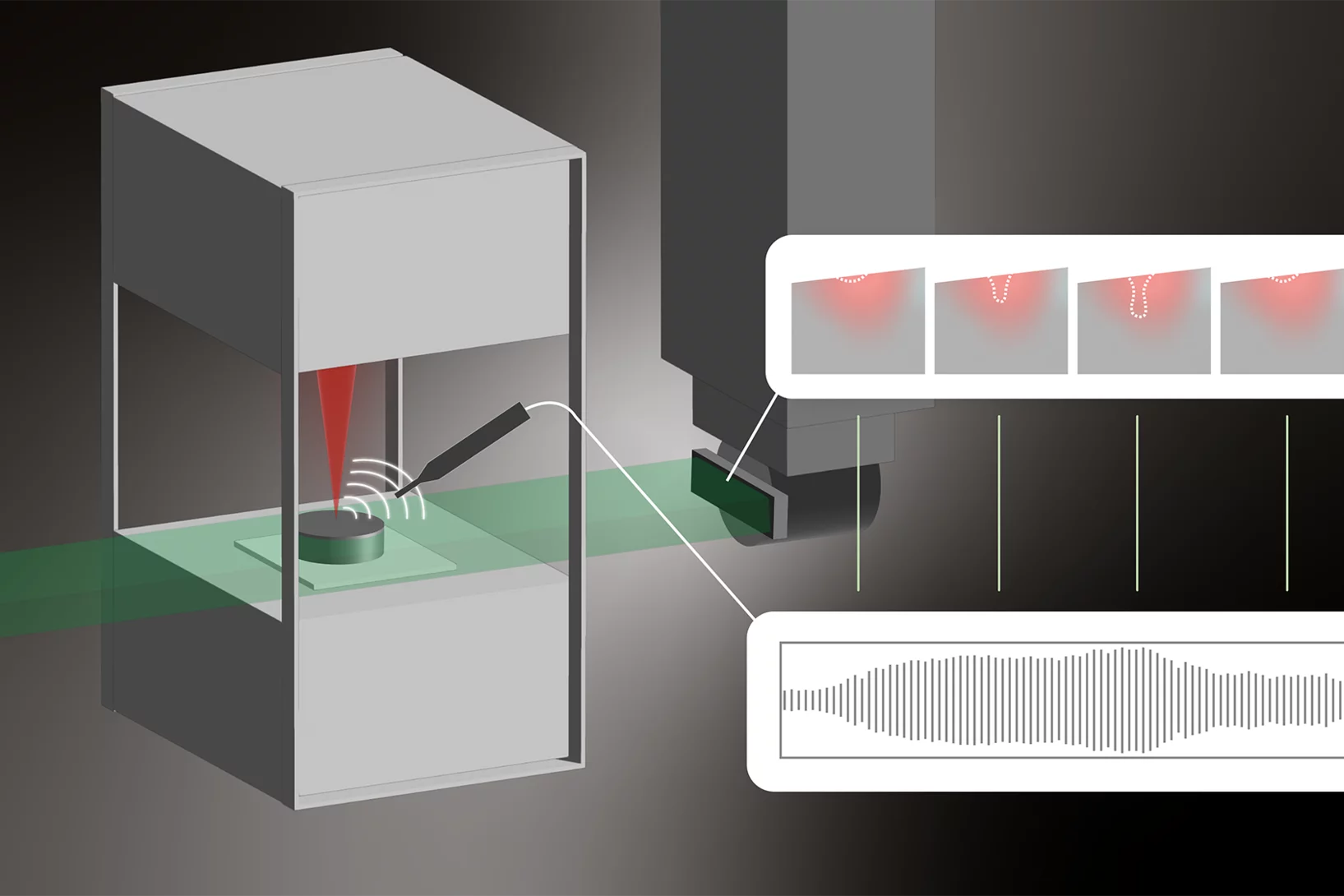

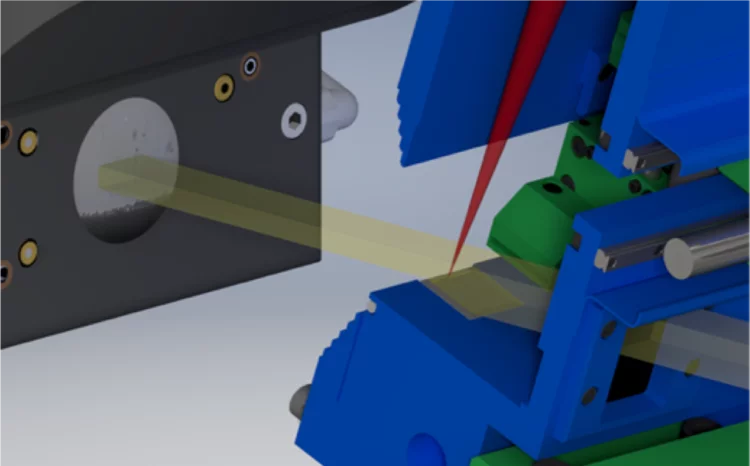

Operando Neutron Characterization During 3D Printing

A new laser powder bed fusion device enables real-time neutron diffraction and imaging, providing detailed insights into structural evolution, defect formation, and temperature mapping during metal additive manufacturing.

Mitigating Cracks in Multi-Material Printing

Integrating metallic powders with thin foils in laser powder bed fusion can reduce interfacial cracks and improve microstructure quality in titanium-aluminum multi-material printing.

Acoustic emission signature of a martensitic transformation

Acoustic emission monitoring in 3D printing: real-time insights into martensitic phase transformations and crack formation.

The Tipping Point!

Exciting to see that some of our research on Narwhal tusk made it into an educational videogame about climate change in the Arctic and its impact on some of its inhabitants!

