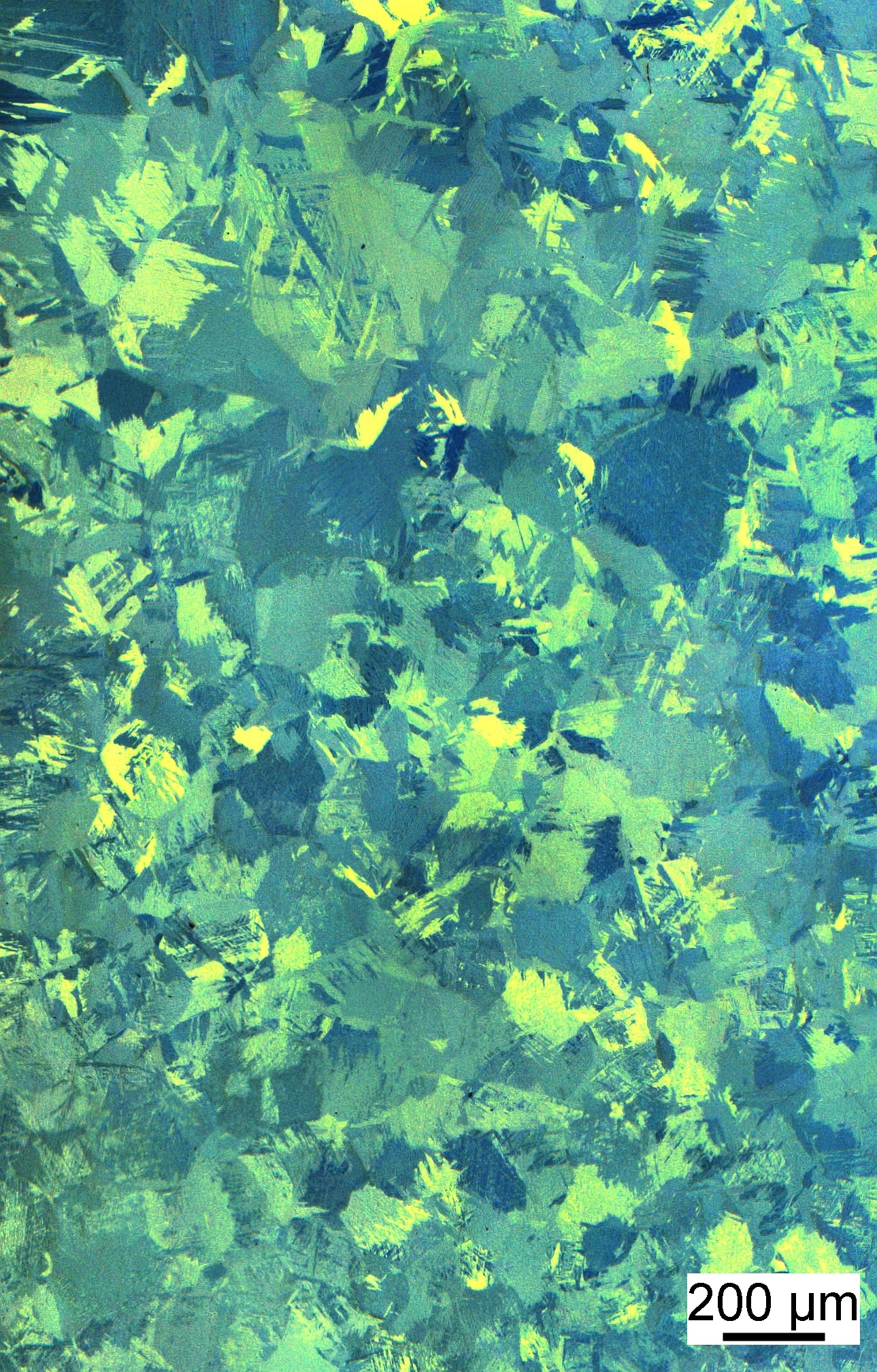

The metallographic analysis of weld seams using etching techniques and light microscopy is an essential method in quality assurance.

Etching makes microstructures visible, allowing the detection of otherwise unnoticed weaknesses.

These insights contribute to the optimization of welding techniques and provide valuable information about the heat-affected zones of welds.

Etching zirconium alloys is particularly challenging due to their high corrosion resistance and often requires different approaches compared to the metallographic etching of steels.

Methods involving hydrofluoric acid-based solutions or electrochemical techniques are disadvantageous from a safety perspective, difficult to apply in hot cells and glove boxes, and often do not yield the desired results.

By using less hazardous H₂O₂ and careful polishing, the microstructure of zirconium alloys was reproducibly and clearly visualized.