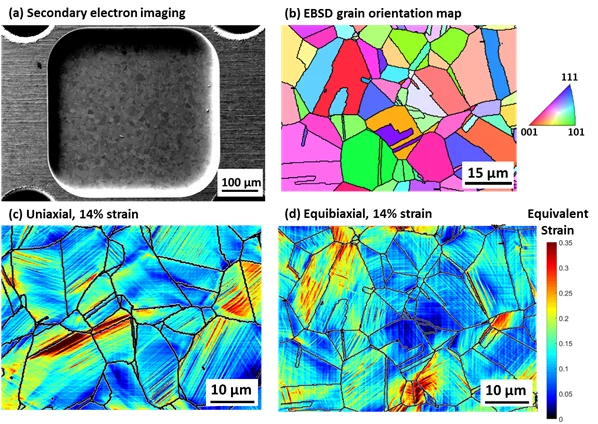

An optimized cruciform geometry is achieved by combining electrochemical micromachining (ECMM) and laser cutting. The center of the cruciform is thinned with ECMM, thus enabling high plasticity at the center during equibiaxial loading, i.e. 25% equivalent strain can be reached in the cruciform. In addition, ECMM process results in high surface quality for metallography. Figure 1a shows the polycrystalline structure of the SS304 revealed by secondary electron imaging with scanning electron microscope (SEM). The surface can also be readily used for electron backscatter diffraction (EBSD) characterization, as shown in Figure 1b. By applying the gold remodeling method described in [1], on the mirror-like surface obtained from ECMM, a fine speckle pattern consisting of gold particles suitable for high-resolution digital image correlation (HRDIC) study can be achieved. We performed in-situ HRDIC study on SS304 to investigate the evolution of slip activity during uniaxial and equibiaxial loadings. Figure 1c and 1d show the slip traces in the polycrystalline structure under uniaxial and equibiaxial deformation respectively. The observed slip traces correspond to the {1 1 1} slip systems and agrees with the Schmid law: the slip system with the highest Schmid factor is firstly activated. Furthermore, equibiaxial loading is observed to introduce more multiple slip activities compared to the uniaxial load, suggesting that under equibiaxial deformation, more shear band intercepts exist which can provide more nucleation sites for martensitic transformation. The HRDIC results provide statistically relevant information at the grain level for the observed difference in the martensite formation under uniaxial and equibiaxial loading at higher strains.

[1] Di Gioacchino F, Quinta da Fonseca J (2013) Plastic Strain Mapping with Sub-micron Resolution Using Digital Image Correlation. Exp Mech 53:743–754

Contact

Eftyhmios PolatidisPhotons for Engineering and Manufacturing Group

Paul Scherrer Institut, Villigen, Switzerland

Telephone: +41 56 310 3948

E-mail: efthymios.polatidis@psi.ch

Prof. Dr. Helena van Swygenhoven

Photons for Engineering and Manufacturing Group

Paul Scherrer Institut, Villigen, Switzerland and

Neutrons and X-rays for Mechanics of Materials

Ecole Polytechnique Fédéral de Lausanne, Lausanne, Switzerland

Telephone: +41 56 310 2931

E-mail: helena.vanswygenhoven@psi.ch

Original Publication

A High Resolution Digital Image Correlation Study under Multiaxial LoadingE. Polatidis, W.-N. Hsu, M. Šmíd, H. Van Swygenhoven

Experimental Mechanics, 2018

DOI: 10.1007/s11340-018-00443-6