Observing laser-induced recrystallization

Synchrotron X-ray diffraction sheds light on laser-induced local recrystallization .

Listening for Defects as They Happen

Experiments at the Swiss Light Source SLS help resolve a long-standing debate surrounding metal 3D laser printing.

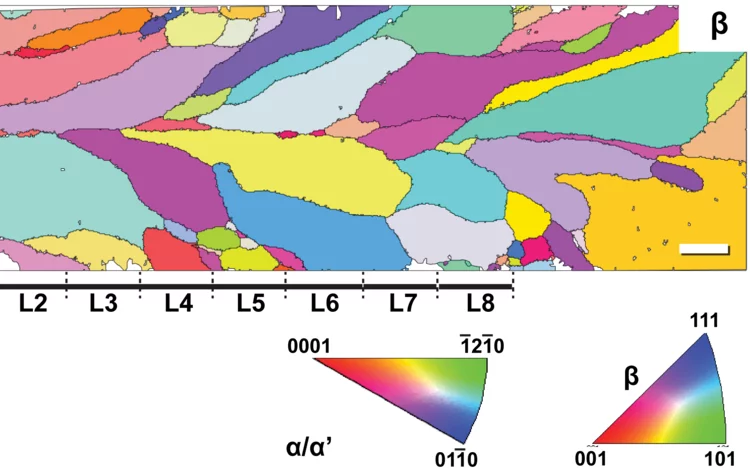

Microstructural control of additively manufactured Ti-6Al-4V

In-situ Selective Laser Heat treatment is applied to induce martensite decomposition in Ti-6Al-4V

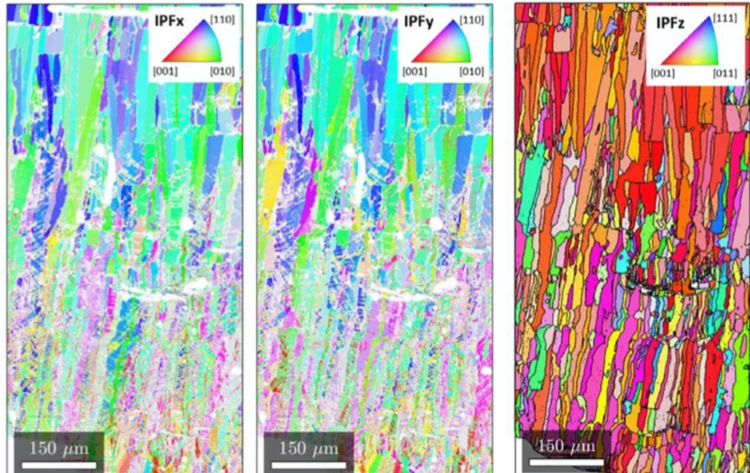

Additive manufacturing of alloys with programmable microstructure and properties

Using laser powder bed fusion (LPBF) technology, we devise special processing strategies to ‘program’ the thermal stability of the as-printed alloy, such that it is possible to decide, a priori, how the material’s microstructure will evolve upon heat treatment

