Additive manufacturing, also known as 3D printing, is a bottom-up approach in which a part is manufactured layer by layer from a 3D computer model. In the SMAM group, we study the influence of the processing parameters on the microstructural evolution during the printing process. This is achieved by fast operando X-ray diffraction, radiography and small-angle scattering, combined with state-of-the-art post-processing characterisation techniques.

Laser powder bed fusion is a very complex technique, with many variables. To ensure an optimal build quality, in situ process monitoring is crucial. In a SNF funded Sinergia project, the SMAM group, in collaboration with research groups from EPFL, EMPA and PSI aim to develop an online monitoring strategy for additive manufacturing.

Laser powder-bed fusion (LPBF) is the most widely used additive manufacturing process for monolithic metal parts. Many applications would greatly profit if more then one materials could be co-processed in the powder bed. Besides offering a much wider design space, multi-material LPBF would allow for producing functional parts without joining and assembly operations, and add 'function for free' as a new dimension to LPBF. In this project, we explore laser exposure strategies that allow controlled 3D printing of multi-material.

Laser powder bed fusion has great potential to design advanced alloys in situ during the printing process. We explore by operando X-ray diffraction the phase evolution during 3D printing of powder mixtures.

-

Navarre C, Van Petegem S, Schlenger L, Cayron C, Hamidi-Nasab M, Esmaeilzadeh R, et al.

Monitoring of laser-induced fast recrystallization in SS-316L through synchrotron X-ray diffraction

Materials and Design. 2024; 238: 112628 (14 pp.). https://doi.org/10.1016/j.matdes.2023.112628

DORA PSI -

Yang J, Schlenger LM, Nasab MH, Van Petegem S, Marone F, Logé RE, et al.

Experimental quantification of inward Marangoni convection and its impact on keyhole threshold in laser powder bed fusion of stainless steel

Additive Manufacturing. 2024; 84: 104092 (11 pp.). https://doi.org/10.1016/j.addma.2024.104092

DORA PSI -

de Formanoir C, Hamidi Nasab M, Schlenger L, Van Petegem S, Masinelli G, Marone F, et al.

Healing of keyhole porosity by means of defocused laser beam remelting: Operando observation by X-ray imaging and acoustic emission-based detection

Additive Manufacturing. 2024; 79: 103880 (18 pp.). https://doi.org/10.1016/j.addma.2023.103880

DORA PSI -

Esmaeilzadeh R, Hamidi-Nasab M, de Formanoir C, Schlenger L, Van Petegem S, Navarre C, et al.

In-situ selective laser heat treatment for microstructural control of additively manufactured Ti-6Al-4V

Additive Manufacturing. 2023; 78: 103882 (14 pp.). https://doi.org/10.1016/j.addma.2023.103882

DORA PSI -

Hamidi Nasab M, Masinelli G, de Formanoir C, Schlenger L, Van Petegem S, Esmaeilzadeh R, et al.

Harmonizing sound and light: X-ray imaging unveils acoustic signatures of stochastic inter-regime instabilities during laser melting

Nature Communications. 2023; 14: 8008 (14 pp.). https://doi.org/10.1038/s41467-023-43371-3

DORA PSI -

Gao S, Li Z, Van Petegem S, Ge J, Goel S, Vas JV, et al.

Additive manufacturing of alloys with programmable microstructure and properties

Nature Communications. 2023; 14(1): 6752 (11 pp.). https://doi.org/10.1038/s41467-023-42326-y

DORA PSI -

Gh Ghanbari P, Markovic P, Van Petegem S, Makowska MG, Wrobel R, Mayer T, et al.

A close look at temperature profiles during laser powder bed fusion using operando X-ray diffraction and finite element simulations

Additive Manufacturing Letters. 2023; 6: 100150 (9 pp.). https://doi.org/10.1016/j.addlet.2023.100150

DORA PSI -

König H-H, Holländer Pettersson N, Durga A, Van Petegem S, Grolimund D, Chuang AC, et al.

Solidification modes during additive manufacturing of steel revealed by high-speed X-ray diffraction

Acta Materialia. 2023; 246: 118713 (11 pp.). https://doi.org/10.1016/j.actamat.2023.118713

DORA PSI -

Chen M, Van Petegem S, Zou Z, Simonelli M, Tse YY, Chang CST, et al.

