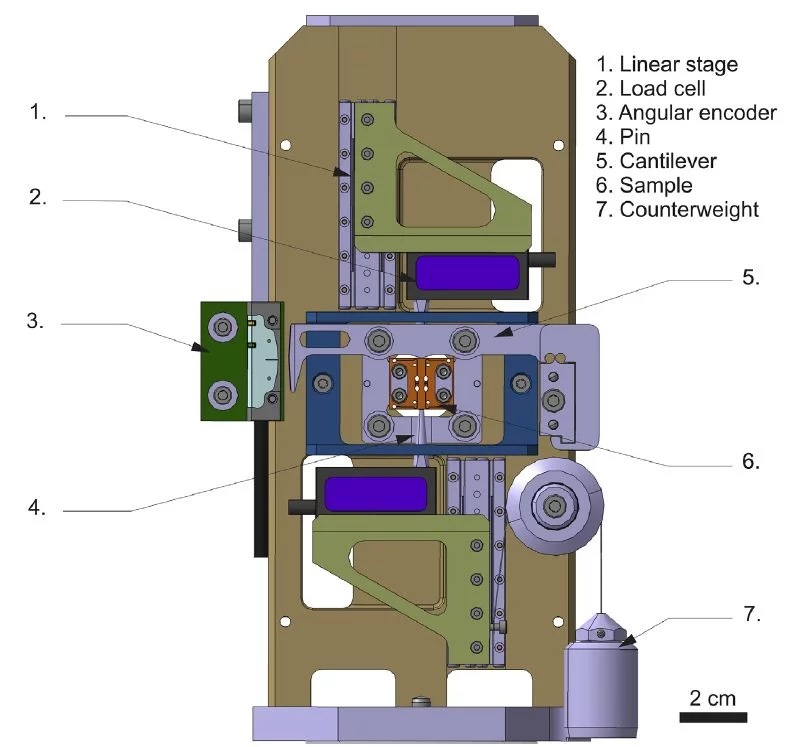

A dedicated miniaturized deformation rig has been built to apply reversible shear and to be compatible with in situ Laue micro-diffraction. It requires a rather complex sample geometry, where a single crystal is locally thinned down to x-ray beam transparency. Details on the sample geometry can be found here. The machine is controlled by an in-house written LabVIEW program. It allows to perform cyclic reverse shear at constant total strain or applied force.

More information on the device can be found here:

Following dislocation patterning during fatigue

Irastorza-Landa A, Van Swygenhoven H, Van Petegem S, Grilli N, Bollhalder A, Brandstetter S, Grolimund D

ACTA MATERIALIA 112, 184 (2016).

DOI: 10.1016/j.actamat.2016.04.011

Following dislocation patterning during fatigue

Irastorza-Landa A, Van Swygenhoven H, Van Petegem S, Grilli N, Bollhalder A, Brandstetter S, Grolimund D

ACTA MATERIALIA 112, 184 (2016).

DOI: 10.1016/j.actamat.2016.04.011

Technical details

| Displacement | ||

|---|---|---|

| Minimum step size | 5nm | |

| Maximum speed | 20mm/s | |

| Force | ||

| Maximum force | 7N | |

| Strain measurement | ||

| Method | Angular encoder combined with finite element modeling | |

| Maximum shear strain | ~1% | |

| Resolution | 0.01% | |

| Other specifications | ||

| Deformation modes | Reverse shear | |

| Control modes | Displacement, force | |

| Temperature | RT | |

| Size (L x W x H) | 200mm x 90mm x 150mm | |

| Weight | 1kg | |

| Compatible SLS beam lines | MicroXAS |