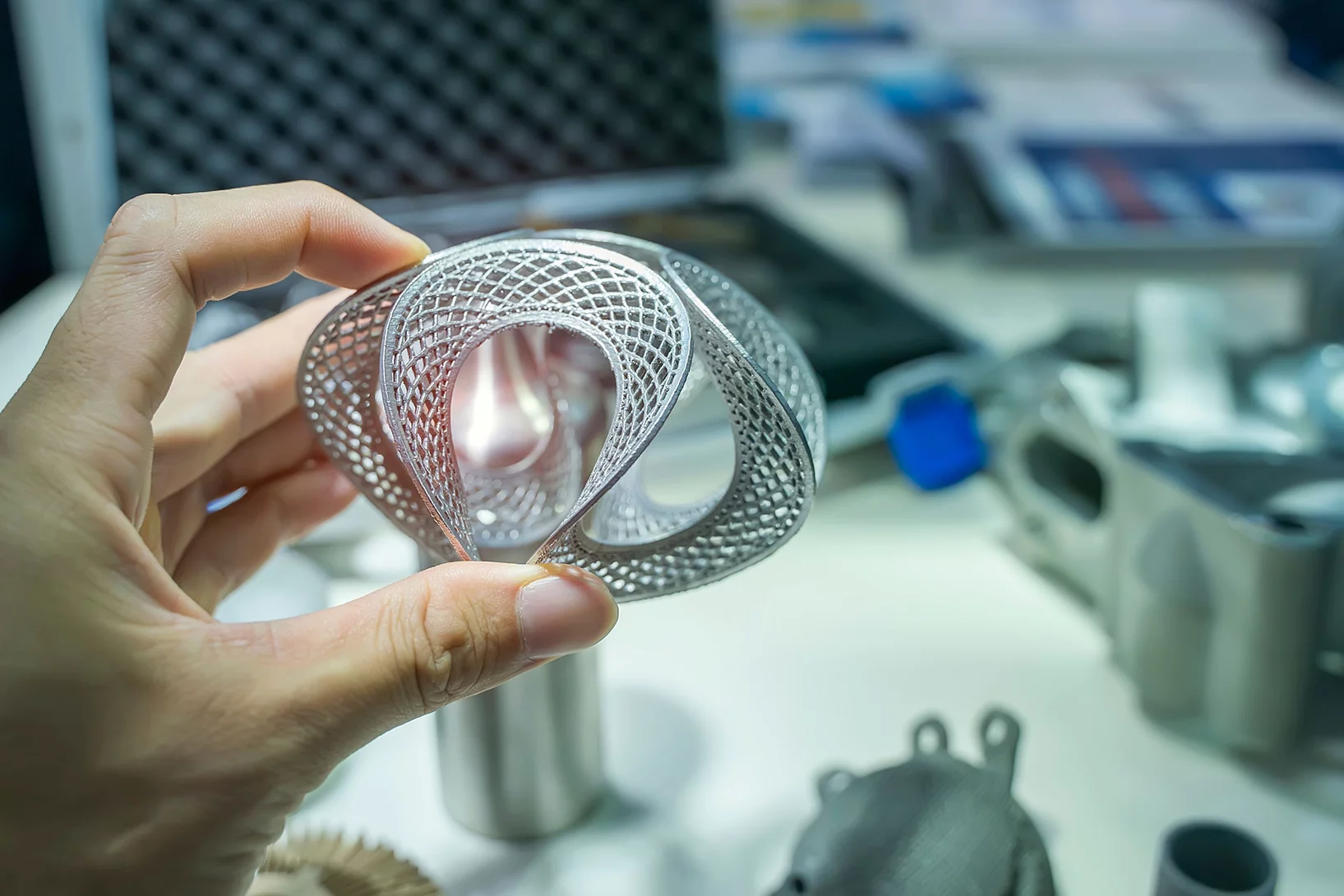

3-D-Einblicke in neuartiges Fertigungsverfahren

Mit 3-D-Druck komplexe Formen herstellen

On the trail of blue bones

The bones of the tree hollow toad tree frog are turquoise blue. Our team is currently investigating the nanostructure of the bone and its significance for the frog.

MUMOTT V1.0 released!

We are happy to announce the release of MUMOTT (multi-modal tensor tomography) 1.0, an all-Python package for the analysis of tensor tomography measurements!