Microstructural engineering of a dual-phase Ti-Al-V-Fe alloy via in situ alloying during laser powder bed fusion

Additive Manufacturing. 2022; 59: 103173 (10 pp.). https://doi.org/10.1016/j.addma.2022.103173

DORA PSI -

Chen M, Simonelli M, Van Petegem S, Tse YY, Chang CST, Makowska MG, et al.

A quantitative study of thermal cycling along the build direction of Ti-6Al-4V produced by laser powder bed fusion

Materials and Design. 2023; 225: 111458 (11 pp.). https://doi.org/10.1016/j.matdes.2022.111458

DORA PSI -

Pandiyan V, Masinelli G, Claire N, Le-Quang T, Hamidi-Nasab M, de Formanoir C, et al.

Deep learning-based monitoring of laser powder bed fusion process on variable time-scales using heterogeneous sensing and operando X-ray radiography guidance

Additive Manufacturing. 2022; 58: 103007 (15 pp.). https://doi.org/10.1016/j.addma.2022.103007

DORA PSI -

Glerum JA, Hocine S, Chang CST, Kenel C, Van Petegem S, Casati N, et al.

Operando X-ray diffraction study of thermal and phase evolution during laser powder bed fusion of Al-Sc-Zr elemental powder blends

Additive Manufacturing. 2022; 55: 102806 (12 pp.). https://doi.org/10.1016/j.addma.2022.102806

DORA PSI -

Ghasemi-Tabasi H, de Formanoir C, Van Petegem S, Jhabvala J, Hocine S, Boillat E, et al.

Direct observation of crack formation mechanisms with operando laser powder bed fusion X-ray imaging

Additive Manufacturing. 2022; 51: 102619 (11 pp.). https://doi.org/10.1016/j.addma.2022.102619

DORA PSI -

Hocine S, Van Swygenhoven H, Van Petegem S

Verification of selective laser melting heat source models with operando X-ray diffraction data

Additive Manufacturing. 2021; 37: 101747 (16 pp.). https://doi.org/10.1016/j.addma.2020.101747

DORA PSI -

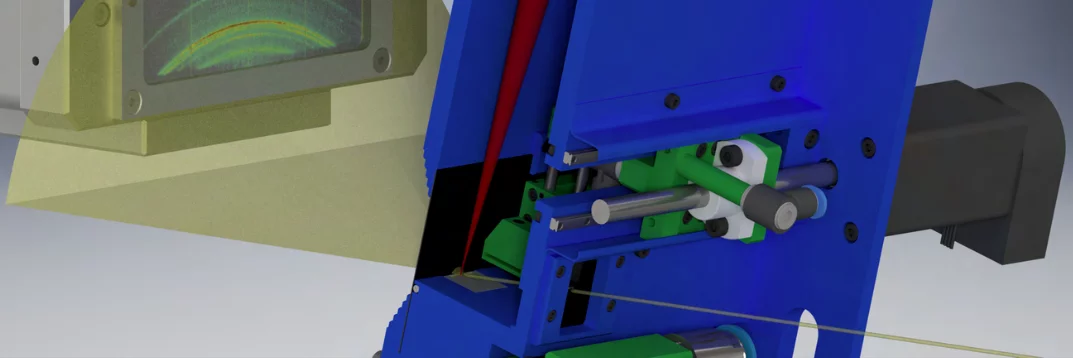

Hocine S, Van Petegem S, Frommherz U, Tinti G, Casati N, Grolimund D, et al.

A miniaturized selective laser melting device for operando X-ray diffraction studies

Additive Manufacturing. 2020; 34: 101194 (9 pp.). https://doi.org/10.1016/j.addma.2020.101194

DORA PSI -

Hocine S, Van Swygenhoven H, Van Petegem S, Chang CST, Maimaitiyili T, Tinti G, et al.

Operando X-ray diffraction during laser 3D printing

Materials Today. 2020; 34: 30-40. https://doi.org/10.1016/j.mattod.2019.10.001

DORA PSI

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials

Photon Science Division

Paul Scherrer Institute

Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537

E-mail: steven.vanpetegem@psi.ch