In Situ Diffraction during Mechanical Testing

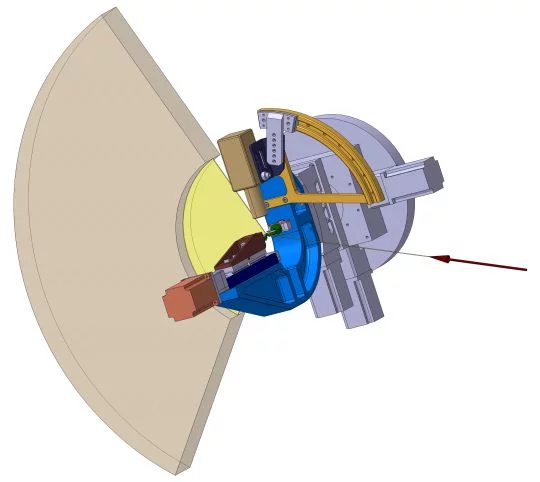

In situ mechanical testing during diffraction is one of the best-known in situ methods during which the microstructure of a device or component is investigated during exposure to stress and/or temperature. Such an experiment allows capturing footprints of the deformation mechanisms responsible for the changing microstructure. The following techniques have been developed over the course of the past 15 years:

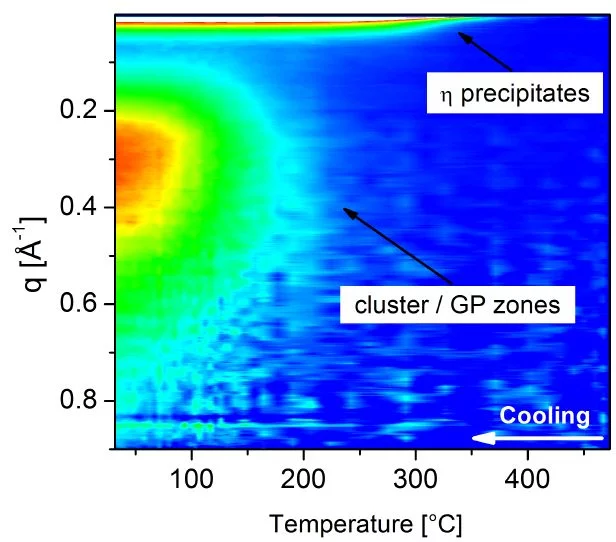

In Situ Fast Cooling

In situ synchrotron x-ray diffraction and small angle scattering are ideal techniques to investigate the kinetics of the microstructure evolution during fast cooling, providing input for models that aim to predict the behaviour of engineering materials under such conditions. More.

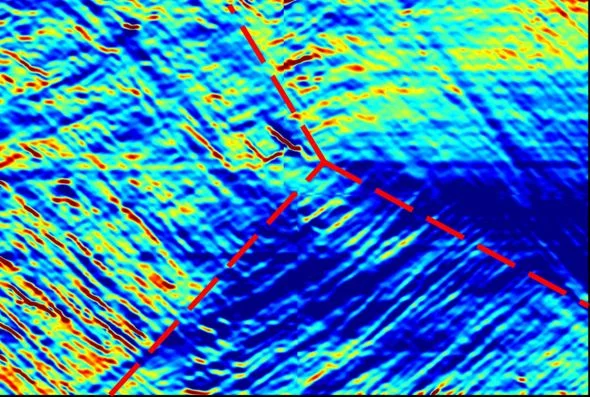

In Situ High Resolution Digital Image Correlation

Digital image correlation (DIC) of images obtained during mechanical testing brings possibilities to study localization of plastic deformation on a specimen surface. This technique has been predominantly used in combination with optical cameras or microscopes. Coupling of DIC with a scanning electron microscopy (SEM) enables to obtain significantly more precise data down to the submicron scale. The results of such experiments can provide important data for further design of materials or manufacturing process optimization. More.

Molecular Dynamics Simulations

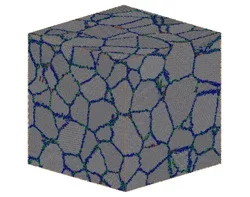

Nanocrystalline (nc) metals are by definition polycrystalline structures with a mean grain size below 100 nm and therefore their microstructure contains a significant volume fraction of interfacial regions separated by nearly-perfect crystals. Compared to its coarse-grain counterpart, the mechanical behavior of a fully-dense nc metal is characterized by a significantly enhanced yield stress and a limited tensile elongation. From the early beginning of experimental investigations in the mechanical behavior of nc metals, it has been proposed that the small grain sizes limit the conventional operation of dislocation sources and estimations of strength were made based on simple Frank–Read sources.

With the increase in computational power, one can deform three-dimensional (3D) computational nc samples containing enough grains in order to mimic an nc metal. These simulations have revealed that the deformation behavior is still to a major extent governed by dislocations: however the dislocations are not nucleated via classical Frank-Read sources situated within the grain interior, but are nucleated at GB ledges, with dislocations traveling through the grain and finally being absorbed in opposite GBs. The merit of the atomistic simulations of nc GB networks lies in the revelation of the details of such dislocation mechanisms. Various examples of our contributions to this research field can be found here.

Crystal Plasticitiy Simulations

Crystal plasticity is a meso-scale modeling approach that predicts the mechanical response of polycrystalline microstructures during plastic deformation. These models may account for the material anisotropy, grain texture and morphology evolution, intergranular and intra-granular stresses and strains, dislocation density kinetics, phase transformations, among others. Crystal plasticity models can be used to gain deeper understanding of the material response that is not accessible via experimental approaches. These models work in synergy with microstructure characterization techniques such as electron backscattering diffraction or in-situ digital image correlation, as well as in-situ diffraction experiments during mechanical testing. We have developed a multi-scale crystal plasticity approach to study multi-axial strain path changes in structural alloys. Details of the model and its application can be found here.