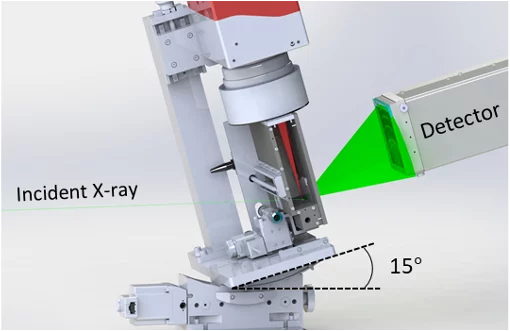

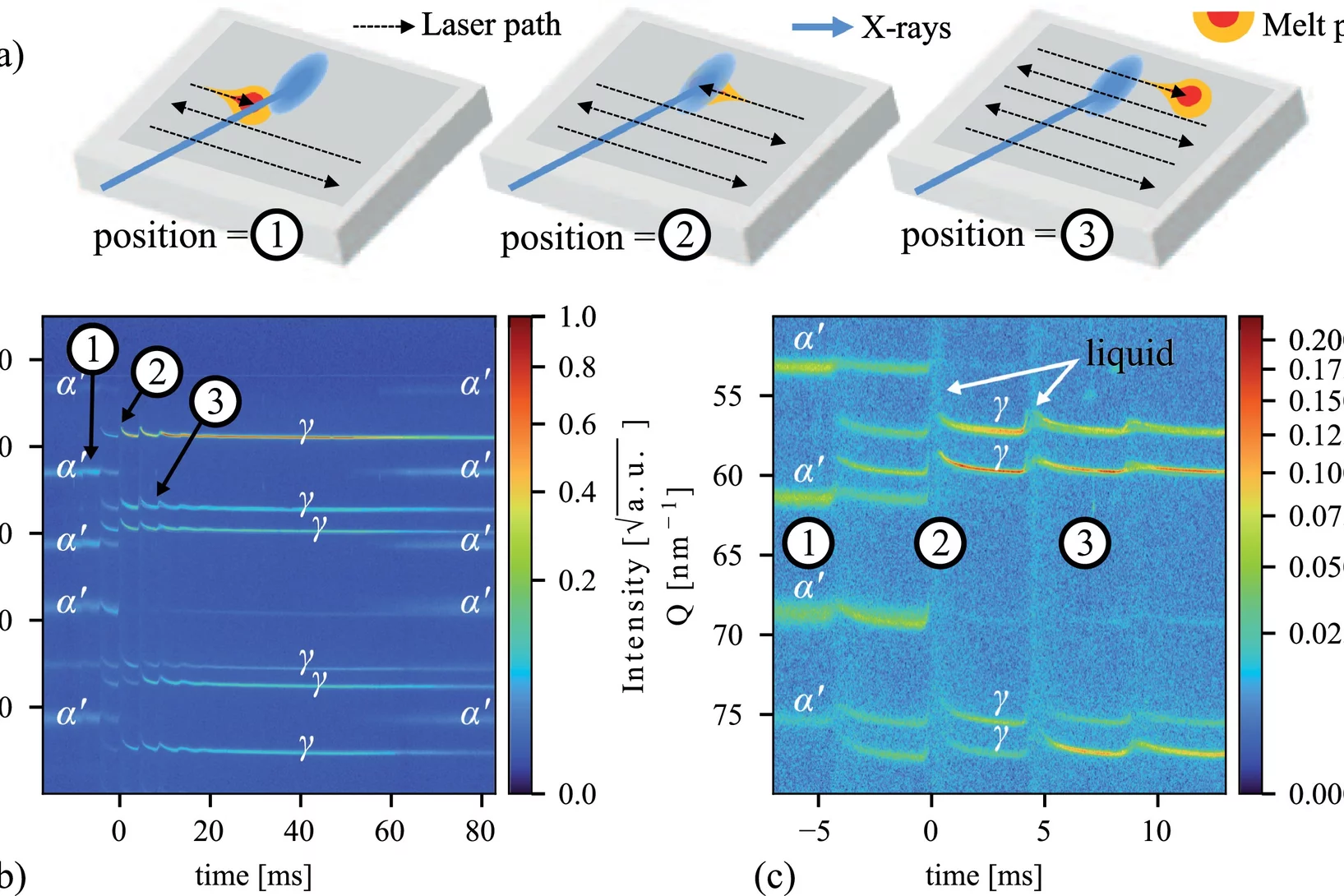

A close look at temperature profiles during laser 3D printing

Operando X-ray diffraction was used to measure process zone temperatures in laser powder bed fusion and compared with finite element simulations.

X-rays make 3D metal printing more predictable

Insights into the microscopic details of 3D printing from the Swiss Light Source SLS could propel the technology toward wider application

Solidification modes during additive manufacturing

The thermal conditions during laser-based additive manufacturing are inferred from high-speed X-ray diffraction data and can be linked to a model for rapid solidification.

