A new laser powder bed fusion device enables real-time neutron diffraction and imaging, providing detailed insights into structural evolution, defect formation, and temperature mapping during metal additive manufacturing.

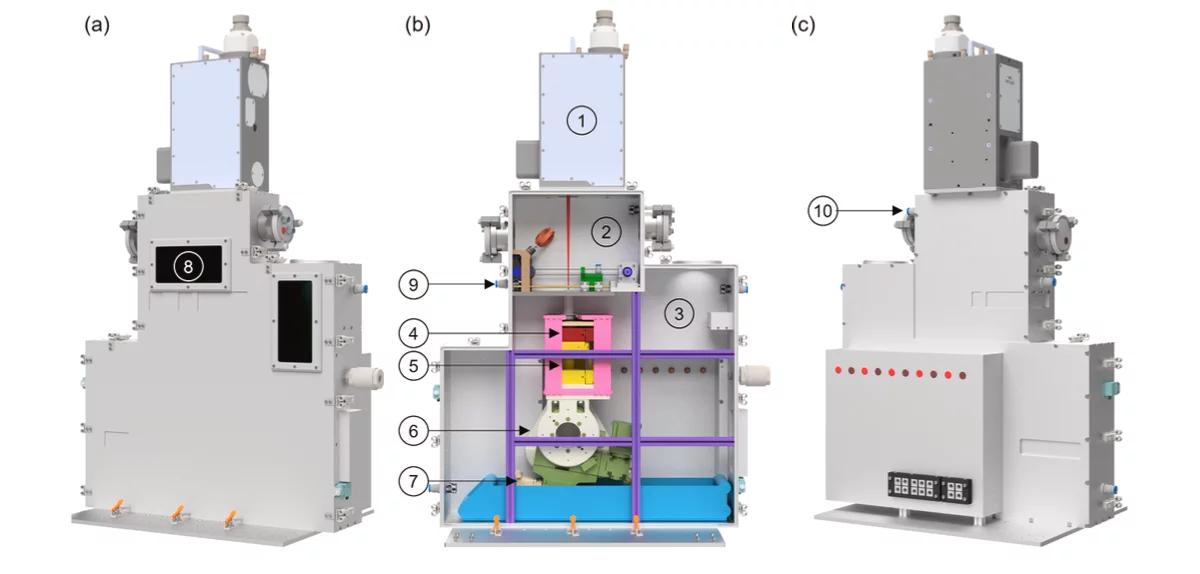

A new laser powder bed fusion device (n-SLM) was created to explore metal 3D printing processes in real-time using neutrons. This machine is smaller than standard industrial ones but allows similar printing while letting neutrons pass through the materials. It can be installed at different beamlines of the Swiss Spallation Neutron Source (SINQ). Scientists can use this setup to study how the structure and properties of metals evolve during printing, which is difficult to observe with other methods like X-rays.

With this device, researchers demonstrated how to monitor thermal strain and defects in real-time. For example, they followed the development of elastic strain in nickel-based superalloy IN713C during printing by analyzing neutron diffraction patterns. The results showed how heat affects strain without damaging the material. In another experiment, neutron imaging was used to track defects like cracks forming during the process. By changing printing settings, the team showed how to reduce such defects in the final product.

In addition, the device enables temperature and phase mapping during multi-material printing, such as combining stainless steel and copper alloys. By using a special neutron filter, researchers created temperature profiles of the material layers as they were printed. This helps to understand how heat spreads between different materials and influences their microstructure. These capabilities demonstrate the potential of the n-SLM device to improve 3D printing techniques and material quality for advanced applications.

Contact

Original publication

-

Sumarli S, Polatidis E, Malamud F, Van Petegem S, Busi M, Logé RE, et al.

A downsized laser powder bed fusion device for operando neutron studies: design and experiments

Additive Manufacturing. 2025; 98: 104654 (10 pp.). https://doi.org/10.1016/j.addma.2025.104654

DORA PSI