Thermal cycling during 3D laser printing

High-speed in situ X-ray diffraction is used to measure temperature profiles and cooling rates during 3D printing of a a Ti-6Al-4V single-track wall.

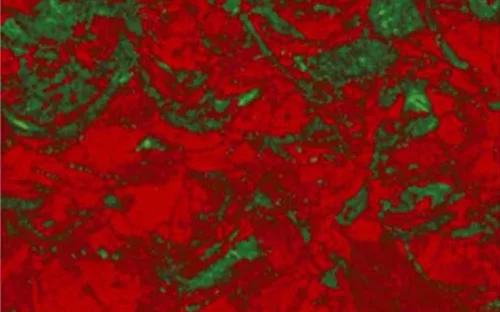

In situ alloying during additive manufacturing

In situ alloying is an effective method to engineer microstructures of additively manufactured Ti6Al4V3Fe alloys.

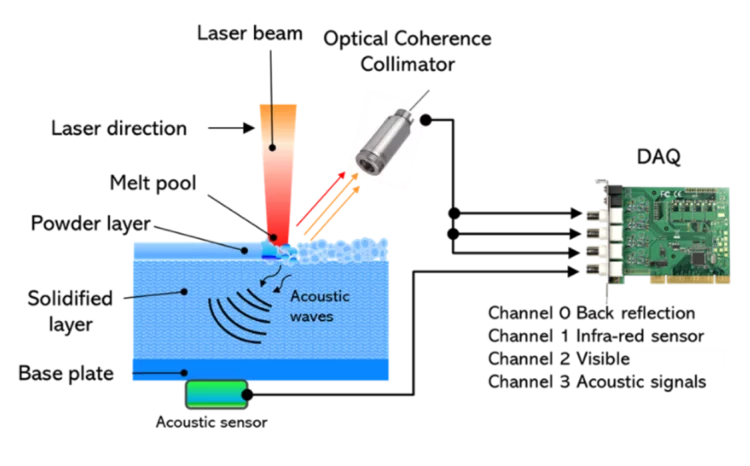

Deep learning-based monitoring of laser powder bed fusion processes

We present a novel monitoring strategy for 3D print processes that consists of developing and training a hybrid machine learning model that can classify regimes across different time scales based on heterogeneous sensing data.

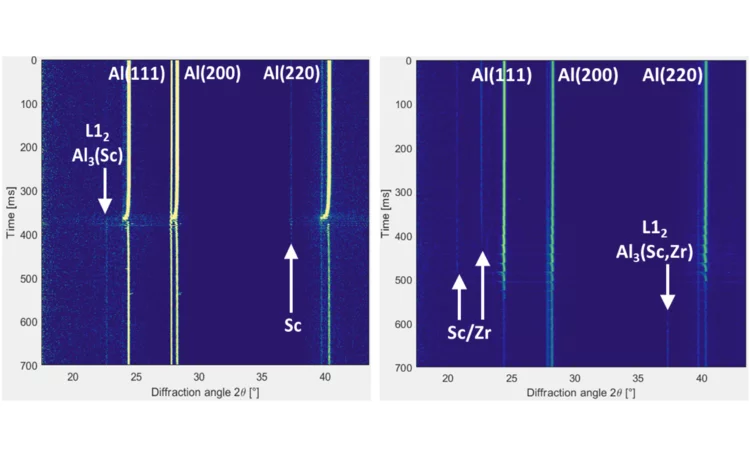

Thermal and phase evolution during laser powder bed fusion of Al-Sc-Zr elemental powder blends

The reaction of elemental scandium and zirconium powders with liquid aluminum is observed directly via operando X-ray diffraction during laser 3D printing. This work demonstrates that elemental blends can be used to create fine-grained crack-free Al-alloys and highlights the importance of feature size.

Direct observation of crack formation mechanisms with operando Laser Powder Bed Fusion X-ray radiography

Operando high-speed X-ray radiography experiments reveal the cracking mechanism during 3D laser printing of a Ni superalloy.

Understanding variant selection and texture in additively manufactured red-gold alloys

Synchrotron X-ray diffraction experiments reveal the presence of a non- negligible amount of tetragonal phase in 3D printed red-gold samples.

Ground-breaking technology development recognised

PSI researchers win the international Innovation Award on Synchrotron Radiation for 3D mapping of nanoscopic details in macroscopic specimens, such as bone.